Where rival technology meets its limits, the new VLaser 370 takes strides in setting new standards. Incorporating innovative kinematics with smooth movement, future-proofed components, and exceptional thermal stability, the VLaser 370 delivers precision, sustainability, and, above all, impeccable quality and consistency when manufacturing the most demanding cutting tools. Developed for the production of cutting tools with a diameter of up to 150mm, an overall length of 250mm and a maximum weight of 10kg, production can be automated with the adoption of the proven HC4 or HC4 Plus systems that facilitate up to 158 or 160 tools, respectively.

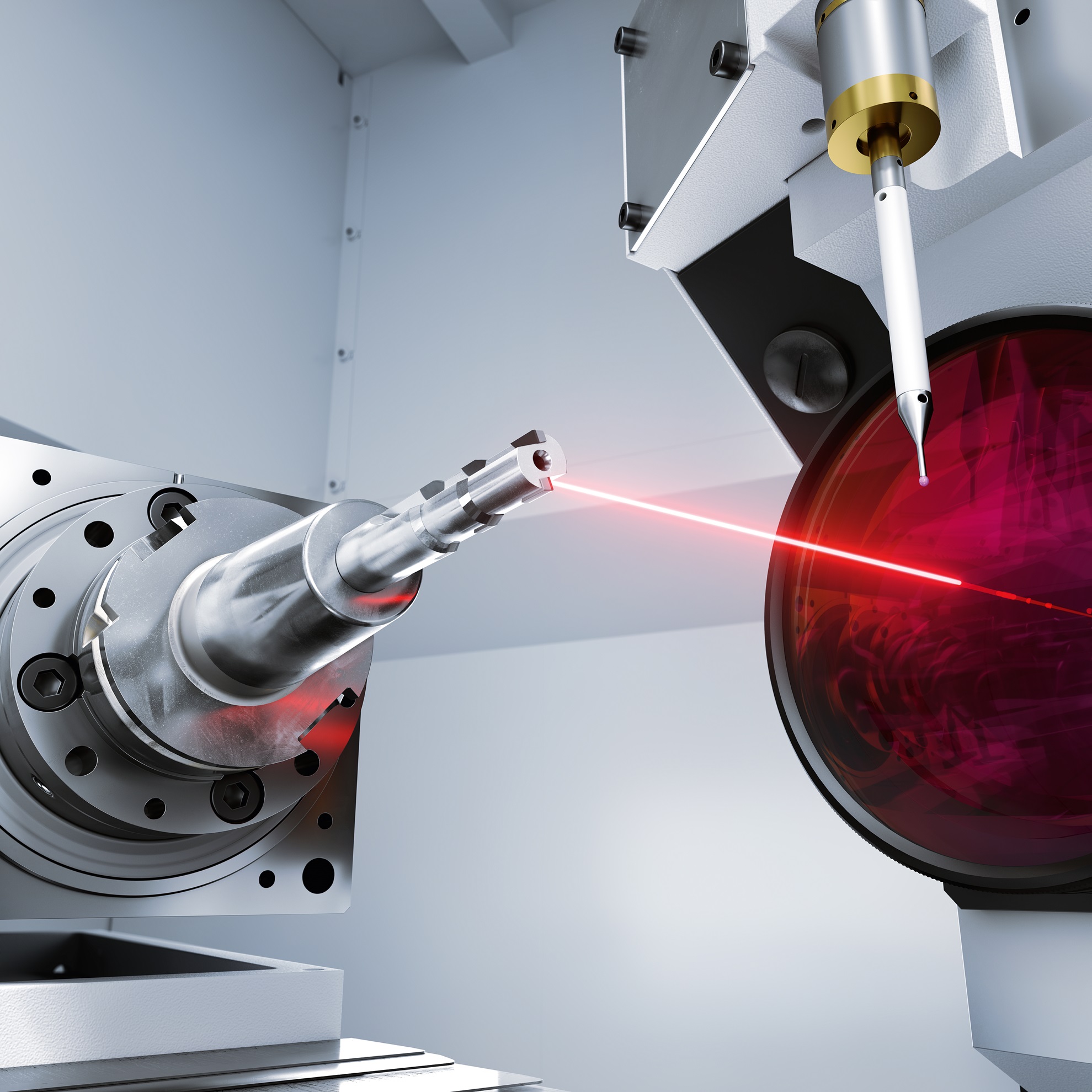

Already proven to be up to 50% more productive than rival technology, the VLaser 370 offers precision in the micron realm with forms as precise as 0.002mm already demonstrated in field tests. The concept of the VLaser 370 is that everything rotates around the laser at the rotation point of the C-axis, The five axes and a laser with fixed beam guidance enable fast and precise machining at the centre point of the machine.

From an ease-of-use perspective, the VLaser 370 enables direct clamping of tools in the A-axis regardless of tool length. The VLaser 370 improves handling and accuracy by eliminating the need for tool extensions. Additionally, the ability to incorporate a counterpoint enhances stability and precision even further, especially when processing particularly long tools that demand the utmost precision. For anyone already familiar with the VOLLMER EDM operational system, the VLaser will be a breeze. With the same operating philosophy, the intelligent and intuitive interface also enables programmes to be transferred from existing VOLLMER EDM machines.

As manufacturers become increasingly concerned by sustainability and operational costs, VOLLMER has reduced energy consumption by more than 40% with the new VLaser 370. The groundbreaking laser technology, optimised kinematics, and efficient drive technology contribute to this staggering saving, which is epitomised by a machine that is independent of consumable costs.

Enhancing productivity with its flexible automation systems, the VLaser 370 is perfect for running unmanned around the clock and at weekends. With an Industry 4.0 gateway integrated as standard, manufacturers can enjoy a seamless data flow between the machine and the digital environment – optimising processes, minimising downtime and eliminating errors.

All this culminates in what is the industry’s most flexible machine for manufacturing cutting tools. Whether it’s tools for the automotive, aerospace or electronics sector, the VLaser 370 can accomplish it all. Through its exceptional precision, extremely small internal radii can be processed as can the most complicated of internal and external forms. From standard tools to the most complex geometries and step tools, the VLaser 370 can process the hardest materials with impeccable surface finishes and edge quality in the μm-range. Furthermore, different cutting-edge treatments can be individually selected for consistent tool performance and durability, whilst large area chip breakers can also be created through parameter entry of STL imports.