As part of the Codem Group founded 15 years ago, Codem Composites has transformed its business model. The company located just south of Peterborough has shifted to single-shift working to now operating 24/7 and it is inundated with work to the point that it has just invested in a brand-new 5-axis machining centre to cope with the increase in demand. What has instigated this rapid growth – the company has invested in OPEN MIND Technologies hyperMILL CAD/CAM suite.

As an engineering technology group that originally focussed on the development of advanced material applications for the defence, automotive and motorsport industries, Codem Composites has embraced additional technologies to broaden the provision of its engineering solutions to service more complex problems across a wider range of markets. The company that operates out of a 30,000sq/ft facility now offers end-to-end solutions for a diverse range of industries and applications.

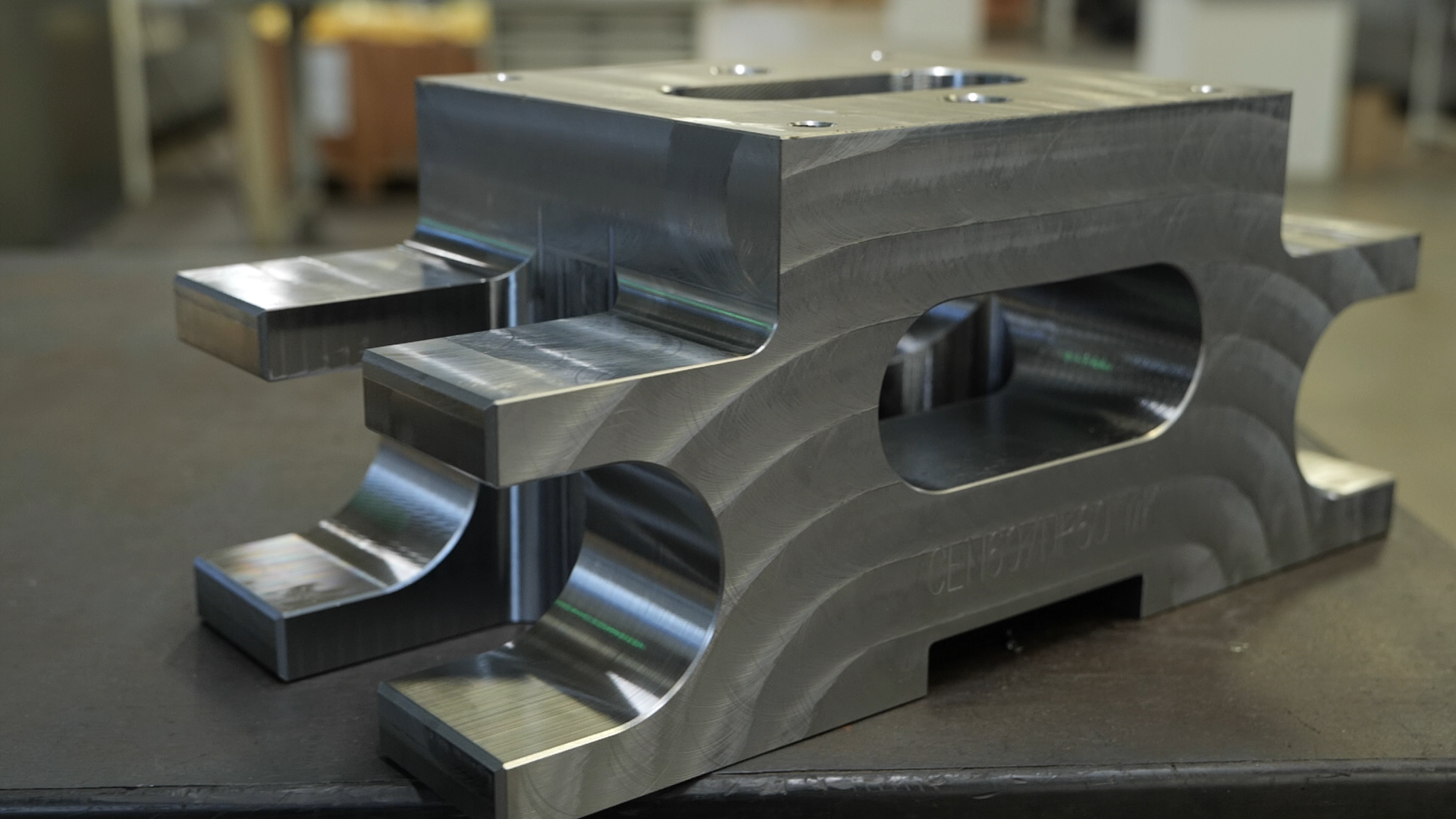

The CAM & Manufacturing Supervisor at Codem Composites, Mr Ryan De’ath explains the process flow for theISO: 9001 certified company: “We produce composite parts for a wide variety of sectors from motorsport through to defence. Anything that the customer wants manufactured out of composites, we can do it. The life cycle of a component that comes through this facility will initially start with a tool or pattern design being generated before entering the machine shop where we will manufacture to the customer’s exact requirements. Once this goes through our machine, it will be hand-finished and sealed before being laminated, cured and then trimmed before inspection and delivery to the customer.”

“It is absolutely essential for us to have a CAM system when you consider the complexity of parts that we are dealing with. We are using hyperMILL from OPEN MIND Technologies and it has completely changed the way that we do things here. We have gone from a 5-axis machine with a bottleneck to confidently investing in the second machine – this is all because we have invested in hyperMILL from OPEN MIND.

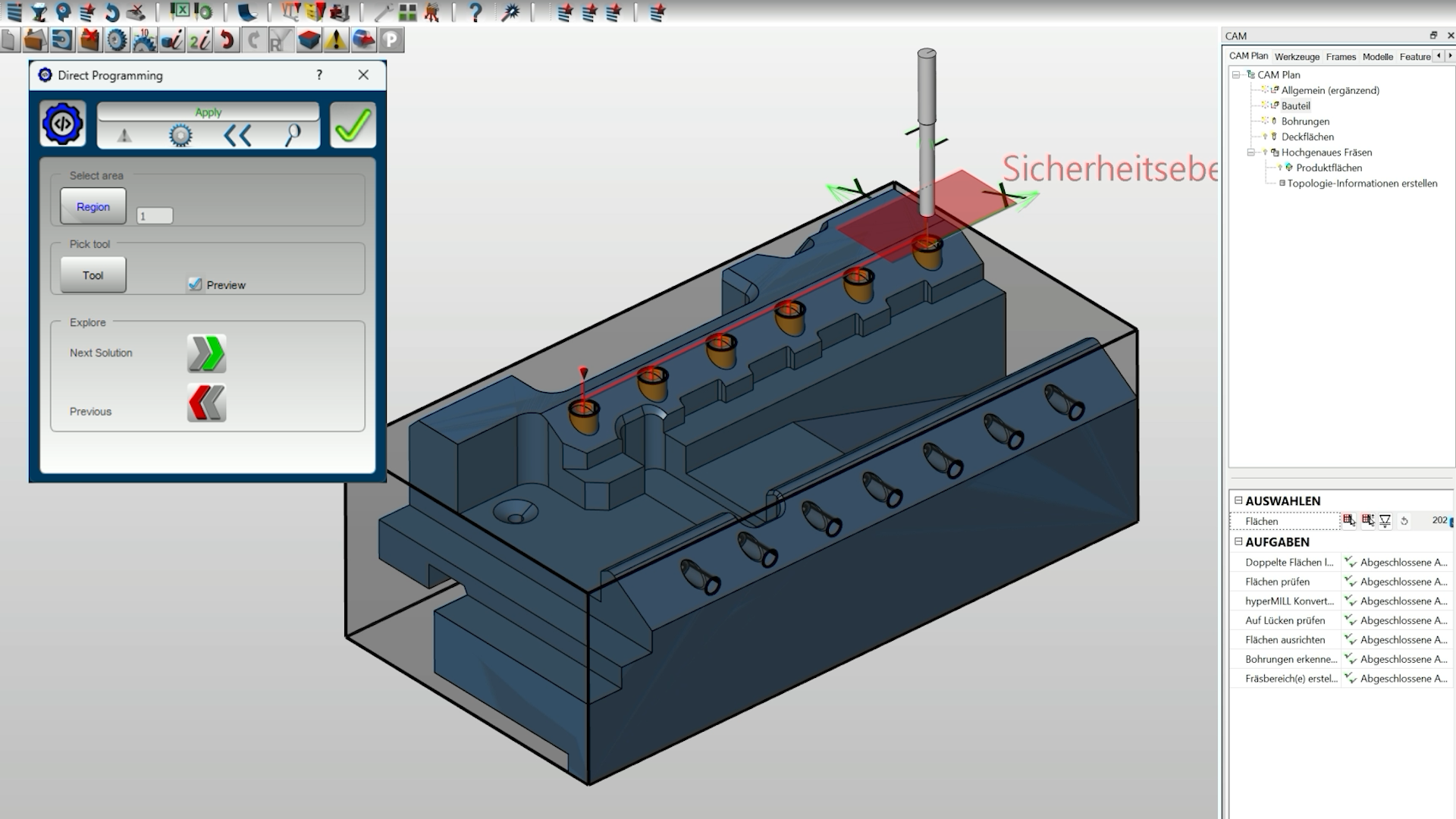

When reviewing CAM systems, Codem Composites looked for features that would be tailored to their business requirements. Discussing this, Ryan continues: “We invested in hyperMILL with the modules for simultaneous 5-axis machining, something we weren’t previously able to do with our other software vendor. We are also running OPEN MIND’s Virtual Machine. That has been a game-changer for lights-out running. It gives us the confidence to leave the machine unattended overnight.”

Looking back at the decision to invest in hyperMILL from OPEN MIND, Ryan continues: “Two years ago, I was using the software that our company had in place and I suggested that we company consider hyperMILL to improve efficiencies in our workflow. With the previous software, parts were running one at a time during the day and the machine would then be switched off at night. By implementing hyperMILL, we have been able to increase efficiency hugely by having unmanned overnight running and also machining multiple parts in a single set-up on the large bed machine.”

Looking at the workflow at the Cambridgeshire company, Ryan adds: “hyperMILL has enabled us to schedule our workflow much more efficiently. We can run smaller jobs during the day and larger batches of work unmanned overnight. It’s really important to run unmanned overnight to maximise the capacity of the machine. With hyperMILL, we can set up the machine with a batch of tools and return to finish parts in the morning. This enables us to move straight to the hand-finishing processes.”

Commenting upon how Codem Composites apply hyperMILL, OPEN MIND UK Sales Director, Ken Baldwin says: “Codem have now been using hyperMILL for almost two years, investing in a 5-axis hyperMILL licence and also the Virtual Machine module. They are machining composites with a Belotti FLU 2617 gantry-type machining centre and they had a bottleneck where the machine sat idle for too long. The issue was that they could not program the parts quickly enough. hyperMILL immediately enabled Codem to program the parts a lot faster whilst the Virtual Machine module provided confidence to run the parts on the machine tool the first time without any prove-out.”

Alluding to the benefits of implementing OPEN MIND’s hyperMILL suite, Ryan continues: “One of the benefits of using hyperMILL is its integrated CAD tools that enable you to extend surfaces and cap holes. You can do all manner of things in the software. Previously, we had to make those surface edits and then export and import them. Now, we can do things ‘live’ and as it is happening. So, when you are programming you can make that decision and make edits immediately. This makes life a lot easier and there is no ‘back and forth’ with other software – everything is controlled within the same programming environment, saving huge amounts of programming time.”

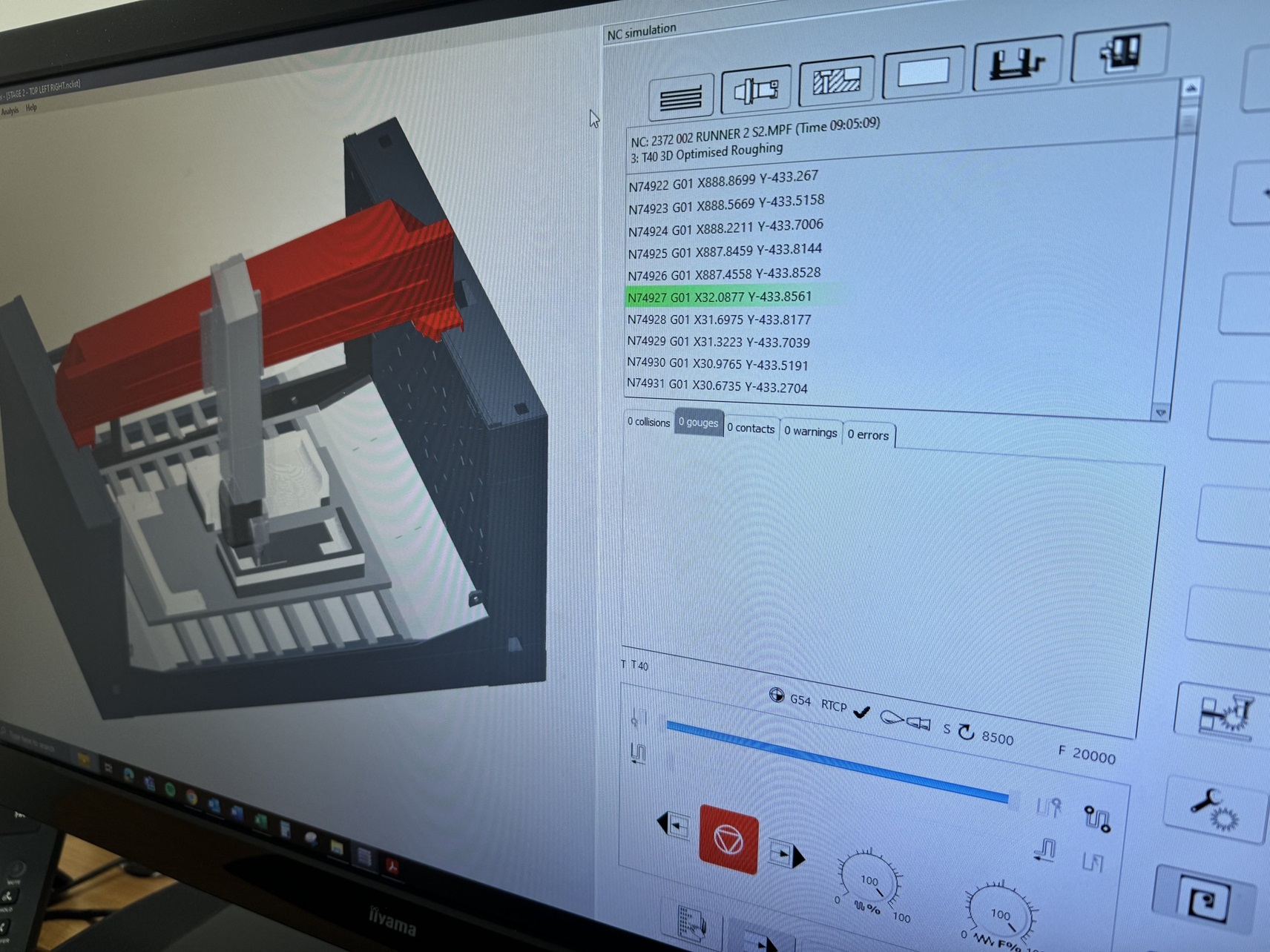

As a company that has invested in OPEN MIND’s Virtual Machine module, Ryan says: “This has been an absolute ‘game changer’ for us, particularly when it comes to looking at our overnight running. It allows us to program a part, put it through the Virtual Machine – and once the Virtual Machine says the program is okay, we can run it with 100% confidence.”

Looking at Virtual Machine in more depth, OPEN MIND’s Ken Baldwin adds: “Virtual Machine is where we create a digital twin of the machine tool. This gives us the exact parameters of what the machine is capable of – and what its limits are. Virtual Machine will simulate the tool path by actually simulating the NC file. When we create an NC file in Virtual Machine, it will apply optimisation to the NC file before it is simulated. What this means in terms of optimising is that rather than have the operator make decisions about the position of the 5-axis head as an example, where there may be a collision in one area and not another, the user doesn’t have to teach the software. The software makes that decision for you and then optimises the tool path in terms of retracts to make sure the tool stays as close to the job as possible – rather than going back to the home position. This makes the tool path as efficient as possible without any input from the user.”

Ken suggests: “Machine tools should be as efficient and productive as possible. So, rather than investing in a new machine tool, manufacturers should be looking to get machines running at their absolute capacity before committing to that additional investment. Machine tools take up a lot of floor space and consume energy. So, if you can make your machine as productive as possible and get more parts off it in a certain period, then when the machine is at capacity it will be time to invest in additional CNC machines. Just like Codem has done.”

Looking at the impact of hyperMILL, Ryan concludes: “Company growth is happening right before my very eyes. We have implemented the hyperMILL software so that we can use our Belotti FLU 2617 machine more efficiently. The result is that we have invested in another Belotti machine to go alongside the first one. This will increase the production work that we can deal with.”

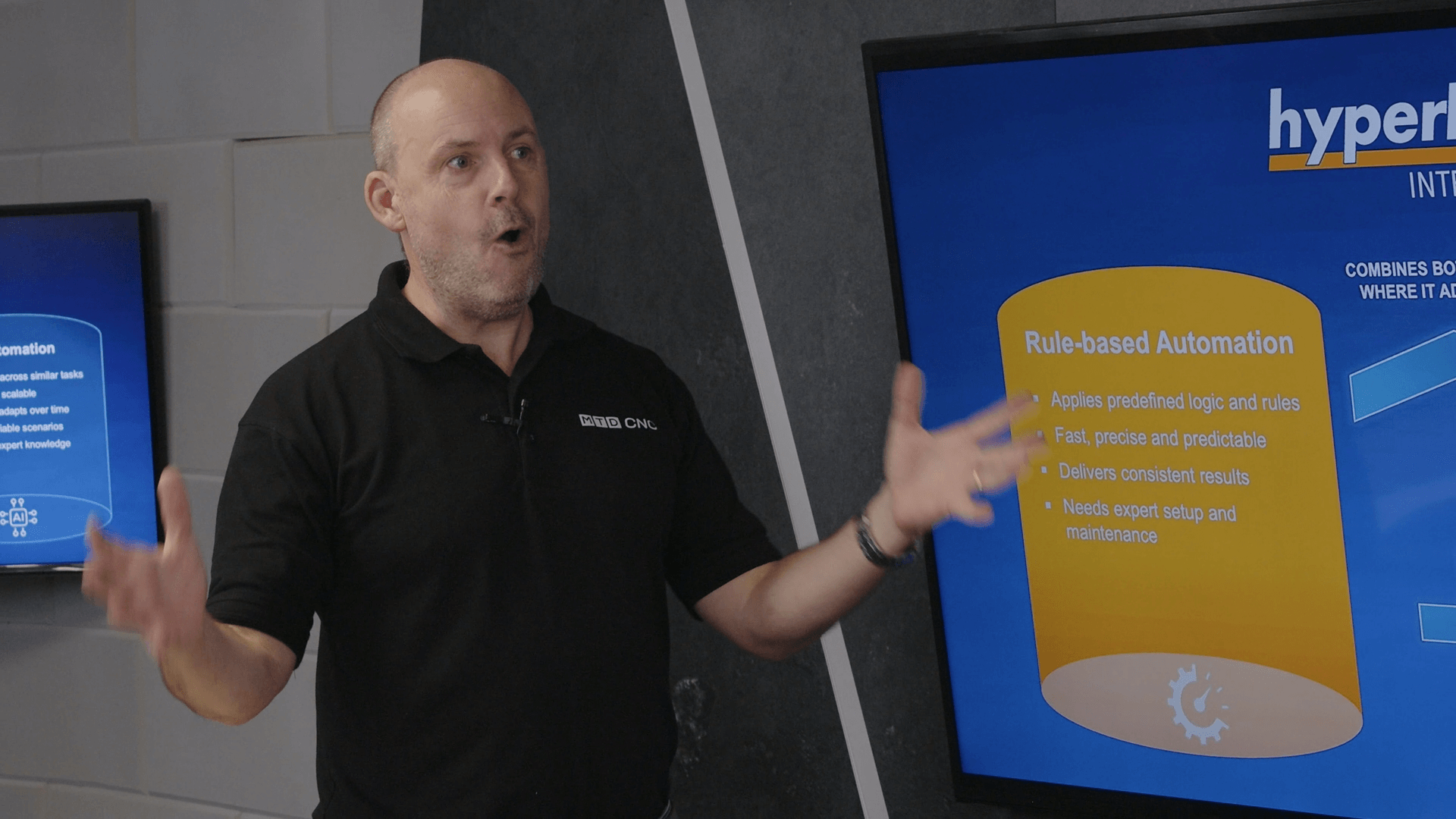

Looking to the future, OPEN MIND’s Ken Baldwin concludes: “When customers are experienced in hyperMILL, the next level to look at is automation. This is the automation of creating tool paths. With hyperMILL, we have invested heavily in automation and some tools enable users to write functionality for the individual user. This enables automation to undertake repetitive tasks for you and it creates the NC programs even faster than before.”