Since 2008, Thyssenkrupp Rothe Erde has received six Dörries CONTUMAT vertical turning and grinding machines from Starrag. Satisfied with the results, the world leader in large-diameter anti-friction bearings that are used in wind turbines has now ordered the same model again – but with two modified and optimised features.

Without large-diameter anti-friction bearings and rings from Thyssenkrupp Rothe Erde, many wind turbines would not be turning. These parts are used in the drives of nine out of ten wind turbine manufacturers worldwide. The industrial company is continuously working on improvements to its production to maintain and expand this leading global position.

Continuous optimisation and innovation are therefore part of everyday life at Thyssenkrupp Rothe Erde Germany GmbH in Lippstadt, which manufactures large-diameter anti-friction bearings. The finishing of the bearings is now carried out on seven Dörries CONTUMAT vertical turning and grinding machines.

In 2021, the company took delivery of a larger Dörries CONTUMAT VC 6300/500 MC F. This machine has also proven to be an instrumental addition. Dipl.-Ing. Hubert Erz, Senior Consultant Sales Renewables at Starrag says: “Despite a fundamental satisfaction with the familiar machine concept, the experts in Lippstadt understand that new technological challenges require modifications.”

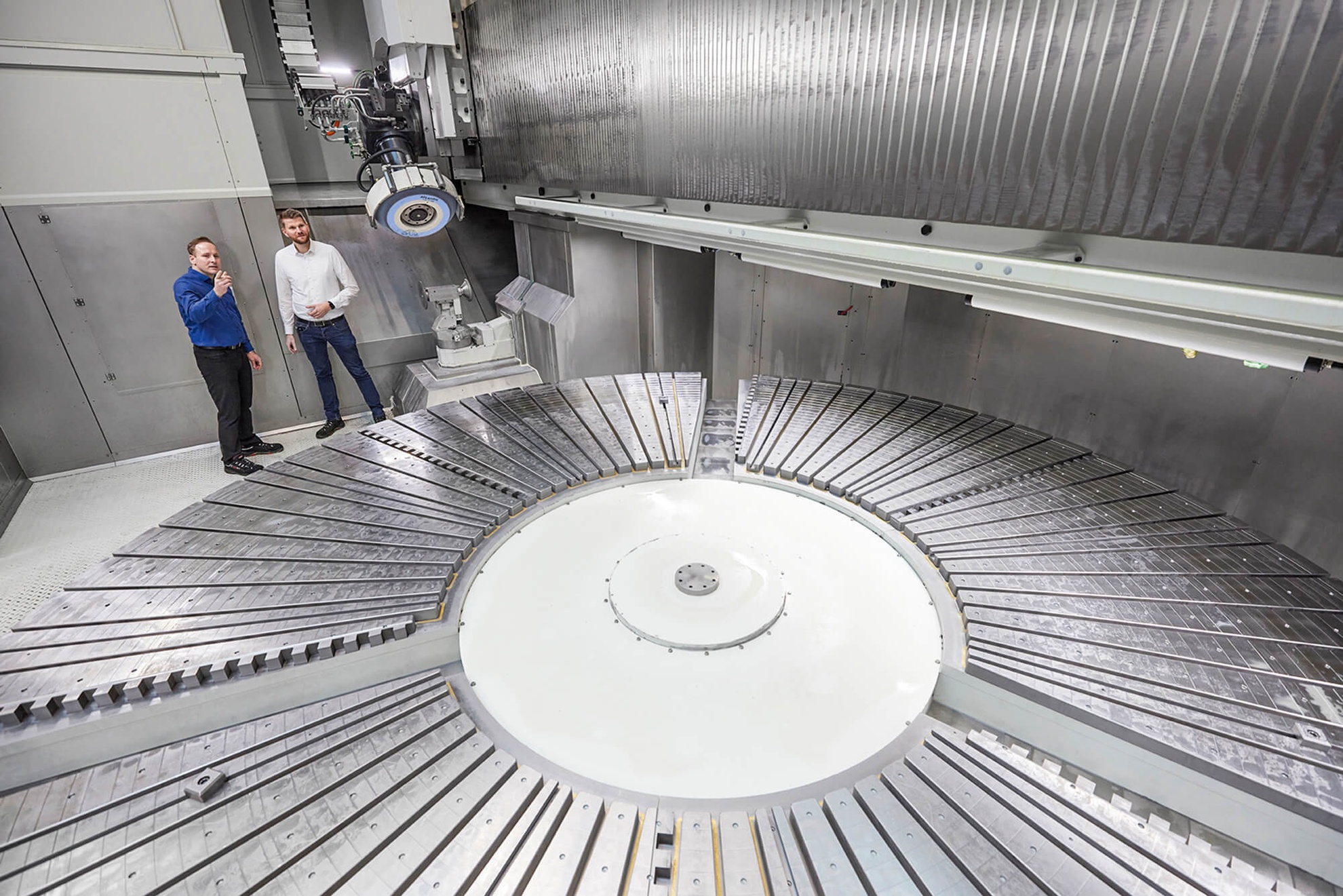

The plant in Lippstadt therefore ordered the machine with some important new technical details that Starrag has improved. For example, the portal of the machine is designed to be larger than is currently required. The newly installed base supports a base table which holds a magnetic chuck with a 5m diameter. The base table can be extended to 6m using ring segments. This allows it to support a larger magnetic chuck. “The machine can be adjusted in size. It therefore fits in with the current trend towards ever larger wind turbines and thus larger anti-friction bearings,” explains Erz.

For future machines, there are even conversations of an extension to 7m. Although the basic machine configuration corresponds to the predecessor model, the supports have been completely revised at the customer’s request. Starrag installed a new grinding support on the left with a centrally positioned motorised grinding spindle. Instead of a separate motorised drilling spindle, the turning/drilling support on the right-hand side was fitted with an integrated drilling spindle with HSK 100-A tool holder. This sits between the two turning tool holders from Kennametal. Customer advisor Erz continues: “We have designed the tool holder of the right-hand support in such a way that the modular size KM63 turning tools and the rotating HSK 100 tools can be picked up directly from a pick-up magazine, meaning an additional drilling unit is no longer required.”

Feedback from operating personnel was also the impetus for numerous improvements. For example, Starrag changed the dressing position to eliminate the previous bottleneck to the protective cover. Now, grinding wheels of all types up to a diameter of 650mm can be easily dressed on the left and right. “It is a significantly optimised, universal dresser. The multiple dressing positions allow operators to precisely adjust the dressing process to the grinding operation,” emphasises Erz. Another point of potential improvement concerned the machine enclosure. Starrag therefore commissioned a new manufacturer for the complete enclosure, whose construction and assembly, according to Erz, are distinguished by: “The fact that the company delivers the enclosure ready for assembly and pre-tested and sets it up very efficiently.”

This optimisation was not only well received by management in Lippstadt, Erz reports after an on-site visit: “The machine operators Eduard Abt and Walerij Fabrizius, who have been using the predecessor machines for several years responded as very positive and satisfied with the new addition.”