Fastems integrates AGVs and AMRs for various CNC automation applications while adding extra value with intelligent control

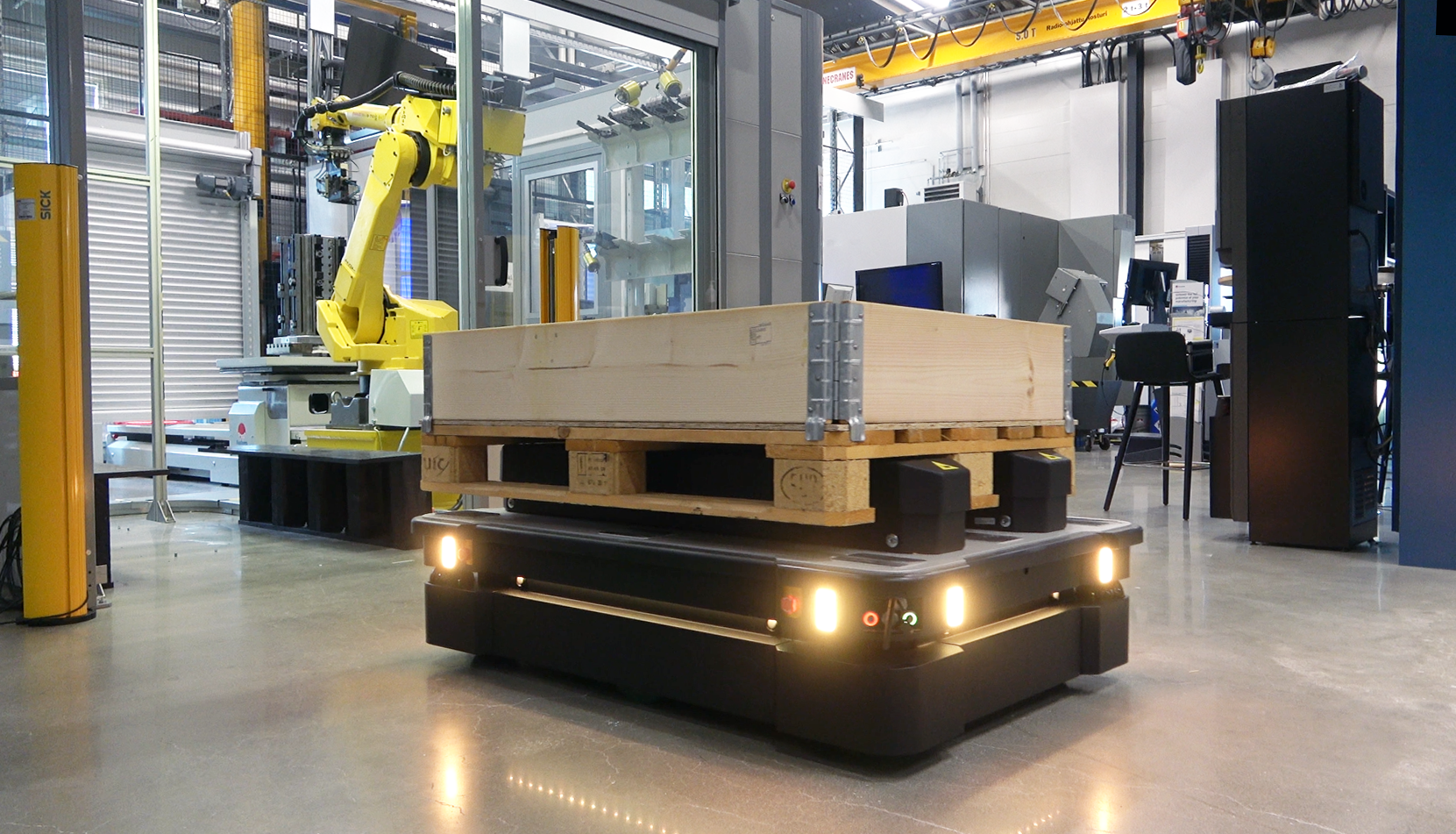

Tampere, Finland 31st August 2022 – Within the past few years the number of Fastems’ CNC automation solutions utilizing AGVs (automated guided vehicle) or AMRs (autonomous mobile robot) has multiplied and the demand keeps rising. The use cases are various: the most typical AGV applications are material intralogistics, delivering tools to machines, and moving machining pallets between production process phases. The common goal of all the AGV projects is timely, safe, and economical transfers of production items.

“Today, the majority of our customer industries are using AGVs or AMRs in some way. Whether in aerospace, defense, machine building, medical or subcontracting, there are automated vehicles in many production premises”, says Mika Laitinen, Solution Sales Director at Fastems. “When it comes to CNC automation and AGVs or AMRs, they can be of great help to reduce manual transfers and forklift operations, reducing buffer sizes, increasing the automation level, and making the production flow more predictable and reproducible.”

Fastems’ Manufacturing Management Software (MMS) brings the needed level of intelligence to AGV use by overseeing all the production orders and resources – and scheduling every piece of this complex puzzle for timely customer deliveries. In practice MMS schedules production based on the customer orders and available production resources such as machine tools, cutting tools and raw materials – and prompts the AGV’s fleet management software to perform the right transfers at the right time.

“We can ensure that all the AGV transfers are done just in time. The benefits are reduced buffer storage sizes between process phases, and employees being able to prepare the right production resources in advance to reduce machine waiting times. And when the unexpected happens like a tool is missing, an urgent customer order comes, or machine breaks, MMS notices it real-time and adjusts the production – including the AGV moves – so that the most urgent jobs still get done in time and all the needed resources are in place in time.”

In addition to customer deliveries, Fastems has multiple R&D projects on-going to understand and find the most productive and economical ways of AGV and AMR use in CNC automation. The research scope deals with current customer applications but also looks further beyond. With interfaces already made for several AGV fleet management software and a dedicated in-house interfacing team, Fastems can integrate any AGV brand of customer’s choice. To read more about the topic and see examples on AGV implementations, visit https://www.fastems.com/agvs-with-cnc-automation/.