Common Issues

- Short-term fixes remain add cost.

- Similar issues reoccurring in several projects.

Common Causes

- Not fact-driven and centred on KPIs (quality, lead-time) encouraging quick fixes.

- Corrections often requested from originator preventing optimal solutions.

- History is rarely passed onto new projects

Solution

Efficient issue management system for a continuously improvement

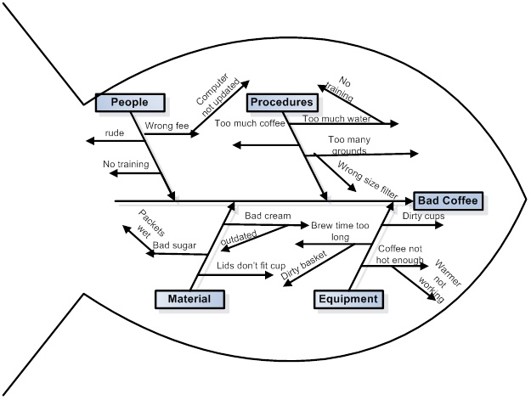

Root cause identification through detailed analysis:

Define the issue with measurable data and explicit context

Analysis to be complete for each level of investigator (Production team, Maintenance, Engineering, etc.) and cross-checked to exhaustively identify the root cause

Confirm sustainability of a corrective action

Effects of a corrective action to be anticipated and measured. Data collection to confirm/reject the solution. A corrective action should not lead to a new issue.

Performance & system audit to control issue management efficiency

Maintain corrective actions as new standard process. Issues history to be used for product evolution for new product development.

Use metrics (Rework time, NVA, repeatability, issue age, operating cost, etc.) to assess the efficiency of the issue management.

Severity, occurrence & detection of issues to be measured to keep PFMEA & control plans documentation accurate.