Intending to improve the quality of apprenticeships and technical education for the benefit of all young people, employers and industry as a whole, WorldSkills is an event held every two years to showcase the talents of tomorrow’s engineers. Founded back in 1946, the event now has huge momentum with more than 51 competitions being fought out by more than 1300 apprentices from over 80 countries.

Considered the ‘Skills Olympics’ for apprentices, the WorldSkills UK Team has certainly won its share of success down the years. Mike Watson, the Training Manager for CNC Milling is an engineer at GKN Aerospace in Bristol and a previous UK winner and competitor at the Sao Paulo event in 2015 bringing home a medallion of excellence, the first for CNC Milling. Like any training or academic establishment, support from industry is essential. This is where the cutting tool support from Tewkesbury based Quickgrind has helped.

Currently undergoing the training cycle for the next competition in Shanghai in 2021, the two UK CNC Milling Squad finalists are Abigail Stansfield from BAE Systems and Joel Keen, an apprentice at Roke. The competitors will face-off at a Team selection competition, which has currently been postponed due to Covid, to decide who will be selected for Shanghai 2021. In the run-up to the UK Team selection, the two competitors are going through a training cycle that sees the young learners undertake 5 to 6 hours of remote training via Google Classrooms or Zoom every week with one-week on-site training blocks every two months. This intensifies to one week per month in the run-up to a competition.

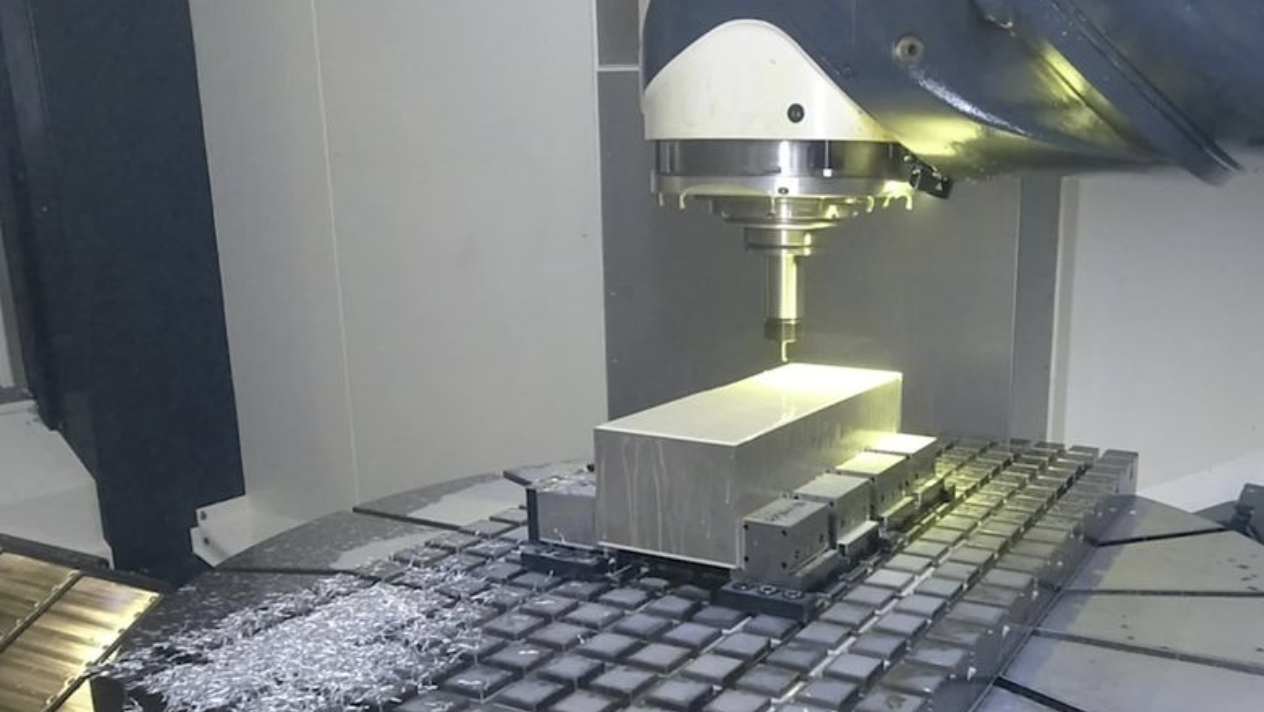

The ‘block’ training is undertaken at numerous educational establishments with Coleg Cambria in North Wales being the primary training hub. The Welsh training facility is used due to its suitable equipment that includes 2 DMG MORI CNC Milling machines, MasterCAM software and Mitutoyo measurement equipment – all sponsors of the global event whose equipment is specified for the competition.

Raising the bar

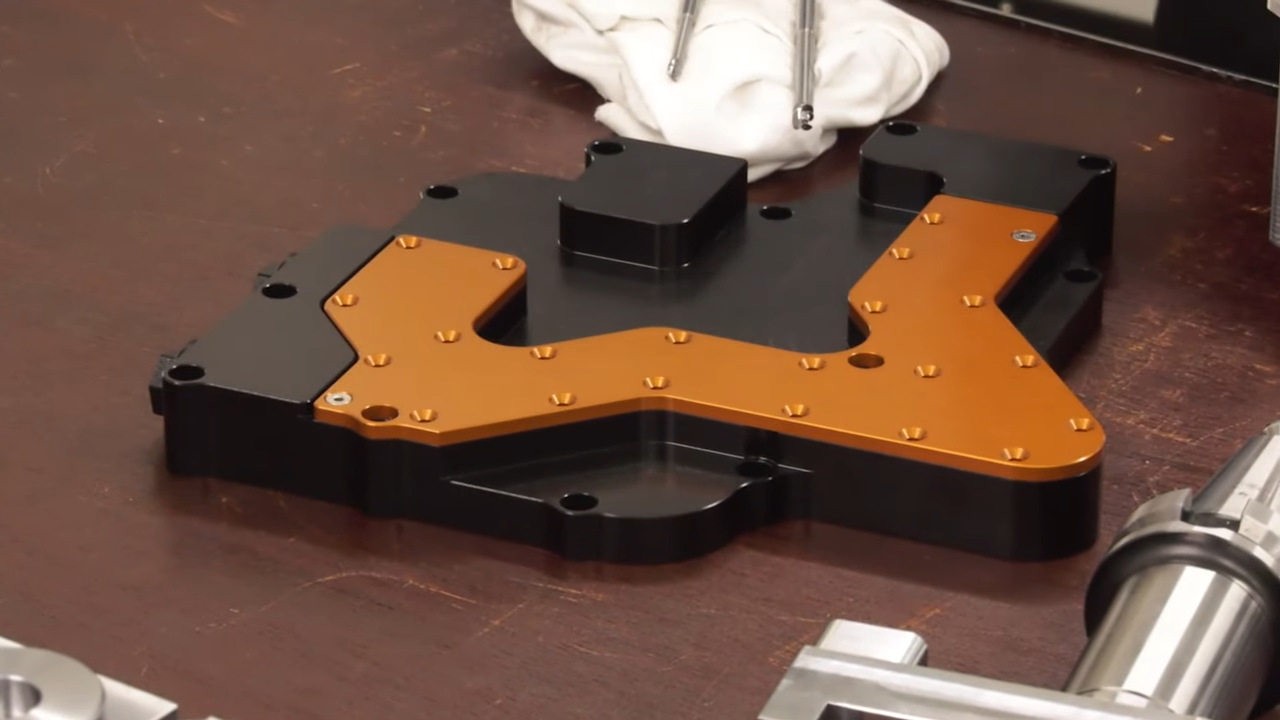

According to Mike Watson, the competitors are undertaking tasks that a lot of engineers would shy away from, saying: “The WorldSkills competition raises the bar. The trainees have three complex geometry parts to machine; an aluminium part and two steel parts with a time limit of 4hours 15minutes and 7hours respectively. Within this time, the trainees have to set-up the machine with workholding and toolholding with up to 20 tool positions set and measured, create a CAD model, program the toolpaths with MasterCAM CAM software and then machine the part.” Whilst some machinists may think this isn’t a problem, the judges marking criteria are based around precision, surface finish, and attention to detail.

As Mike continues: “We have a surface finish of Ra0.8 that we have to achieve with precision levels of +/-5 microns. Whilst this challenge raises the bar quite high, the more precise the part and the better the surface finish, the more likelihood of winning. The surface finish requirement may be Ra0.8, but under competition conditions, we aim for Ra0.5 to be “safe”. Likewise, the tighter the tolerances – the higher the overall assessment mark. This very high level is why we have started working with Quickgrind under Quickgrind QUEST program with their Quickgrind Educational Support Team for cutting tool support.”

Flying the flag

Playing its part in supporting the engineers of tomorrow and flying the flag for UK manufacturing, Tewkesbury based Quickgrind has provided its expertise and cutting tools to help the apprentices. With only 20 tool positions that must include milling tools as well as drills and taps for both aluminium and steel, flexibility is of the essence. Taking into account the required tolerances and surface finishes, the cutting tools really have to step-up to the task.

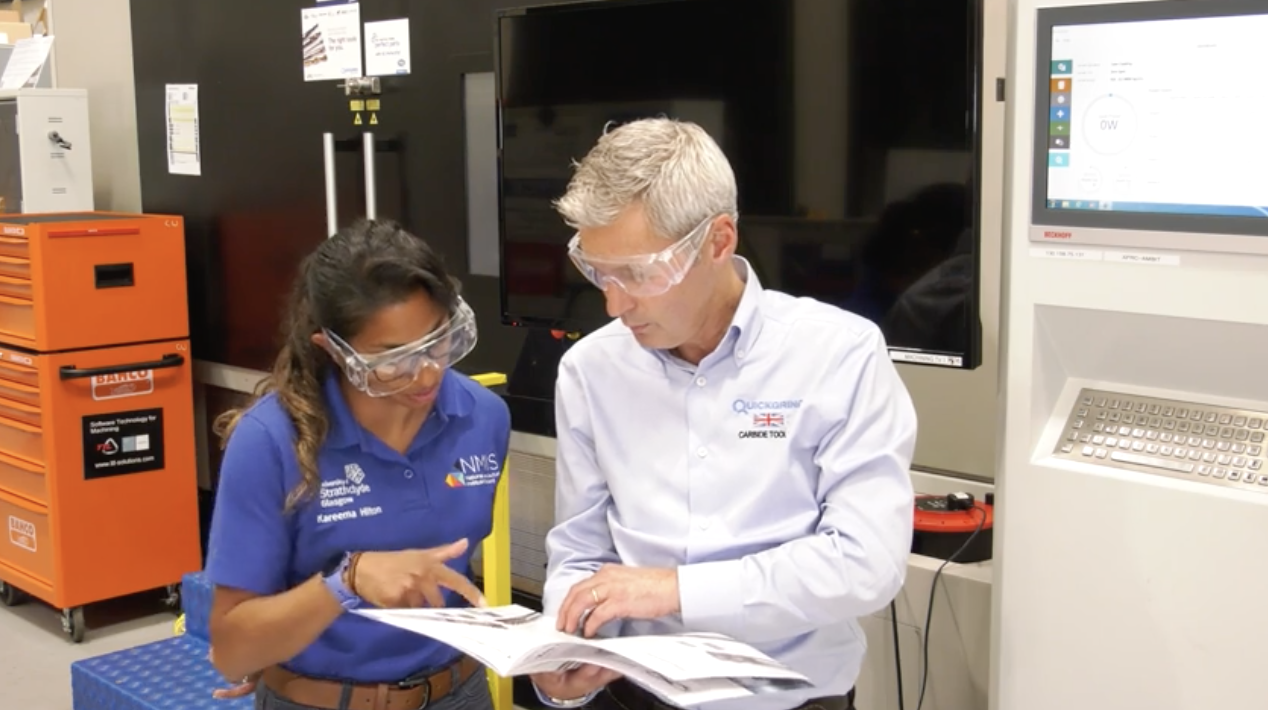

Working with WorldSkills UK, Quickgrind’s International Technical Support Manager, Mr Mark Aspinall says: “The level these apprentices are at is truly impressive. We have worked with WorldSkills UK and the competitors to trial a number of tools and to give the competitors a full understanding of the impact that different geometries, number of cutting edges and coatings can have on performance.”

The trials have included the use of Quickgrind’s Alligator and Caiman range’s of 3-flute solid carbide end mills for aluminium, the Q-Cut and Mirage Series of 4-flute tools for steel machining and more recently the introduction of the Bulldog range of end mills for high-feed machining. The Q-Cut and Mirage have been trialled with varying chipbreaker geometries as well as 5 and 6-flute options. In addition, the tools have been necked for greater reach to provide flexibility for a competitive situation where only a limited number of tools can be used. Because of the use of trochoidal tool paths and high feed rates being used, the unequal helix, variable flute design and strengthened core of the Mirage Series has been implemented for steel machining.

As Mark continues: “At Quickgrind our mantra is ‘Infinite Possibilities’ where every tool is bespoke to the needs of the user. The competitors are now telling me ‘we need a particular tool’ or ‘will you make me a tool with..’ and they fully get ‘Infinite possibilities’. The two competitors are now learning and understanding the impact and purpose of different edge geometries, coatings, chip breakers and numbers of cutting edges can have on different materials. They are also becoming very knowledgeable concerning the impact spindle speed and power, tool holding selection, stability and overhang have on the ability to achieve high-quality surface finishes and eliminate vibration.”

“The competitors have to hit a minimum surface finish requirement of Ra0.8, but at competition level, Ra0.5 tends to be the norm. Taking this into account, we are now trialling our Demon Series of multi-flute end mills that have been specifically developed for super finishing, so we can hit Ra0.4. At the last training session by implementing the Demon the competitors achieved surface finishes of Ra0.2, so providing these high-end tooling solutions will hopefully give Team UK a competitive edge when flying the flag for UK manufacturing,” concludes Mark Aspinall.