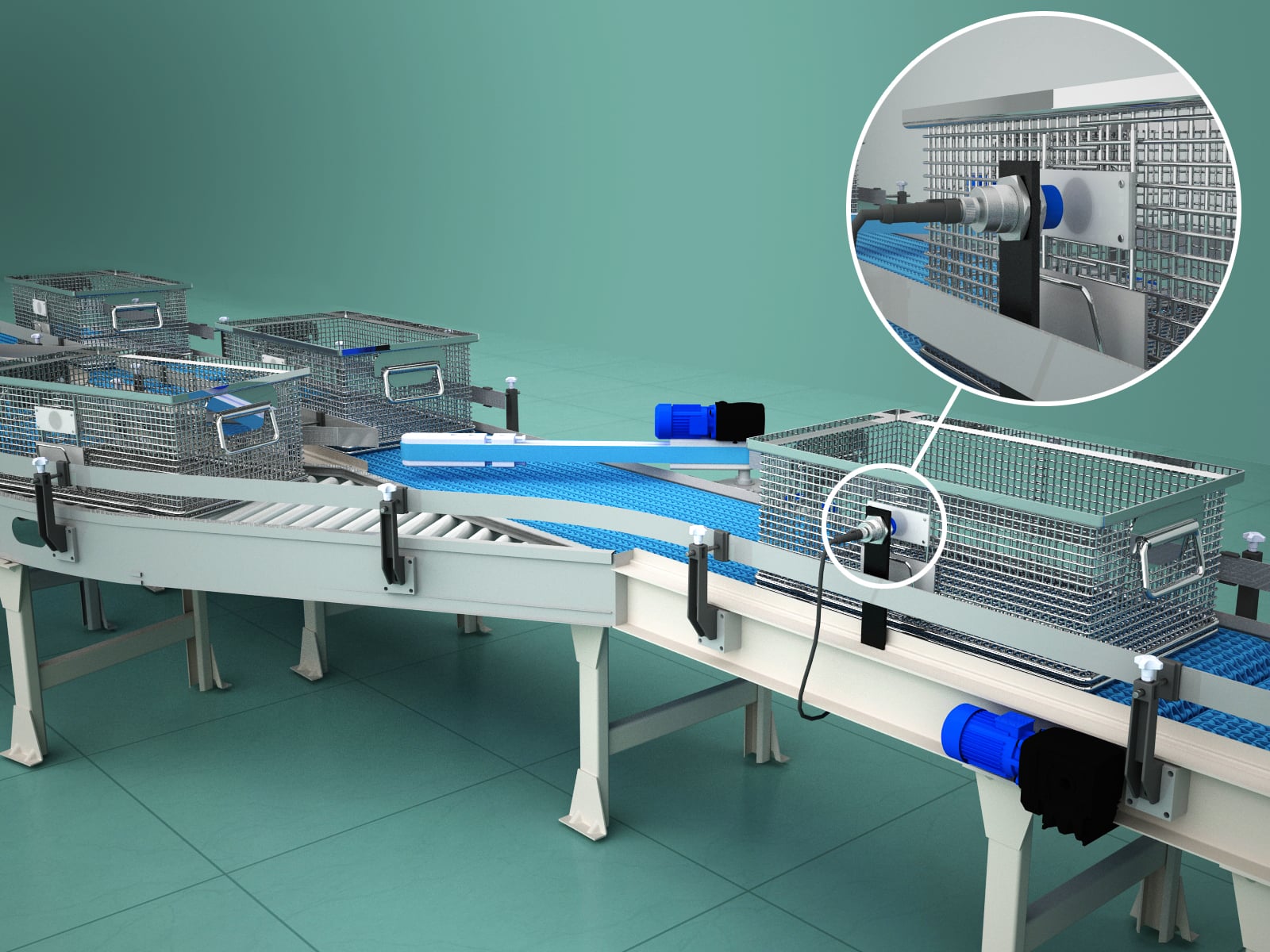

A manufacturer of automated conveyor systems uses RFID technology to monitor the location of items and to route them to their chosen destinations. As an basket, fitted with an RFID transponder tag, travels through the warehouse, IO-Link-enabled high-frequency read-write modules (RWMs) monitor its position and read pre-set data stored in the tag. Local logic capability enables a read-write module to trigger a conveyor diverter, routing the item without reference to a centralised PLC-based control system.

Customer Application

An OEM manufacturer of automated conveyor systems for the distribution sector uses RFID technology to monitor the location of items as they pass through a warehouse.

Designers also required local control of two-way conveyor diverters to route items to the correct destination;. Therefore generic information stored on each RFID transponder tag determines the required diverter position and thus an item’s destination.

Location monitoring relies on a plant-wide PLC-based control system. An industry-standard interface with the RFID modules is highly desirable as this allows the use of existing libraries of PLC function blocks, avoiding the need for custom PLC code. Ultra-high-speed communication is not essential as conveyor speeds are moderate.

Local diverter switching relies solely on the information contained in an item’s RFID tag; communication with the centralized system is unnecessary. Response time must be no more than 200 milliseconds to allow the diverter to operate before the item reaches the switch point.

Customer Solution

IO-Link-enabled high-frequency (HF) read-write modules (RWMs) and RFID tags from Contrinex are ideal for this application. IO-Link-enabled RWMs are capable of meeting both requirements, allowing commonality of RWM hardware across the entire installation. With data-transfer rates up to 38.4 kbaud (COM2) in IO-Link mode, communication speeds are well in excess of the minimum requirement.

Contrinex IO-Link RWMs are configurable to operate in one of two discrete modes; IO-Link mode allows remote communication via the standard protocol, while standard I/O mode (SIO mode) allows the device to function as a smart condition-detection sensor. Process engineers can switch RWMs between modes either remotely, using the IO-Link protocol itself, or locally, using a pre-configured RFID tag (a Master Tag) which is applied directly in front of the RWM at start-up.

While in SIO mode, RWMs operate either as simple presence-detection sensors, with a single switched output, or as two-state condition-detection sensors with two PNP outputs that correspond to pre-set generic values saved to an item’s RFID. In the event of a match, an RWM instructs a diverter to assume one of two alternative switched positions.

With sensing distances up to 60mm, robust M18- and M30-threaded metal housings and integral M12 connectors, Contrinex RWMs are ideally suited to the environment of a busy industrial warehouse. They are compatible with all ISO/IEC 15693 approved RFID tags, allowing designers ultimate flexibility and excellent value for money.