The Challenge

Typically, robots rely on their repeatability not their accuracy. When a robot first moves to a programmed position it may only get there to within +/- 2mm. It will however always go back to that same position to within +/-0.05mm. This lack of accuracy therefore often leads to a manual commissioning process taking place. When a program is first brought online, an engineer will use the teach pendant stood next to the robot to manually adjust each of the critical program positions correcting for the inaccuracy. This is clearly a costly and time-consuming process that delays the speed at which new products can be introduced into production. It may also waste multiple parts needed for ‘trial runs’ before the system is corrected. This process is also subjective with the engineer on the shopfloor making decisions about what is acceptable which also creates a challenge when handing over to the process owner.

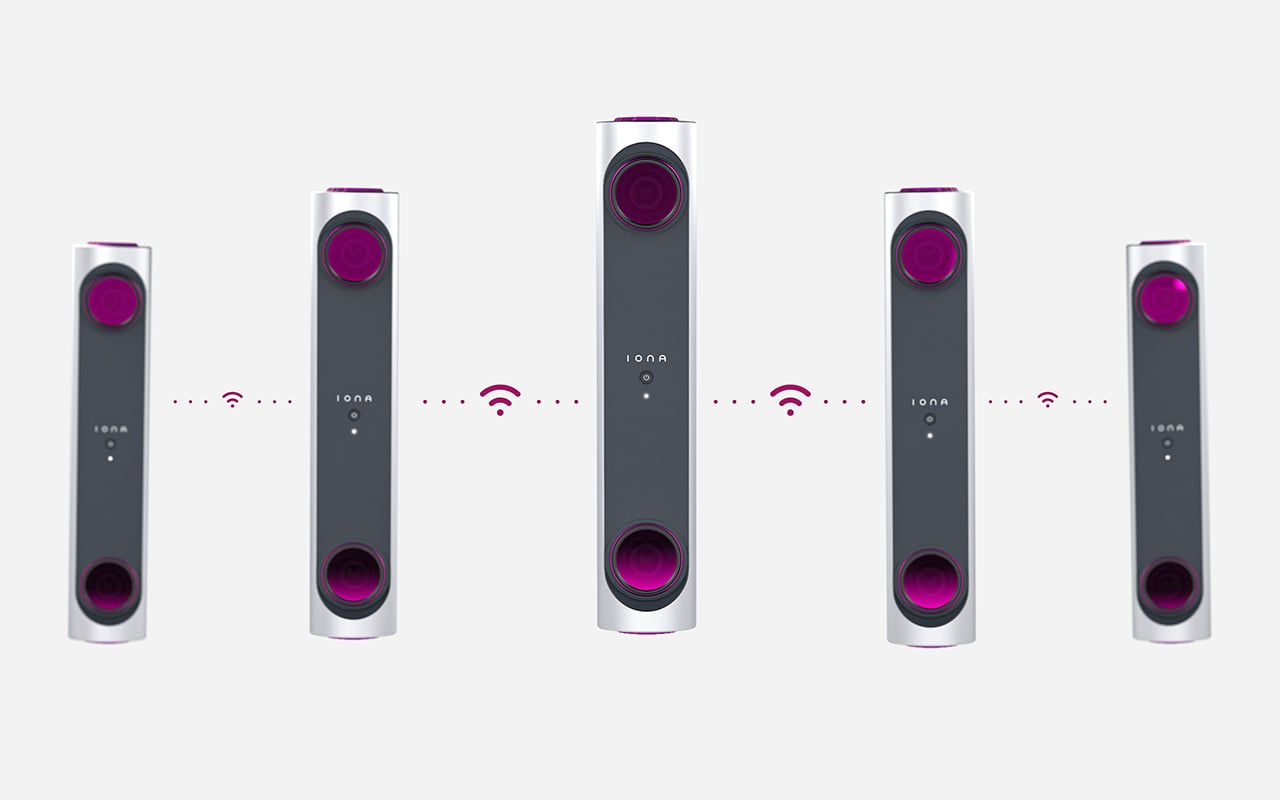

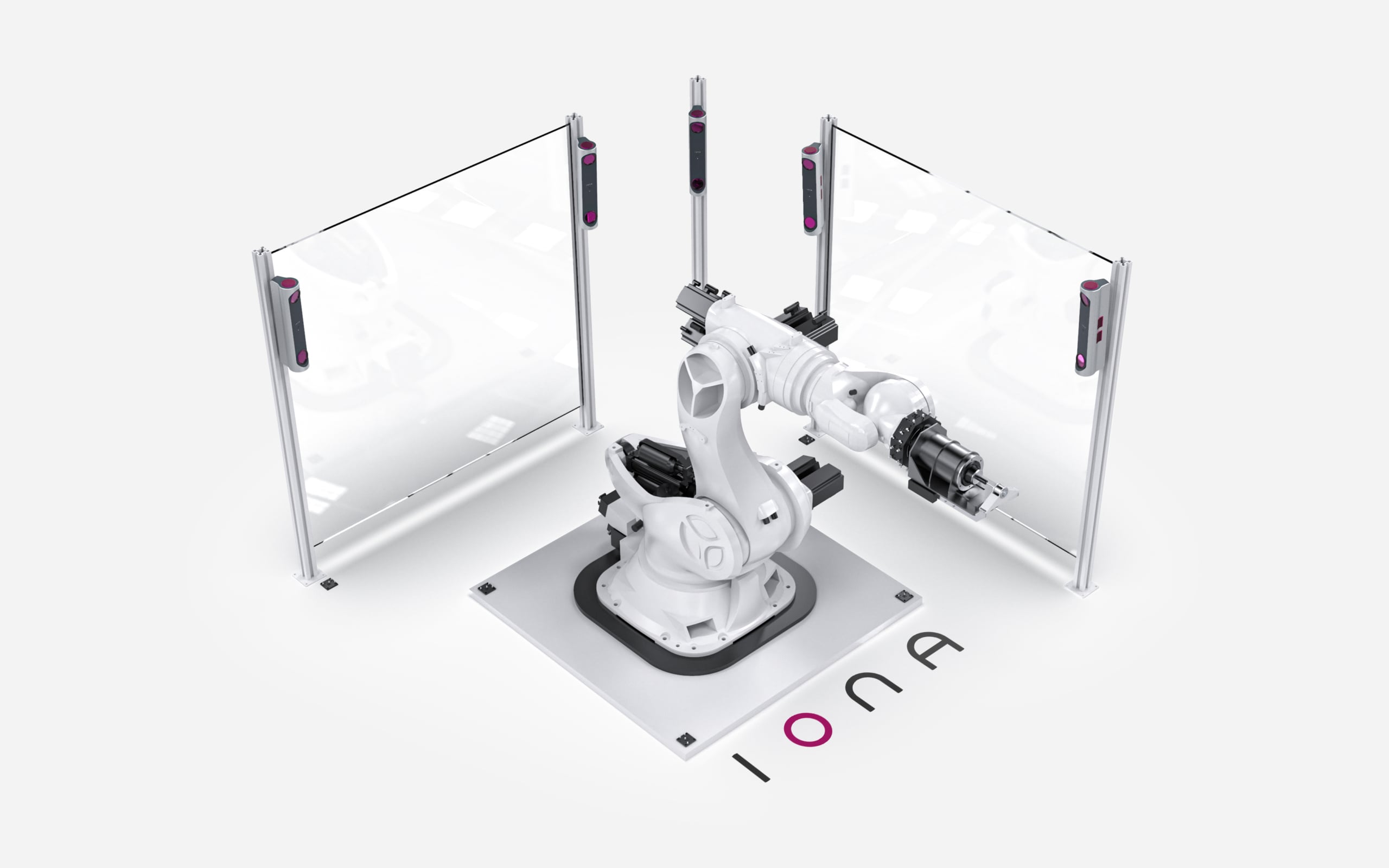

How can IONA help?

The IONA system has a ‘Teach’ module in the ORA software platform. This allows operators to rapidly perform a physical dry run of the program, capturing data using the sensors then using the Teach module to highlight the differences between the intended program and what happens in reality. The changes to correct the program can then be made at the click of a button.

IONA System Outcomes

The TEACH module reduces the commissioning time for introducing a new program change. This is a significant time saving when introducing a new part or model variant. With IONA, program changes or new parts can be introduced more frequently. This also creates a traceable process for program changes and an independent way of validating a robot program.

Discover how IONA can help your business!

Download the Brochure to find out more about IONA and the ways we can help your business