Hel Performance selects Lang automation to increase spindle up time..

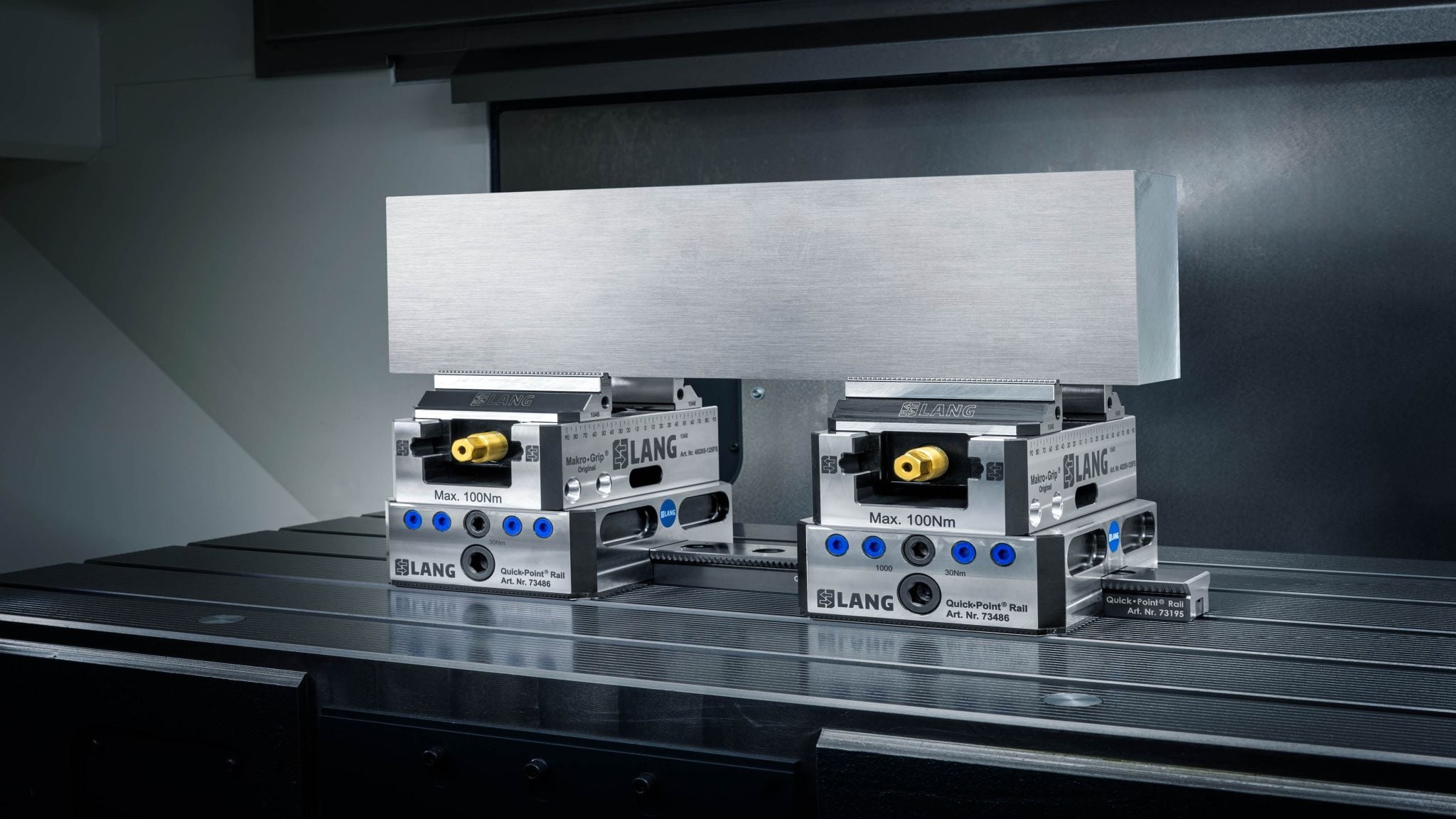

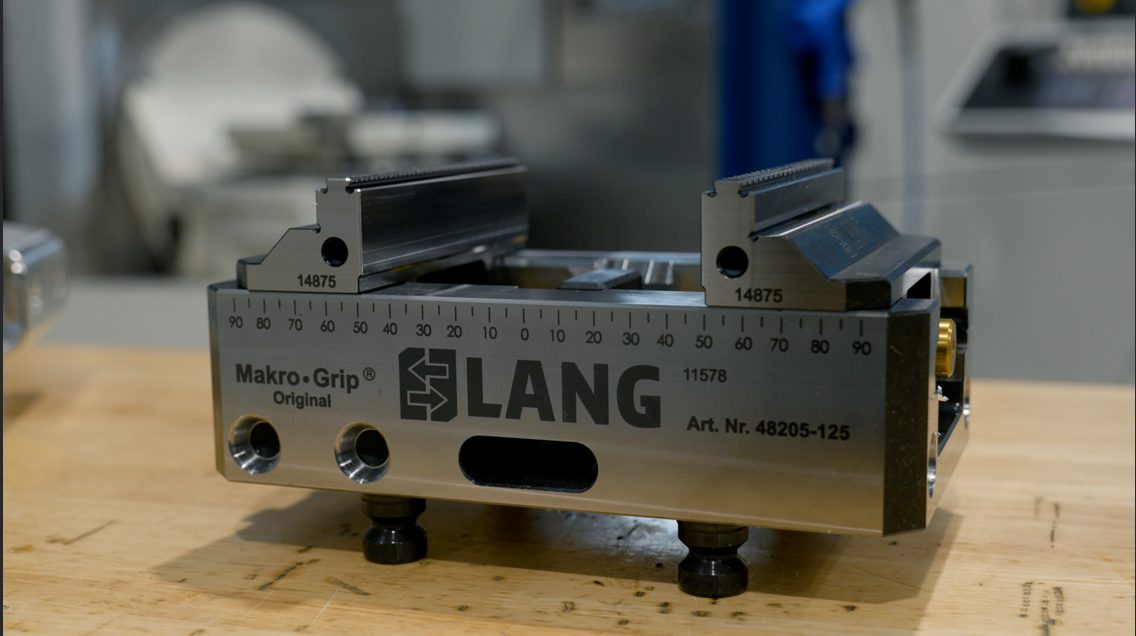

The RoboTrex is automatic handling systems which operate the machining centre from an automation trolley. This also serves as a storage medium for the vices. Depending on the part size, the trolley can store up to 42 vices on a RoboTrex 52 and 16 vices on a RoboTrex 96. Both systems also offer the capability of using up to four trolleys, which means that the storage capacity can be increased to up to 168 vices. The heart of our system is the patented vertical positioning of the vices: it ensures maximum space utilisation and guarantees best accessibility. The external pre-loading of the automation trolleys allows RoboTrex to be re-equipped within seconds. This ensures that there is no unnecessary downtime. RoboTrex offers the perfect solution for existing machine tools with no services to the table as all of the clamping is done via the robot arm. The system arrives at your factory pre programmed so no user input is required. All the operator needs to do is load up the vices and press go.