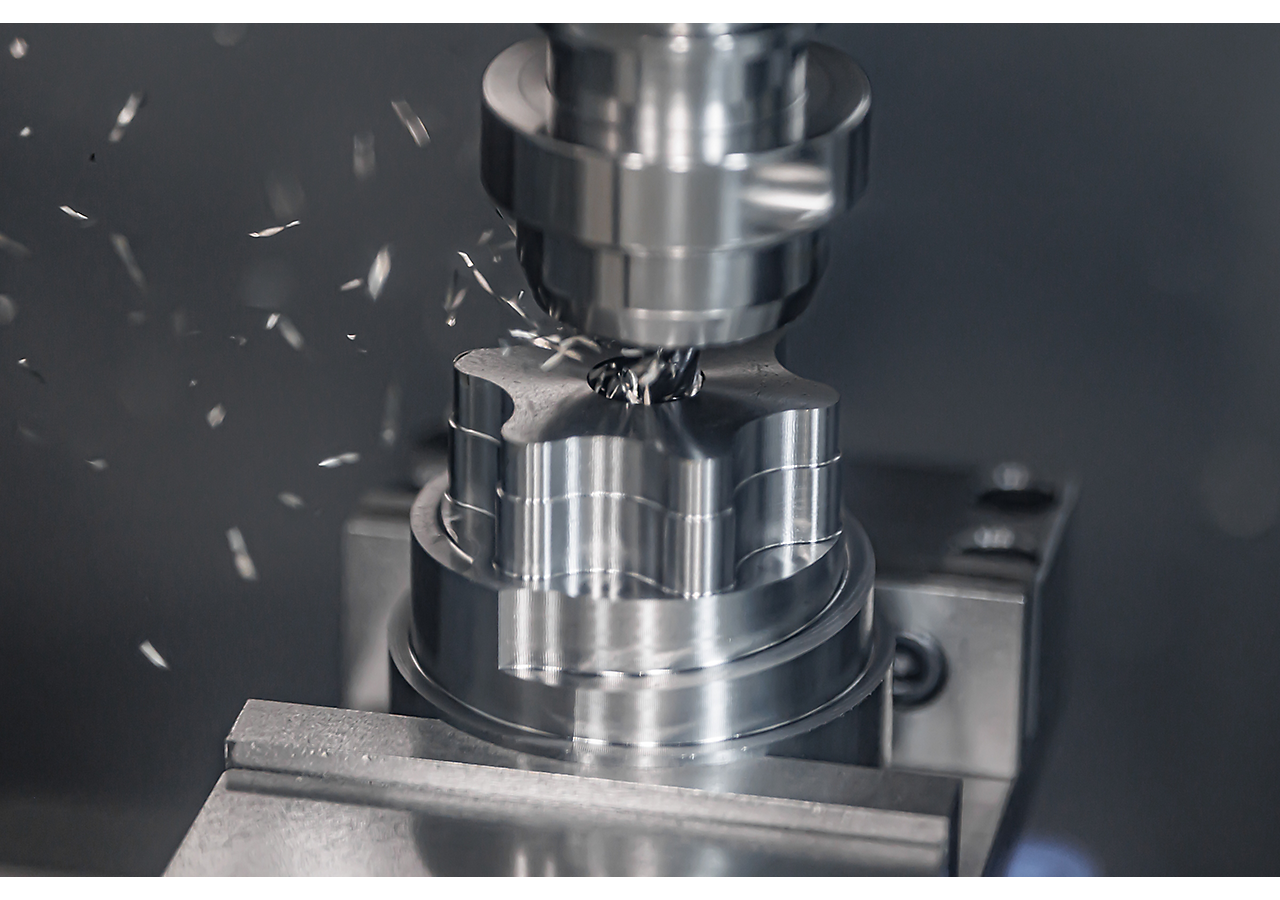

To assert its position as the industry benchmark for aerospace industry cutting tools, Industrial Tooling Corporation (ITC) Ltd has now launched the new Widia range of 4U50 and 4U80 shallow pitch roughing cutters. Perfect for stainless steel and high-temperature alloys, the new solid carbide end mills demonstrate reliable consistent performance at higher machining parameters when conducting prolonged machining cycles on challenging aerospace grade materials.

Designated as shallow pitch roughing tools for high material removal rates in the aerospace industry, the new Widia 4U50 and 4U80 Series is available with four or six cutting edges with a harmonically designed flute geometry and the choice of a short cut length (4U50 Series) for superior rigidity or a regular cut length (4U80 Series) with both enhanced cutting performance and stability when conducting heavy-duty roughing.

The high performance centre cutting solid carbide end mills are coated with Widia’s proprietary AlTiN-MT coating technology that works in synergy with the advanced geometry design to improve machining performance and tool life when cutting challenging heat-resistant alloys.

The 4U50 has a short cut length with a flute length of 6 to 25mm depending upon diameter selected and a necked shank that permits 3XD cutting. The 4U50 is available with cutting diameters of 6, 8, 10, 12, 16, 20 and 25mm with a neck length from 18 to 75mm. The stub length design includes an overall length from 57 to 121mm and this design eliminates chatter and vibration, extends tool life and improves material removal rates. In addition, the tool geometry enhances swarf evacuation and creates a smooth cutting action to reduce stress and load on both the tool and machine spindle.

Likewise, the new 4U80 Series of regular cut length end mills for deep pocket machining are available in diameters from 6 to 25mm with the same overall length as the 4U50. Both the 4U50 and the 4U80 are offered with four flutes in diameters from 6 to 12mm with the larger 16, 20 and 25mm tools incorporating a six flute geometry with a 45 degree helix for rapidly extracting chips from the cutting area. Unlike the stub length 4U50 Series, the 4U80 provides a 3XD flute length from 13 to 45mm that increases the opportunity for high-performance slotting, pocketing and ramping.