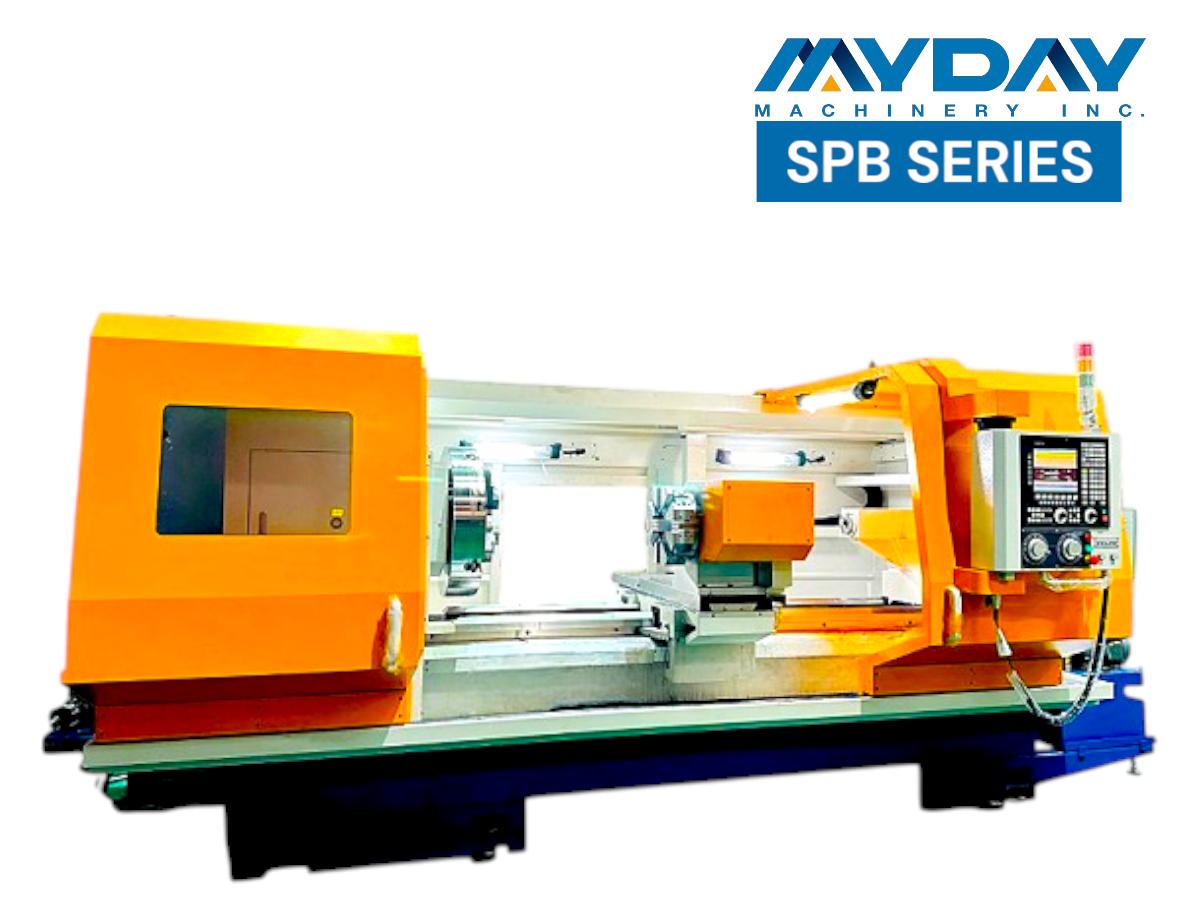

CNC Heavy Duty Precision Lathe(18” Bed)

Thursday 27 March 2025

Supplier Information

MYDAY

Visit Website

Detailed Specification

CNC Heavy Duty Precision Lathe is a very popular product line in metal industry. The spindle motor power in the series is transmitted to the spindle through pulley, belt and 4-step gear sets. It could perform heavy duty machining with high speed and high rigidity.

| Description \ Model | SPB670 | SPB770 | SPB840 | ||

|---|---|---|---|---|---|

| Swing over bed | 670 mm | 770 mm | 840 mm | ||

| Swing over cross slide | 380 mm | 480 mm | 550 mm | ||

| Width of bed | 460 mm (18”) | ||||

| Distance between centers | 1500mm, 2000mm, 3000mm, 4000mm, 5000mm | ||||

| Spindle bore | Ø104mm (4”) / Ø156mm (6”) / Ø230mm (9”) | ||||

| Spindle nose | A2-11 / A2-11 / A2-15 | ||||

| Spindle speeds (4 Steps) | 13-1200rpm / 11-800rpm / 4-600rpm (Chucks are NOT Considered) | ||||

| Ball screw diameter | X-axis : Ø32 , Z-axis : Ø50 | ||||

| Rapid Travel | X-axis : 5 m/min , Z-axis : 5 m/min | ||||

| Max x-axis travel | 410mm | ||||

| Max z-axis travel | 1300mm, 1800mm, 2800mm, 3800mm, 4800mm | ||||

| Tailstock spindle travel / Quill | 230mm / Ø105 | ||||

| Tailstock spindle taper | MT#5 | ||||

| Controller | FAGOR 8055i | FANUC 0i-TF | SIEMENS 828D | ||

| Spindle motor | 15KW (FM7 A150) | 15KW (αi15) | 15KW (βi15) | 15KW (1PH8133) | |

| X-axis servo motor | FKM 42 (1.9KW) | αι8 (1.6KW) | βι8 (1.2KW) | 1FK7060 (1.1KW) | |

| Z-axis servo motor | FKM 44 (3.6KW) | αι12 (3.0KW) | βι12 (1.8KW) | 1FK7063 (1.9KW) | |

| Coolant pump motor | 0.7KW (50Hz) / 1KW (60Hz) | ||||

| 18″STANDARD ACCESSORIES | 18″OPTIONAL ACCESSORIES |

|---|---|

| CNC controller: FANUC, FAGOR or SIEMENS | 3-Jaw Chuck |

| AC spindle motor | 4-Jaw Chuck |

| Auto lubrication system | Face Plate |

| Electric Cabinet Heat Exchanger | Hydraulic Power Chuck |

| Coolant system | Double Chuck System |

| 2-door Splash guard | Steady Rest |

| Work light | Follow Rest |

| Spindle sleeve and Tool centers | Milling Device |

| Leveling bolts & pads | Hydraulic Spindle Orientation |

| Tool box with oiler, spare fuse, paint & tools | Boring Device |

| Operation & service manual | Hydraulic 4-way Tool Post |

| Hydraulic V8 Turret | |

| Hydraulic Tailstock | |

| Chip Conveyor | |

| Electric Cabinet Air Conditioner | |

| Spindle Oil Cooler | |

| Full Guarding |