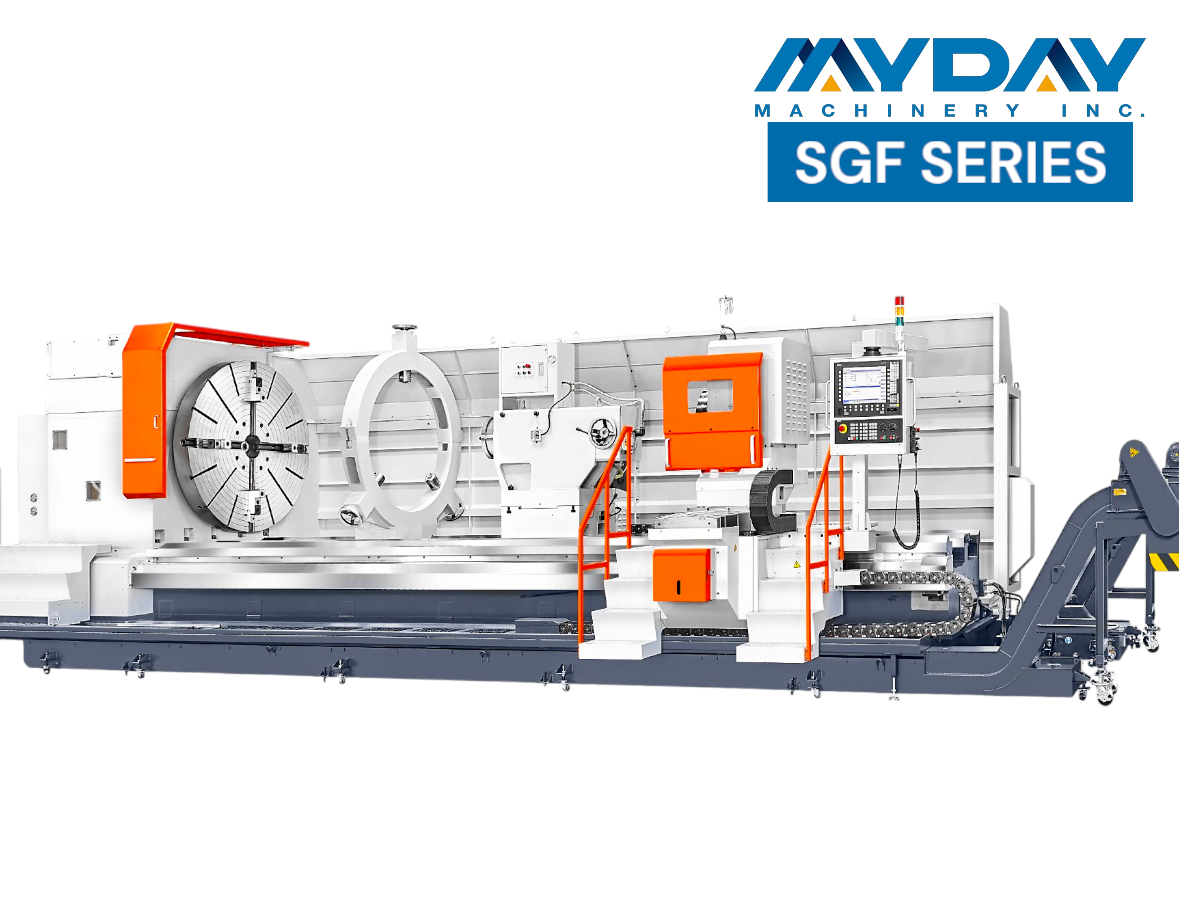

CNC Giant Four Guideway Lathe (52” Bed)

Thursday 27 March 2025

Supplier Information

MYDAY

Visit Website

Detailed Specification

CNC Giant Four Guideway Lathe is a special type of flat bed lathe. It has one wide bed and 2 pairs of guide ways. Its tailstock and steady rests are placed on the pair of guide ways at the rear side. Thus, we would build the carriage across the 4 guide ways (called full length cross slide) as standard model; this model could stand for very heavy duty machining and has full cross slide travel. Besides, we could build its carriage on one pair of guide way at the front side (called half length cross slide). In this option, the carriage wouldn’t interfere with steady rests and its tailstock; it’s very good at outer diameter machining at one time without removing steady rests.

| Description \ Model | SGF1800 | SGF2000 | SGF2250 | SGF2500 |

|---|---|---|---|---|

| Swing over bed | 1800 mm | 2000 mm | 2250 mm | 2500 mm |

| Swing over cross slide: Full length (opt.1) | 1240 mm | 1440 mm | 1690 mm | 1940 mm |

| Swing over cross slide: Half length (opt.2) | 1325 mm | 1510 mm | 1745 mm | 1985 mm |

| Center height | 900 mm | 1000 mm | 1125 mm | 1250 mm |

| Bed width | 1345mm (52.9”) (1575mm with auxiliary guideway) | |||

| Distance between centers | 3000 mm ~ 12000 mm | |||

| Travel of Full-length cross slide | X-axis: 1100mm, Z-axis: 2600~14600mm | |||

| Travel of Half-length cross slide | X-axis: 800mm, Z-axis: 3000~15000mm | |||

| Spindle bore / Spindle nose | Ø210mm / A2-15 or A2-20 | |||

| Spindle speeds (4 Steps) | 5 ~ 460 rpm (Chucks are NOT considered) | |||

| Spindle motor | FANUC 45KW, FAGOR 51KW, SIEMENS 51KW, or 100HP with inverter | |||

| Rapid travel | X-axis: 5 m / min , Z-axis: 5 m / min | |||

| Tailstock spindle travel / Quill | 300 mm / Ø290 mm (Rotary) | |||

| Tailstock spindle taper | MT#7 | |||

| Controller | FANUC 0i-TF | FAGOR 8055i4″ | SIEMENS 828D | |

| X-axis servo motor | α22i (4.0 KW) | FKM 66 (4.9 KW) | 1FK7103 (5.2 KW) | |

| Z-axis servo motor | α30i (7.0 KW) | FKM 82 (6.7 KW) | 1FK7105 (7.7 KW) | |

| X-axis transmission | Ball Screw Ø50mm with 1:2 gear set | |||

| Z-axis transmission | Ball Screw Ø80mm (BC 3~4M), Rack and Pinion (BC 5~15M) | |||

| Coolant pump motor | 0.7KW (50Hz) / 1KW (60Hz) | |||

| 52”Standard Accessories | 52”OPTIONAL ACCESSORIES |

|---|---|

| CNC controller: FANUC, FAGOR or SIEMENS | 4-jaw chuck |

| AC spindle motor | Face plate |

| Spindle oil cooler | Bull Nose Head(on Tailstock Quill) |

| Electric cabinet air conditioner | Steady rest(3point Closed Type) |

| Auto lubrication system | Steady rest(3point C- Type) |

| Coolant system | Steady rest(2-point Open Type) |

| Hydraulic 4-way toolpost or 8-station turret | Boring Device |

| Chuck guard and turret guard, control panel moving along with carriage | C-axis Control |

| Rear splash guard and chip conveyor (DBC≦8 meter) | Power Turret |

| Spindle sleeve and tool centers | Bigger Tailstock Rotary Quill |

| Motorized Tailstock with rotary quill | Bigger Rack and Dual Pinions for Extremely High Thrust on Z-axis |

| Leveling bolts & pads | |

| Tool box with oiler, spare fuse, paint & tools | |

| Operation & service manual |