831 Series Single

Thursday 12 February 2026

Supplier Information

Detailed Specification

831 Series Single by chiron

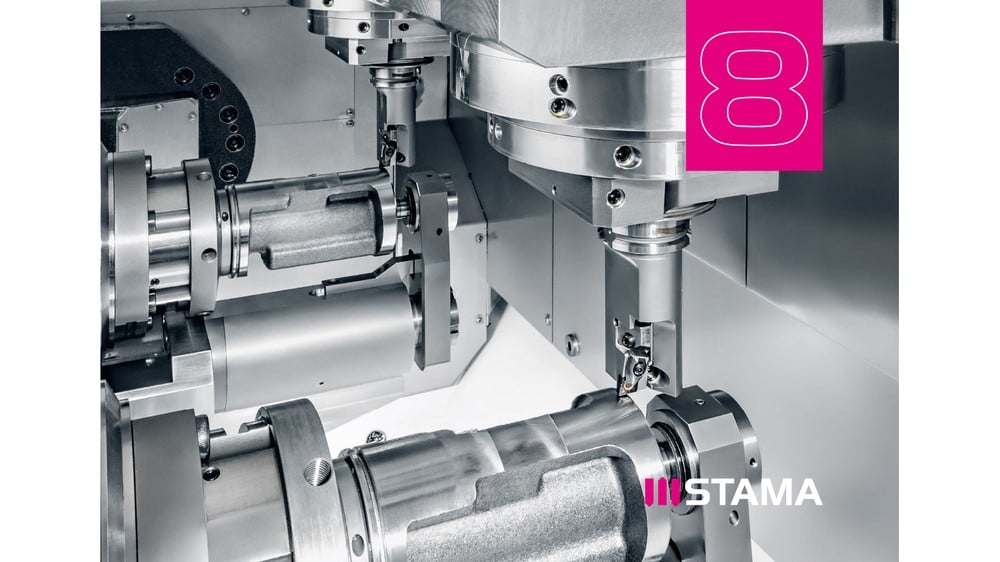

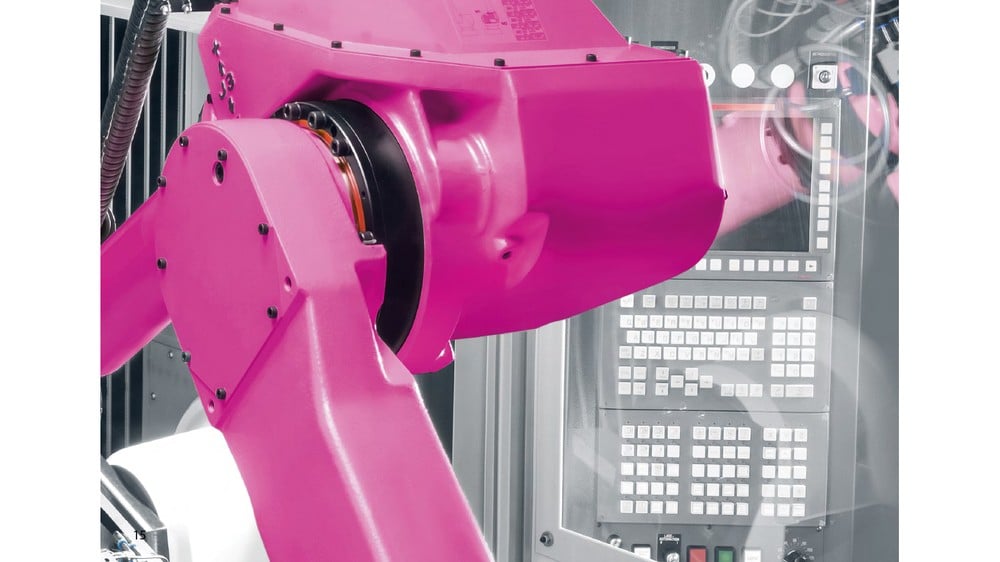

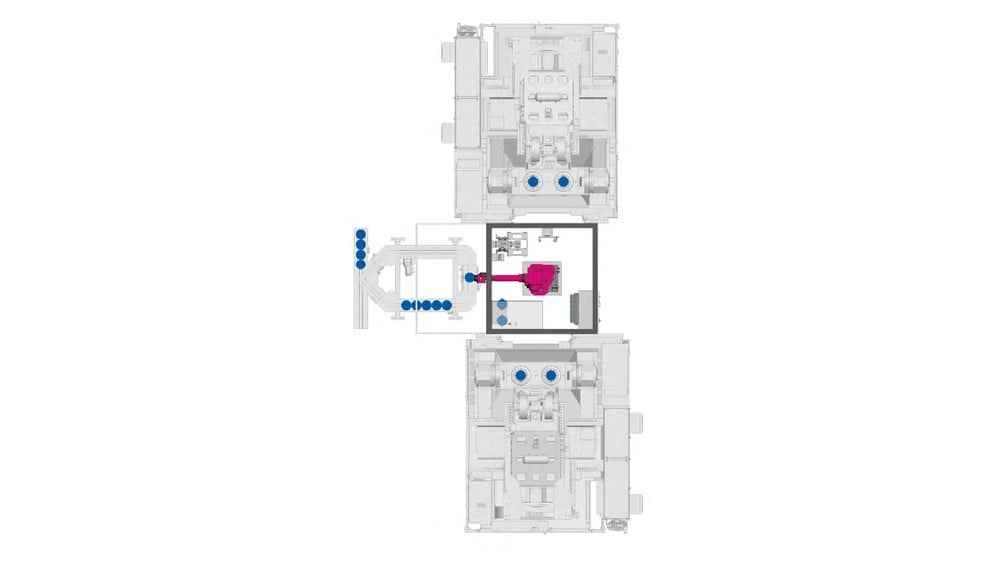

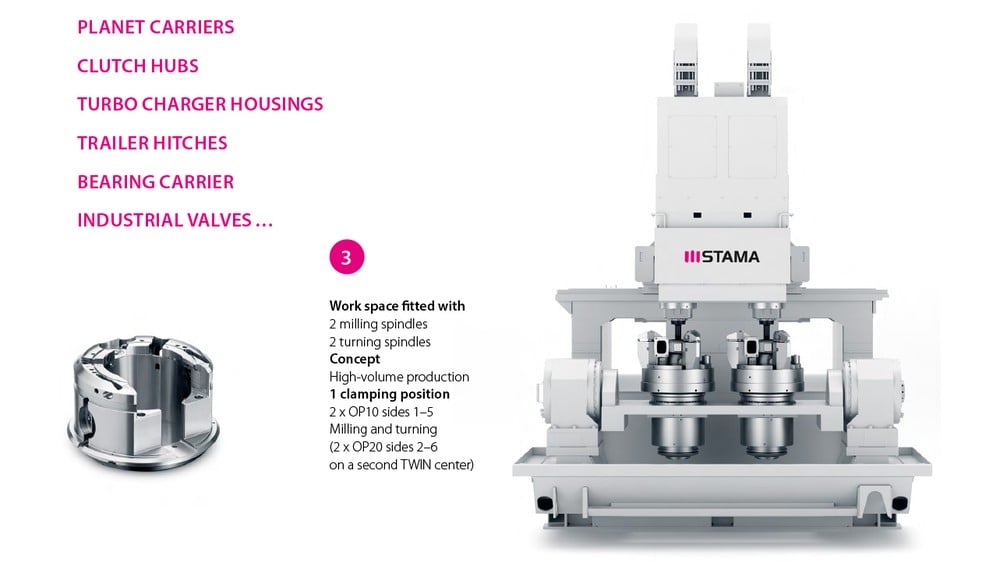

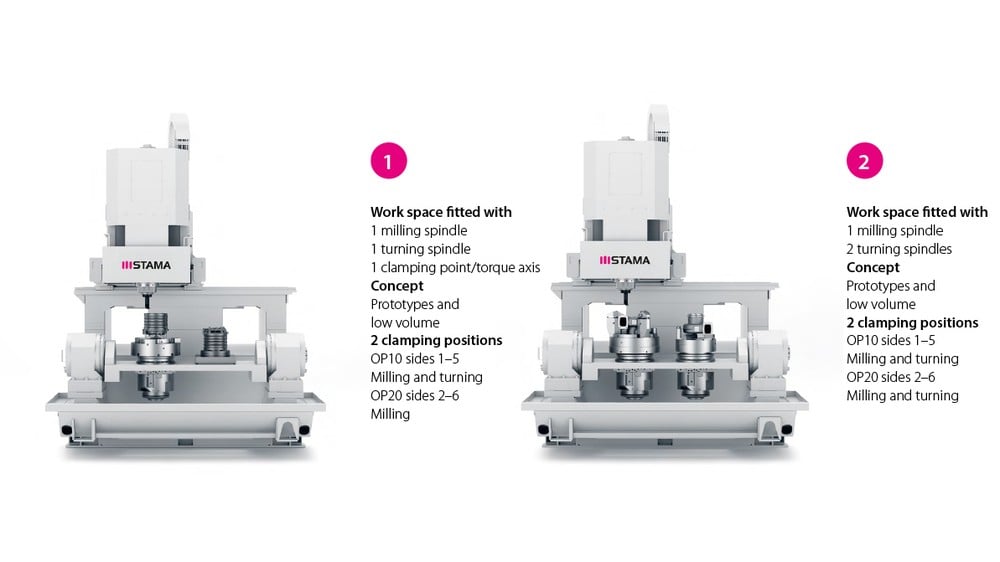

SYSTEM 8, MT-FLEXIBLE, TWIN-PRODUCTIVE, STAMA-DYNAMIC

IN LOW AND HIGH-VOLUME PRODUCTION

The focus here is on those workpieces that demand the use of the entire cutting range: Milling, drilling and turning.

Instead of splitting up the machining of high-quality components using the Taylorist approach, Stama committed to this idea in 2002: Making it technically feasible and possible to implement any component and cutting process innovation on just one machine. For both – low and high-volume production applications.

Today, Stama System 8 machines offer complete flexibility to optimally set up processes with powerful and precise milling, drilling and turning operations, specific for each component.

Stama is highly dynamic and fully flexible with MT, being twice as productive with TWIN.

PRECISELY COMBINED

COMPLETE MACHINING FLEXIBILITY EACH STEP OF THE WAY FOR YOUR PRODUCT AND PROCESS INNOVATIONS

There are good reasons to split up a milling-turning process: Quantity, cycle time, exacting surface quality and precision. However, these arguments may also support an approach that does not divide the process based on cutters that are rotating and stationary. Instead co-ordinating it on the basis of the optimum sequencing of milling, turning and drilling operations. This is a significant advantage if the geometric dimensioning and tolerancing of a subsequent machining step have to be a complete match with a highly precise reference point. There are components in a wide range of industries, which, considering a variety of aspects, preferably should not be manufactured in separate processes on multiple machines reserved for specialised tasks. For these precise, complex workpieces, System 8 milling-turning centres offer full milling and turning power combined with high dynamics and precision – all on a single machine.

This means complete process set-up and optimization flexibility, for even more precision.

MC‘S AT FULL SPIN

4TH AND 5TH AXIS TORQUE DRIVES ARE STATE-OF-THE-ART, SYSTEM 8 OFFERS FULL TURNING POWER

What a turning machine lacks in terms of powerful milling performance, applies vice-versa to milling machines: The milling performance of driven tools is less powerful and torque drives do not attain the rotational speeds and rigidity of full-fledged turning spindles. System 8 centres combine the full performance scope of both cutting technologies. Another benefit: Fast set-up/re-tooling. Stama’s TWIN technology delivers a high level of surface area productivity.

Complex and precise components up to Ø 600 mm are clamped into the swivelling turning spindles in a gravitation oriented manner. Single or twin-spindle all 5-axis machining options can be achieved in every clamping position – while achieving full milling and turning performance in HSK-A63 and HSK-A100.

Technology information

|

Performance |

Variable |

Single |

|

Spindle distance |

mm |

– |

|

Milling spindle(s) |

kW |

22/51 |

|

Torque |

Nm |

140/170 |

|

Spindle speeds |

x 1000 r.p.m. |

10/12/15* |

|

Turning spindle(s) |

kW |

43 |

|

Torque |

Nm |

180 |

|

Spindle speeds |

x 1000 r.p.m. |

4.2 |

|

Tools |

|

|

|

HSK-A63 |

Places |

70 |

|

Weight |

kg |

5/10 |

|

Diameter |

mm |

88/140 |

|

Length |

mm |

300 |

|

Chip-to-chip time |

s |

2.9 |

|

Traverse paths |

|

|

|

X-axis |

mm |

780 |

|

Y-axis |

mm |

400 |

|

Z-axis |

mm |

400 |

|

Rapid motion |

m/min |

75 |

|

Acceleration |

g |

up to 1.8 |

|

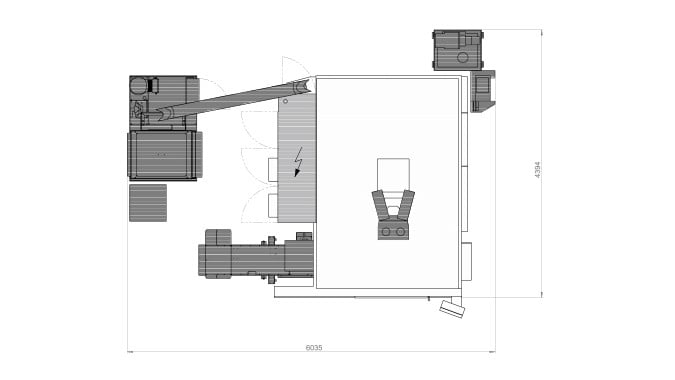

Dimension/weight |

|

|

|

Width |

mm |

3330 |

|

Depth |

mm |

3650 |

|

Height |

mm |

3240 |

|

Weight |

kg |

7500 |