DC12iMT

Wednesday 11 February 2026

Supplier Information

Detailed Specification

DC12iMT by axile

The DC12iMT is the most robust VMC in AXILE’s arsenal, perfectly suited for handling larger, lengthy workpieces. With a 1200 mm diameter built-in table and 2.5 tonnes maximum weight capacity, the DC12iMT is able to accommodate large and heavy 5ax components, while the 2,200 x 1,200 mm machine bed will take on board long and complex parts common in the aerospace, power generation, and die and mould industries. Its double-column bridge construction allows for greater rigidity, as well as greater control over thermal deformation. As a result, the DC12iMT is capable of deep cuts and complex contouring while maintaining utmost precision.

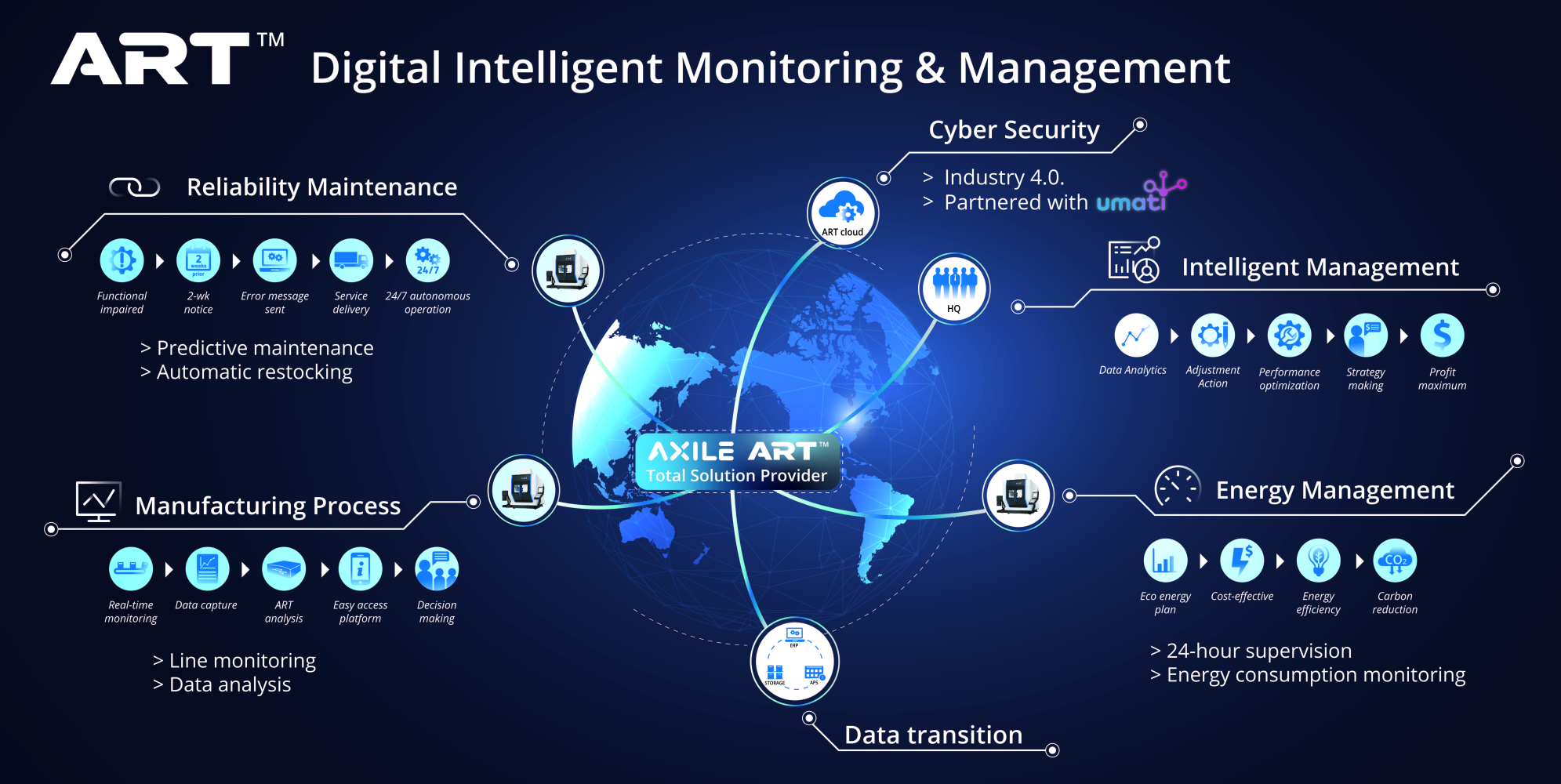

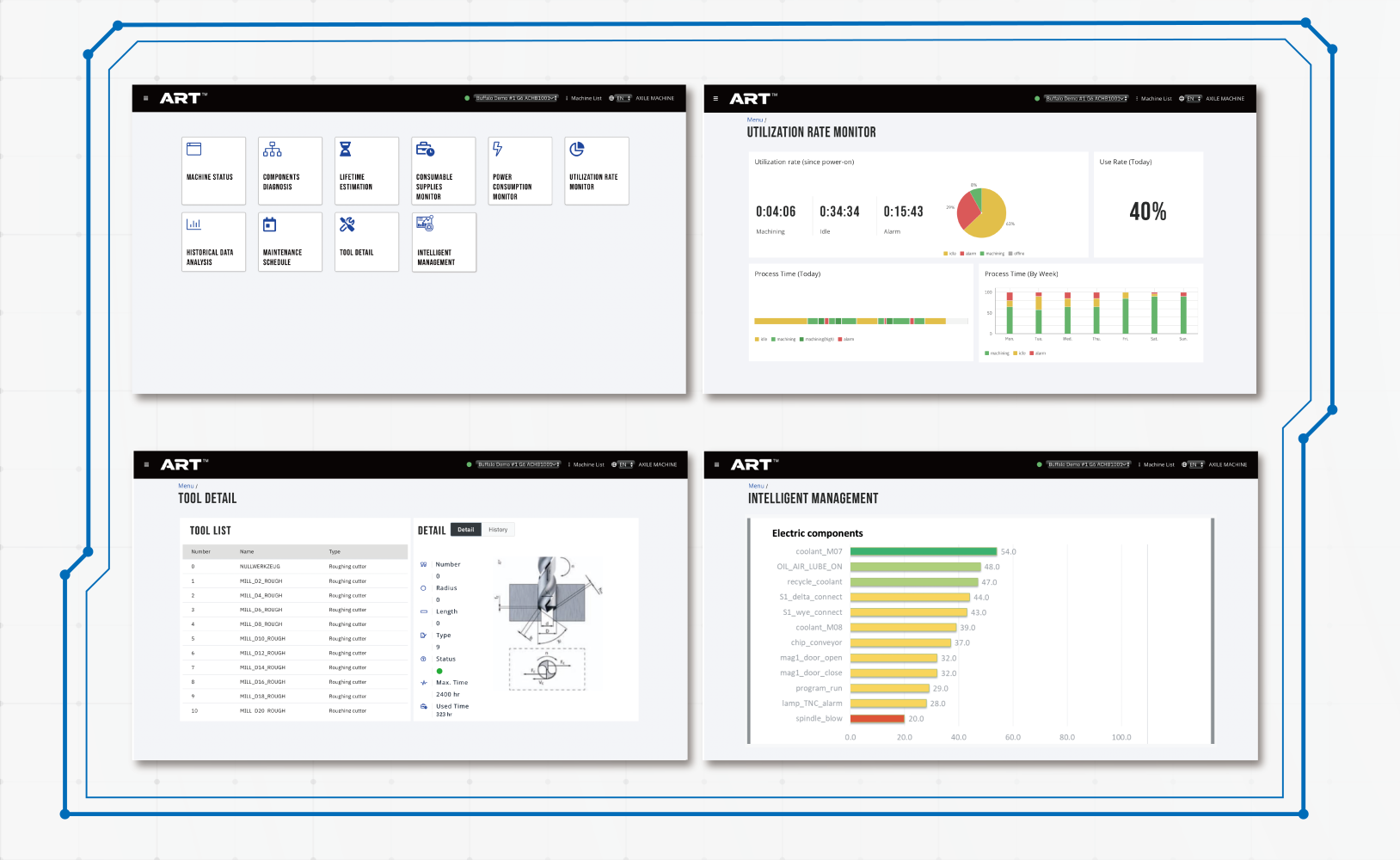

The DC12iMT is equipped with the ART™ intelligent monitoring system (hardware & software). Which enables the adoption of automation and optimises manufacturing productivity through real-time machining data, achieving sustainability in all aspects of business operations.

A snapshot of the AXILE DC12iMT:

-

Combines both milling and turning in one machine, greatly increasing operational flexibility

- By reducing set-up times and potential clamping errors, the DC12MT can efficiently machine a wider variety of parts, especially cylindrical components

-

Laser measurement updated for turning tool applications

-

ART™ monitoring system (hardware & software)

-

Massive bridge supported on a one-piece base casting

-

Machine body made of high-quality cast iron

-

3-guided Y-axis carriage to ensure speed and stability

-

Extremely rigid 4-guided Z-axis Box-in-Box designed RAM

-

Torque motor driven B (spindle) and C (table) axis

-

Large tool magazines as standard

-

Various pallet changer solutions as option

Technology information

|

MODEL |

|

UNIT |

DC12iMT |

|

STANDARD LINEAR AXES |

X axis |

mm |

2200 |

|

Y axis |

mm |

1400 |

|

|

Z axis |

mm |

1000 |

|

|

STANDARD ROTARY AXIS |

Built-in rotary table diameter |

mm |

Ø 1200 |

|

Full machine table |

mm |

2200 x 1200 |

|

|

Table load |

kg |

2500 |

|

|

B axis driven system (spindle head) |

Swivel +/- 110° |

Torque motor |

|

|

C axis driven system (rotary table) |

Rotary 360° |

Torque motor |

|

|

STANDARD |

Maximum Feedrate |

m/min |

36 |

|

Lubrication type |

|

Grease |

|

|

STANDARD SPINDLE |

Driven system |

|

Built in |

|

Maximum speed |

rpm |

20,000 |

|

|

Power S1/S6 (40%) |

kW |

60/73.1 |

|

|

Torque S1/S6 (40%) |

Nm |

119.4/145.4 |

|

|

Interface |

|

HSK-T63 or HSK-T100 as an option |

|

|

Bearing lubricant |

|

Oil air |

|

|

Water chiller ±0.2 degree |

|

STD |

|

|

STANDARD |

Magazine capacity STD |

Tools |

90 |

|

Smart tool load station |

|

STD |

|

|

ROTARY TABLE |

Maximum table rotation speed |

rpm |

800 |

|

Power |

kW |

S1 40.8 |

|

|

Torque |

|

S1 3000 Nm, S6-40% 3960 N |