The Winning Combination: New CoroMill® Face & Shoulder Milling Cutters

In a competitive manufacturing environment, performance, cost efficiency, and sustainability are essential. CoroMill® milling solutions set the benchmark, delivering reliable results from roughing to finishing across all materials—especially ISO P, M, S, and K.

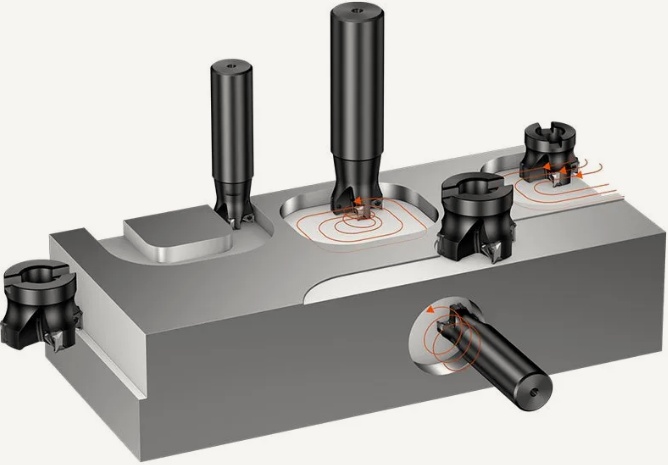

Introducing the latest face and shoulder milling innovations: CoroMill® MS20, MS40, and MS60.

CoroMill® MS20 – Precision 90° shoulders

Evolving from the proven CoroMill® 390, MS20 is the first choice for accurate 90° shoulders. It offers excellent dimensional control, reliable chip handling, and high versatility across multiple operations—reducing tool inventory and overall consumption.

CoroMill® MS40 & MS60 – The perfect complement to CoroMill® 490

While CoroMill® 490 remains the universal shoulder milling solution, MS40 and MS60 deliver added performance when demands increase.

- MS40 is optimized for repeated passes and wall machining, offering high rigidity, predictable tool life, and four cutting edges per insert for stable, high-efficiency machining.

- MS60 is ideal for roughing and semi-finishing, with six cutting edges and a reversible triangular insert design that lowers cost per edge and improves material efficiency.

CoroPlus® ToolGuide – More than cutting data

CoroPlus® ToolGuide helps you quickly select the right solution with validated cutting conditions and environmental impact insights, including power consumption and CO₂ emissions.

Performance you can rely on

With CoroMill® MS20, MS40, and MS60, supported by CoroPlus® ToolGuide, you gain higher productivity, lower costs, and reduced environmental impact. Sustainable performance starts here.