In injection molding, safeguarding mold integrity is paramount. Enter KePlast’s Automatic Ramp Calibration, a game-changer. This feature, integral to the KePlast Software, identifies the optimal moments for mold opening and closing, ensuring smooth operations and prolonging mold life.

Mold damage poses significant challenges for plastic manufacturers, leading to production setbacks, defective parts, and increased maintenance costs. Traditionally, calibrating machines post-mold exchange demands extensive time and expertise, a hurdle exacerbated by labor shortages.

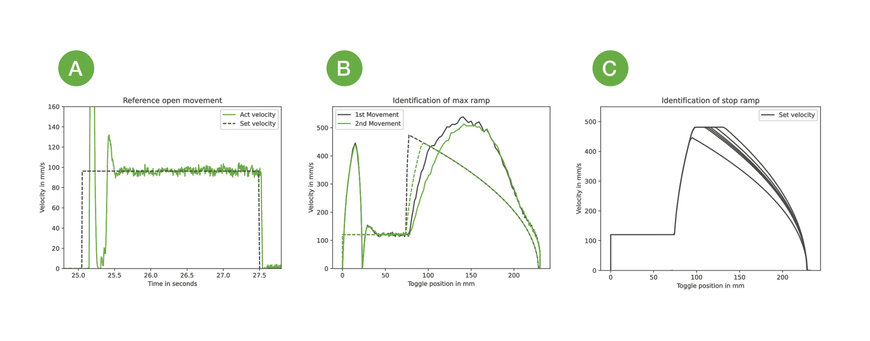

KePlast’s Automatic Ramp Calibration simplifies this process, automatically determining the ideal speed and acceleration for mold movements. Analogous to parking a car, it ensures smooth, controlled movements, akin to the finesse of a seasoned driver.

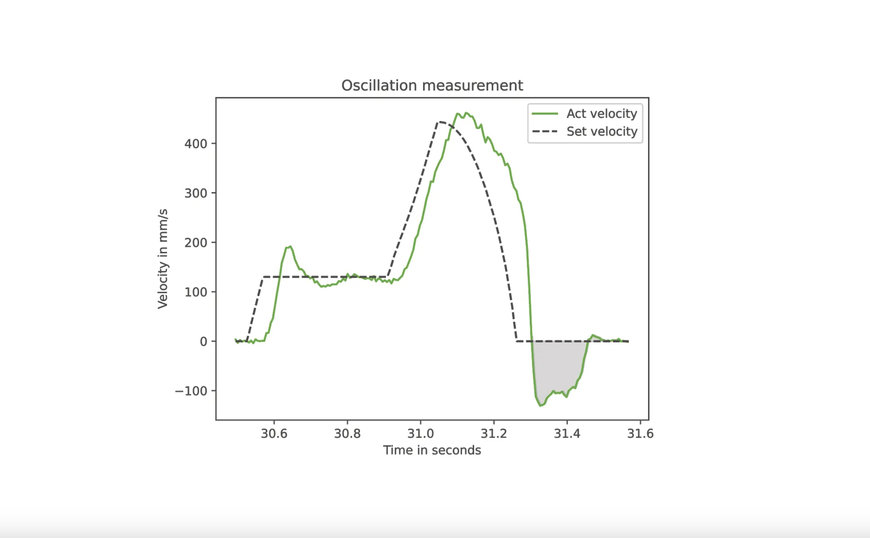

The injection molding process involves multiple velocity stages, each demanding precise control to prevent mold damage. KePlast’s algorithm, adeptly handling these complexities, adjusts velocity and acceleration parameters to minimize oscillation and maximize efficiency.

Even without active brake control mechanisms, KePlast’s Auto Calibration feature delivers impeccable results, making it ideal for standard or low-end machines.

By evaluating oscillation and fine-tuning parameters, KePlast’s Auto Ramp Calibration optimizes braking, ensuring smoother movements and prolonged mold life. This innovative solution streamlines operations, reduces reliance on experts, and enhances machine efficiency across hydraulic machine types.

Unlock the potential of your injection molding process with KePlast’s Automatic Ramp Calibration – the key to smoother operations, longer mold life, and heightened efficiency.

For more insights, download KEBA’s whitepaper “Faster & more accurate control technology with KEBA concepts & KePlast Smart Functions” at www.keba.com.

Original source Metal Working Mag