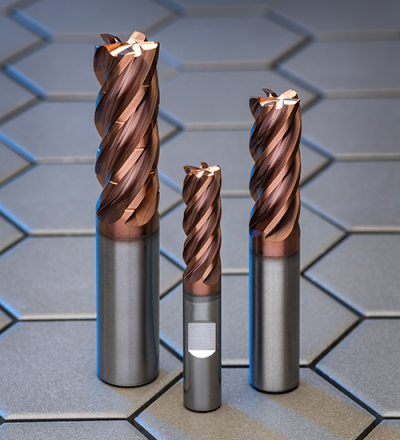

IMCO Introduces POW•R•FEED M935 Five-Flute Endmills with Revolutionary Grinding Technology

By Ashutosh Arora

IMCO Carbide Tool has unveiled its latest innovation in high-performance cutting tools, the POW•R•FEED M935 five-flute endmills, designed to push the boundaries of machining efficiency. At the core of this new tool is IMCO’s proprietary multi-parabolic grinding (MPG) process, a breakthrough in tool design that enables unprecedented levels of metal removal while delivering freer cutting action across a wide range of materials, including mild steels, stainless steels, and titanium.

The M935 series was created in response to the growing demands of manufacturers who require tools that can handle increasingly complex geometries and more aggressive tool paths without sacrificing durability or precision. Traditional grinding methods often limit tool geometry, constraining performance when it comes to cutting speed, stability, and chip evacuation. With MPG, IMCO has overcome these limitations by introducing end face, flute, and core geometries that were previously difficult—if not impossible—to achieve with conventional grinding technology.

The result is a tool that makes highly aggressive machining strategies possible, even when dealing with complex multi-axis movements. This opens the door for faster roughing operations, smoother finishing, and optimized chip control in some of the most challenging materials used in modern engineering. In particular, stainless steels and titanium alloys are known for their toughness and poor thermal conductivity, often leading to excessive tool wear, chatter, and shortened tool life. The M935 tackles these challenges head-on, combining robust edge strength with free-cutting geometries that reduce heat generation and minimize cutting forces.

IMCO emphasizes that the POW•R•FEED M935 is not just about incremental improvement but represents a step-change in endmill design. The MPG process introduces unique parabolic curves along the flute profile, allowing for enhanced chip evacuation and reduced cutting resistance. By controlling chip flow more efficiently, the tool not only achieves higher metal removal rates but also improves surface quality, extending tool life and enabling longer uninterrupted cutting cycles. For manufacturers, this translates into increased productivity, fewer tool changes, and ultimately lower costs per part.

Another critical advantage of the M935 lies in its versatility. While optimized for high-efficiency machining of steels and titanium, its design also delivers impressive results in softer materials. This flexibility makes it an ideal choice for job shops and production facilities that must switch between different materials without compromising on performance. In addition, the five-flute configuration strikes a balance between high feed rates and stability, offering users a tool that performs exceptionally well in both roughing and finishing operations.

By introducing the M935, IMCO continues its long-standing mission of delivering innovative, application-driven solutions to the machining industry. The company highlights that its development process involved extensive real-world testing, ensuring the tool performs reliably in diverse production environments. The combination of groundbreaking design, robust performance, and consistent results underscores IMCO’s reputation for pushing the limits of carbide tool technology.

As industries such as aerospace, medical, and precision engineering demand ever more efficient and reliable cutting tools, the POW•R•FEED M935 arrives at the right moment. Its unique grinding process and advanced geometry give manufacturers the confidence to pursue aggressive machining strategies without the drawbacks traditionally associated with such approaches. For those looking to maximize productivity while maintaining tool life and part quality, IMCO’s latest five-flute endmill promises to be a game-changer.