VOLLMER has now launched its new VGrind 360S grinding machine for the machining of carbide tools. As a complete machining solution for rotationally symmetric solid carbide tools, the new VGrind 360S is suitable for manufacturing cutting tools for all industry sectors.

This new 5-axis CNC grinding machine can be used to machine carbide tools with a diameter up to 25.4mm and depending on the machine kinematics and the equipping of the grinding wheel packages, it can even be used for tools up to 150mm diameter. The VGrind 360S incorporates wear-free linear induction motors on the X, Y and Z-axes to lower maintenance costs for the machine whilst demonstrating higher surface quality for the tool and improved precision.

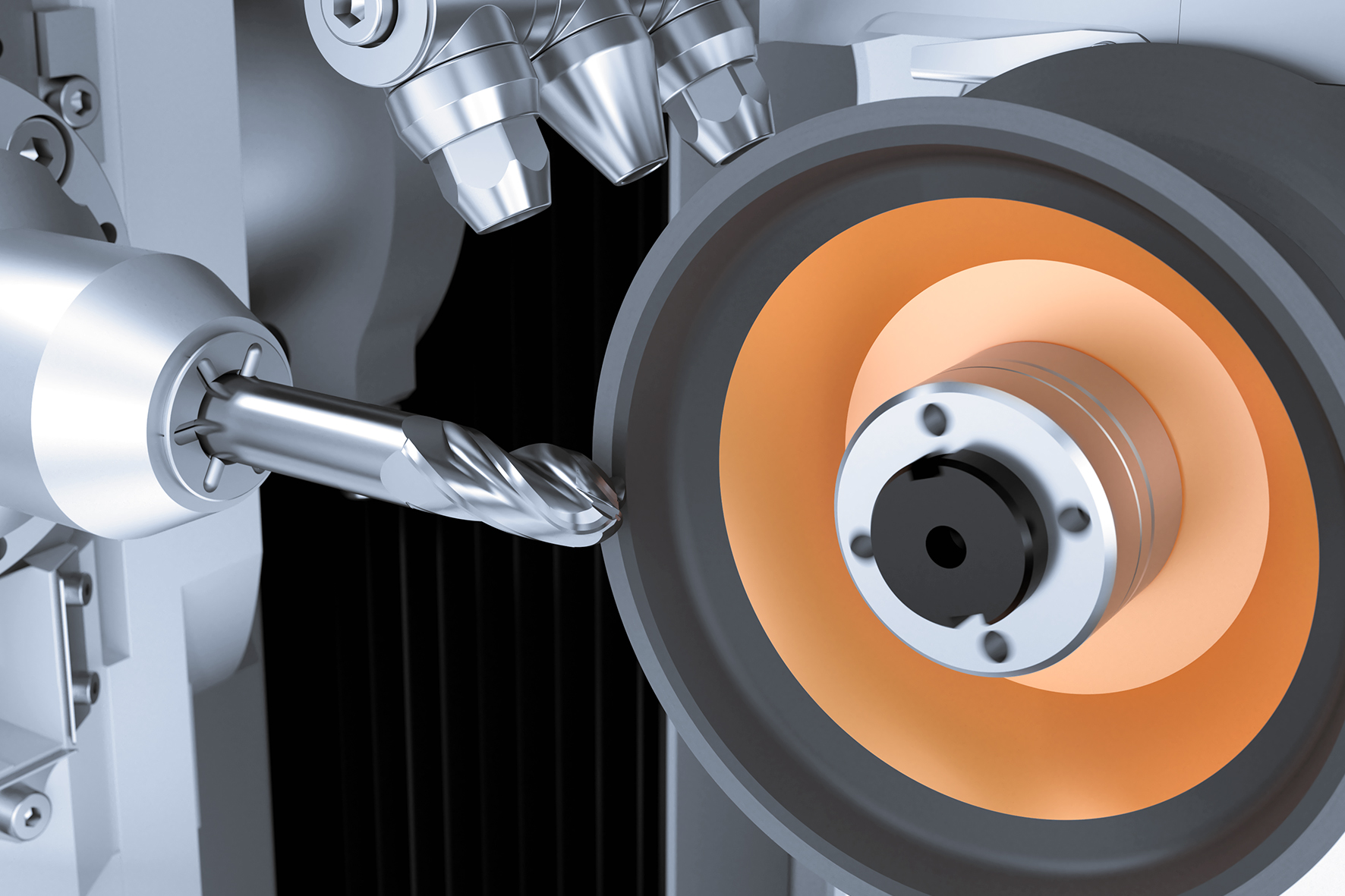

The tried-and-tested vertical double-spindle concept from VOLLMER now features an oriented spindle-stop for the first time. Also known as spindle indexing, this always stops the spindle at a specific position and the result is a reduction of axial run-out errors and concentricity issues whilst off-setting wear in the HSK holding system. Another new feature is a heat plate exchanger to efficiently cool the motors and spindles, which in turn leads to increased thermal stability and logevity. Furthermore, this effective cooling concept that has now been optimised and extended demonstrates absolute perfect precision when processing tools to the tightest of geometric tolerances.

The VGrind 360S incorporates VOLLMER’s trusted operating concept and can be operated unmanned around the clock thanks to automation features such as a pallet magazine, free-arm robot or chain magazine. The options for automation include the HP160 pallet magazine for up to 900 tools with a double gripper to guarantee fast changeovers, the HPR 250 free-arm robot for the automatic machining of tools with various shaft diameters and the HC 4 chain magazine that has space for 39 HSK-63A tools or up to 158 shank-type tools. This automation also extends to the 8-tool grinding wheel changer that ensures you always supply the right grinding wheel for the job at hand with no manual intervention. As an option, coolant nozzles can be automatically exchanged with the wheel sets on both spindles.