LK implants CMM Technology at Ortho Baltic

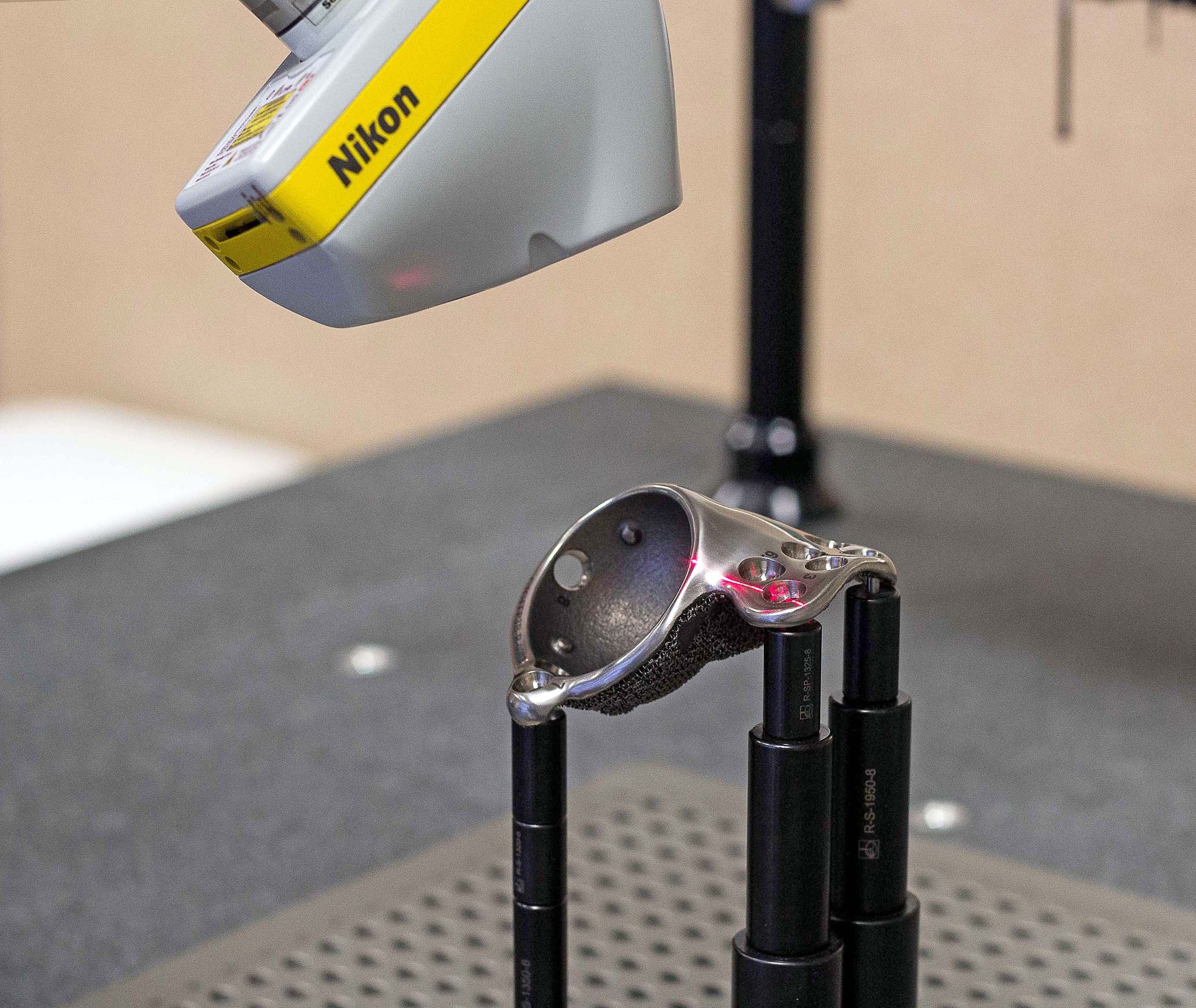

Quality assurance is vital in the production of accurate, patient-specific implants, endoprostheses and surgical guides. Consequently, Ortho Baltic in Kaunas, Lithuania has installed an ALTERA multi-sensor coordinate measuring machine (CMM) from British manufacturer, LK Metrology. The CMM has been fitted with a Nikon LC15Dx laser scanner for fast inspection of 3D-printed implant surfaces and screw holes.

Paulius Lukševičius, Engineer of Mechanics at Ortho Baltic explained: “3D printing is a complicated technology and there is a big variation in parameters, so predicting the accuracy and geometry of such additively manufactured objects is quite a challenge.”

“Patient-specific implants are a bespoke treatment solution, which means that the surgery must be pre-planned virtually, so the implant can simply be put in place. To be able to execute the virtual plan, it is vital to be 100% sure that implant geometry is the same as the CAD model and that the holes are machined to high accuracy.”

“To fulfil these goals, we use a variety of metrology equipment. The LK CMM with laser scanner is irreplaceable when we need to perform fast checks after each manufacturing and post-processing stage, especially to check spherical surfaces, bearing surfaces and hole angles.”

Unlike standard modular hip implants used to treat severe clinical conditions, patient-specific alternatives are designed as a single device with anatomically adapted surfaces. The production route eliminates the risk of instability and adapts the implant to the bone rather than the bone to the implant. A major benefit of the procedure is that during surgery, there is no need to shape the bone or use bone cement, meshes and augments.

For manufacturing the implants, Ortho Baltic uses direct metal laser sintering equipment purchased in 2012. After 3D printing, implants undergo a variety of post-processing steps including heat treatment, surface polishing and thread milling of holes. There are several medical device standards and regulations that must be met, which is why it is paramount for products to be of ultra-high accuracy.

With fine tolerances and strict standards to be adhered to, the post-processing stages are repeated until the physical implant exactly matches the desired virtual model. Quality assurance measures are undertaken using the LK CMM following every step, during which the laser scanner can show quickly how well the physical part matches the virtual model.

Mr Jokymaitytè said: “The CMM with laser scanner is very effective for inspecting features and surfaces of bigger parts such as an acetabular implant, for quality control of standard products like osteosynthesis plates and for assessing standard elements in patient-specific implants, eg threaded holes and spherical shapes.”

As the Quality Control Laboratory at Kaunas was a new project to supplement the additive manufacturing facilities, there were no previous systems to be replaced. Ortho Baltic knew what was required and compared the best technologies on the market to find the right solution.

Mr Lukševičius commented: “The primary requirement was to have the capability to inspect parts made from different types of materials. The size of the CMM’s working area was also important, but most crucial was accuracy.”

He pointed out that a key advantage of the laser scanner is its ability to tackle reflective and multi-material surfaces. It maintains accuracy, speed and data integrity by intelligently and continuously adapting the laser settings for each measured point. Probing error is comparable to that of tactile inspection (1.9μm) and data collection is fast at 70,000 points per second. By maintaining such high standards when scanning difficult surfaces, the unit is an ideal tool for the quality evaluation of complex parts in the medical industry.

Mr Lukševičius concluded: “The LK solution offers us more in-depth knowledge of what we are manufacturing and gives better precision and understanding of 3D printing errors and deviations. It means we achieve superior products and avoid problems during production. Implants with LK quality assurance are more reliable and it is easier to prove their worth.”

“Often our quality control laboratory receives inquiries from other manufacturers in the medical sector and from different industries to perform subcontract geometrical inspection for them.”