MPS Micro Precision Systems AG (MPS) uses grinding for demanding high-precision components to IT02 tolerances. With a total of seven Studer grinding maachines, it has cylindrical grinding expertise in the medical and orthopaedics, science and optics sectors. Thanks to automation, series runs are flexibly produced unmanned 24/7, bringing prototypes to market faster.

With more than 400 staff MPS was formed from RMB (Roulements Miniatures Bienne SA), a company formed in 1969 that developed components for the Apollo space mission. With 250 employees, Biel is the MPS Group’s largest site and has more than 140 turning, milling, grinding, polishing and eroding machines.

Consistent investments in grinding machines

Michael Bazzan, the MPS Production Manager says: “With Studer grinding machines, we have high capacity for producing precision components. The grinding is matched to our varying size spectrum, which ranges from individual component production up to 25,000 pieces per year for some customers.”

Three of the seven Studer machines are equipped with automatic loading. The focus is on the Studer S33 for recirculating ball screws and a Studer S21 flexible production cell (Flex Cell).

Didier Noirjean, Flex Cell Manager: “The cell was integrated into cylindrical grinding as a self-sufficient production unit to grind prototypes and new developments without intervening in production. With this cell, development to a finished part is quicker. The Studer S21 can be changed over quickly and configured for different parts.”

While the Flex Cell involves prototypes, series parts are machined on the other six Studers. These include recirculating ball screws from 0.8mm diameter. All components are developed and manufactured in-house. The larger screw spindles with gothic-arch thread are produced on an automated Studer S33. M. Nercide says: “We are involved in R&D with these precision screw spindles. The expertise developed by MPS in the precise positioning of lens groups enables the company to offer powerful alignment systems for optical components such as zoom and laser beam systems.”

MPS Microsystems miniature recirculating ball screws are made from stainless steel and are positioned with double nuts that enable fine axial adjustment. The customised spindles guarantee smooth movement thanks to the high precision ground thread.

The gothic-arch thread form is ground directly from solid hardened blanks. A macro was developed for these gothic-arch thread forms together with Studer. The grinding parameters can be adapted quickly to the respective screw spindles.

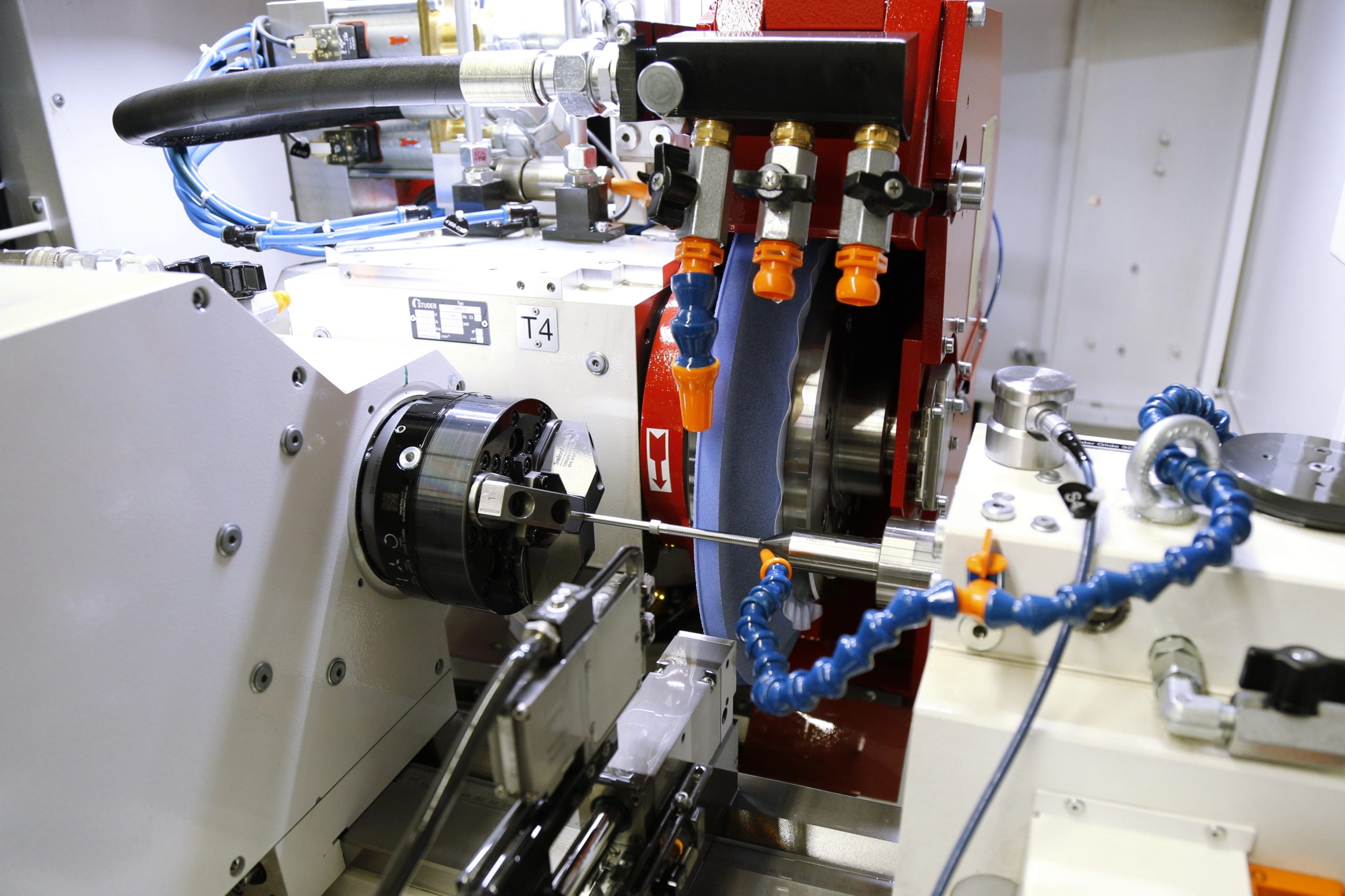

Mr Weyermann, the Regional Manager at Fritz Studer AG adds: “The Studer S33 is a cylindrical machine with a turret wheel head. The wheel head has two external grinding wheels, one for thread profiling and one for external grinding.”

To produce the medium-sized series cost-effectively, Humard developed a flexible handling system for automatic loading and unloading of workpieces in collaboration with MPS and Studer.

The Studer S33 requires 15 minutes to machine a screw spindle 8mm in diameter and 120mm in length. The thread is roughed and finished with the same grinding wheel. The grinding wheel is dressed repeatedly in the micron range throughout the grinding process. More than 1000 screw spindles of this size can thus be ground with one grinding wheel. The dressing process performs an important function during grinding. On one hand, the dimension and form are calibrated, and on the other hand, the cutting ability of the grinding wheel is defined. Both a diamond and a dressing roll are used for dressing.

Finally, Manuel Nercide takes a look at the past: “Seven years ago we made between 2000 and 5000 spindles, today we produce 50,000 spindles a year. We have continually reduced our production costs, not least thanks to investing in modern grinding machines. Seven years ago our production was four times as expensive. From this perspective, investments in modern production equipment are crucial for ensuring long-term viability.”