🎧Transforming production with Ceratizit UK & Ireland Ltd

Located in Westbury, Wiltshire, Atkinson Equipment began as a family business developing oil heating, refuelling and liquid transfer equipment and has evolved into a sophisticated operation serving multiple demanding sectors. Today, the company operates as both an OEM of pump systems and a JOSCAR-registered subcontract machining specialist serving defence, aerospace, automotive, rail, fitness and medical industries.

With 20 years at the company, Ben Hale, Engineering Production Manager at Atkinson Equipment has witnessed much of this evolution. Ben and his team understand the daily technical challenges that influence strategic decisions about tooling partnerships that can genuinely impact the bottom line.

The machine shop represents a significant investment in cutting-edge technology. The facility houses a range of Doosan, CMZ and Citizen turning centres. The milling department is equally impressive, featuring Brother 5-axis automated machining centres. This diversity enables Atkinson to tackle everything from bespoke pump components to high-volume production runs.

The Foundation of Trust

Several years ago, Atkinson Equipment needed special end mills for reaching beyond 130mm. Their existing distribution supplier didn’t have a solution. Ceratizit was approached and responded with a solid carbide end mill featuring dedicated aluminium geometry and, crucially, a necked design that delivered both the reach and the rigidity for stable machining. The tool completed the project swiftly whilst maintaining the demanding surface finish required.

“That single tool made an enormous difference to us,” recalls Ben Hale. “It wasn’t just about solving the immediate problem. What really impressed us was how Ceratizit’s technical team understood what we needed and delivered a special tool immediately.”

The Catalyst for Change

In February 2025, Atkinson Equipment took delivery of a Citizen L32-VIII LFV sliding head turning centre, a significant investment driven by a contract to manufacture gym equipment. The acquisition was primarily for a four-component project, each part was required in quantities of 30,000, totalling 120,000 parts.

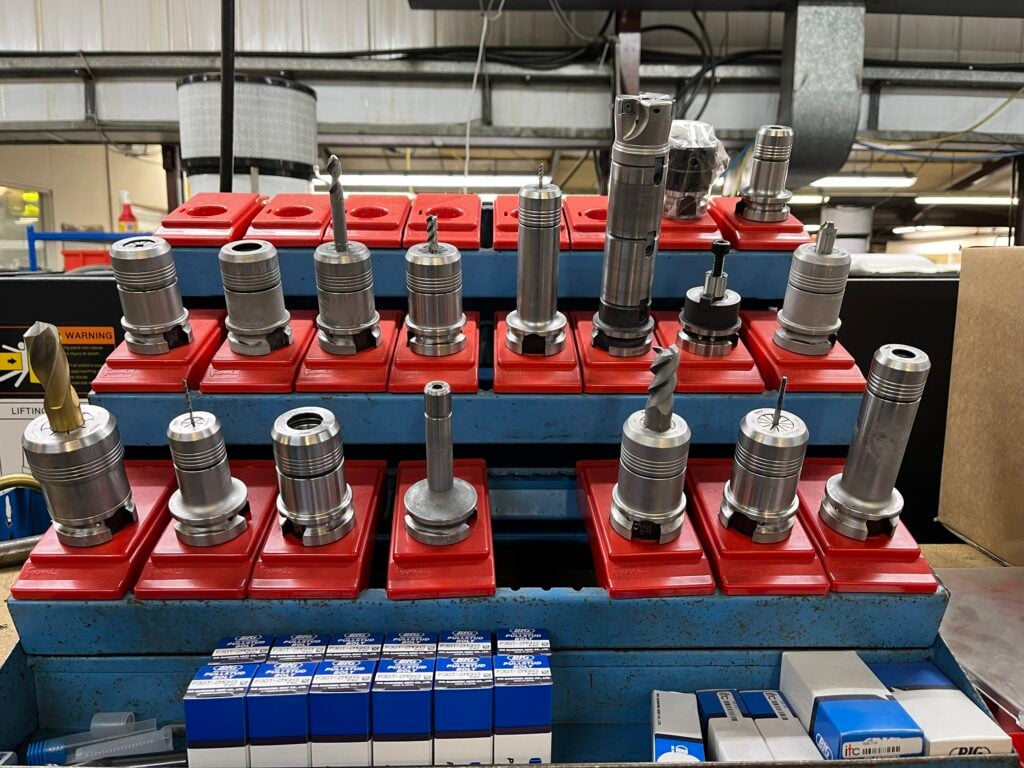

To streamline the supply chain, Atkinson Equipment wanted a single-source tooling solution for the new Citizen machine. The RFQ went beyond cutting tools. The ISO: 9001:2015 certified company needed collets, bushes, sleeves, tool holders, drills, and peripheral equipment to create a seamless transition into production. Once again, the OFTEC-approved company approached Ceratizit.

Iain Tattersall, Ceratizit UK & Ireland Technical Sales Engineer, who had previously supplied Atkinson Equipment, relished the opportunity. Working closely, the team developed a complete tooling package tailored to the components while maintaining the flexibility to support any future tooling requirements.

“What Ceratizit delivered went far beyond just cutting tools,” explains Ben Hale. “The breadth of products was impressive, but wha set them apart was the technical knowledge and support. The Ceratizit team were actively involved in maximising productivity and delivering prolonged tool life to optimise machine performance.”

The tooling package included everything from workholding to the latest generation cutting tools from Ceratizit’s performance range. Standard products were specified where appropriate, but the real value lay in the technical support. “The Ceratizit team optimised speeds, feeds, and cutting strategies and continually refined the process.”

Expanding the Partnership

The Citizen L32-VIII arrival established a foundation for a much deeper relationship with Ceratizit invited to conduct a comprehensive tooling review. Ceratizit systematically evaluated existing inventory, identified opportunities to swap out standard products for equivalent or superior alternatives from its own catalogue. This exchange reduced cutting tool costs whilst improving tool life by up to 20% on most product lines while improving productivity by up to 50% in some instances.

“The difference between working with a distributor and working with Ceratizit became crystal clear,” notes Ben Hale. “Ceratizit engineers know their products intimately. They can tell you what will work best for your specific application.”

One notable example involved replacing an older generation 17mm diameter U-drill with Ceratizit’s Pentrum drill. The upgrade delivered 40% cycle time reductions and extended tool life by more than 30%, which eliminated unplanned tool changes during production runs. Similarly, a turning insert upgrade on the Citizen resulted in improved cycle times and more critically surface finishes.

Iain Tattersall now visits Atkinson Equipment every two to three weeks, reflecting the active partnership. Rather than just taking orders, he works with machinists to identify challenges. “Having Iain and Vinny on the shop floor regularly makes a real difference,” emphasises Ben Hale.

Building for the Future

Atkinson Equipment’s tooling review success prompts discussions with Ceratizit on installing a TOM 80 tool vending system, aiming to transform storage, tracking, and replenishment. The TOM 80 offers 60 tool positions with the flexibility to add extensions as requirements grow. More importantly, it provides 24-hour access for machinists whilst automatically managing inventory levels and triggering replenishment orders. Every tool withdrawal is tracked by user, machine, and job, creating visibility into consumption patterns.

“The vending machine concept represents a major evolution in how we manage cutting tools,” explains Ben Hale. “Our previous supplier visited periodically with a printed spreadsheet, counting what’s been used, and placing replacement orders. There’s no real engagement with how we’re using the tools or whether we could be doing things better. The TOM 80 approach is completely different. It gives us real-time inventory visibility, eliminates stockouts, and most importantly, keeps Ceratizit engaged with what’s actually happening on the shop floor.”

The discussions around which products to include in the vending machine are ongoing. Rather than simply replicating existing inventory, Ceratizit is taking a strategic approach. They’re focusing first on high-usage items where extending tool life delivers immediate cost savings, then expanding to cover the broader range of standard tools used across the workshop. Each product is being evaluated not just on a like-for-like cost basis, but on the total cost of ownership.

The consolidation process has already identified opportunities to reduce the overall number of tool types in inventory through strategic product selection. Rather than stocking multiple variations of similar tools, Ceratizit is recommending versatile products from their performance range that can handle multiple applications effectively.

Technical Excellence Meets Service Quality

Beyond the technical attributes of the cutting tools themselves, Atkinson Equipment has been impressed by Ceratizit’s service levels. Lead times, particularly on products delivered from Germany, have exceeded expectations. When urgent requirements arise, Ceratizit’s next-day delivery capability ensures production isn’t compromised.

Atkinson Equipment’s diverse workload, spanning everything from bespoke pump components in stainless steel to high-volume aluminium parts for the fitness industry, demands adaptability from their tooling supplier. “The combination of product quality, competitive pricing, excellent service, and genuinely responsive technical support is what makes Ceratizit special,” reflects Ben Hale.