In 2023, the UK’s manufacturing sector has navigated global challenges and evolving economic factors. Quickgrind, one of the UK’s leading solid carbide tooling manufacturers, has adeptly steered through these challenges with innovation and resilience. MTD magazine sat down with Quickgrind’s leadership team to gain insights into the state of the country’s solid carbide tooling and manufacturing markets, while also discussing broader economic factors affecting the industry.

MTD magazine asked Quickgrind Managing Director, Mr Ross Howell for his assessment of the UK market in 2023.

Ross Howell said: “Through 2023, the UK’s solid carbide tooling industry has continued to demonstrate resilience and growth. With a strong focus on precision engineering and manufacturing, the sector has evolved to meet the demands of cutting-edge industries such as aerospace, automotive and medical. Advances in technology such as CNC machining and 3D printing, have enhanced production processes, delivering innovative, high-quality durable tools.”

Ross Howell said: “Through 2023, the UK’s solid carbide tooling industry has continued to demonstrate resilience and growth. With a strong focus on precision engineering and manufacturing, the sector has evolved to meet the demands of cutting-edge industries such as aerospace, automotive and medical. Advances in technology such as CNC machining and 3D printing, have enhanced production processes, delivering innovative, high-quality durable tools.”

“Sustainability is increasingly important and this is leading to the rise of eco-friendly materials and recycling initiatives. In terms of R&D, the UK remains a global hub for research and development in carbide tooling, fostering innovation and international collaboration. Yes, there continue to be challenging factors such as Brexit, the war in Ukraine, volatile interest rates and supply chain disruptions, but I would say that the solid carbide tooling industry in the UK – and UK manufacturing in general, is thriving and at the forefront of global competitiveness. This has certainly been our experience here at Quickgrind where we continue to innovate, invest and expand.”

MTD magazine asked Brian Pearce, the Sales Director for UK & Ireland at Quickgrind to tell us more about the challenges faced by UK manufacturers of solid carbide tooling?

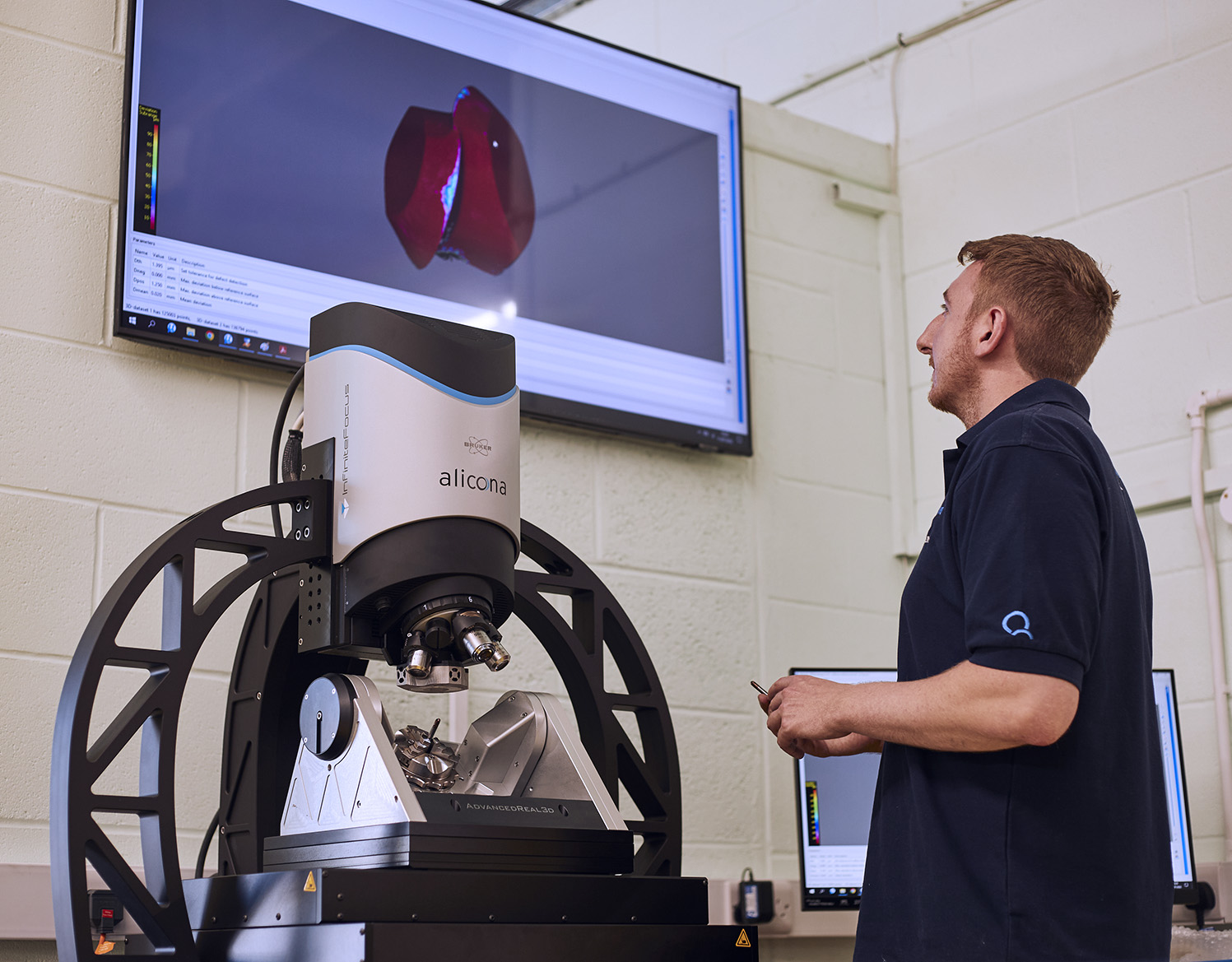

Brian said: “Like every serious business, we continue to face challenges in domestic and international sales, including factors such as global competition, access to some markets, distribution logistics, skills shortages and price pressures. Forward-looking companies like Quickgrind are responding positively to these challenges with improved quality assurance procedures, technological advancements, investment in people and customer relationships and also tool customisation.”

Brian said: “Like every serious business, we continue to face challenges in domestic and international sales, including factors such as global competition, access to some markets, distribution logistics, skills shortages and price pressures. Forward-looking companies like Quickgrind are responding positively to these challenges with improved quality assurance procedures, technological advancements, investment in people and customer relationships and also tool customisation.”

Adding to this, Ross says: “As Brian says, we are finding that our agility in terms of tooling customisation is an attractive proposition to our client partners. Our ‘Infinite Possibilities’ customisation programme ensures we can meet the specific tooling needs of our clients. This is attractive to them as they look to respond to their own manufacturing challenges that are machining-specific and often involve difficult materials in very specialised sectors such as aerospace, automotive and medical. Furthermore, there is the demand for high tolerance levels and repeatability, and of course short lead times. It’s not unusual for our clients to see annual machining savings of 30, 40 or even 50% by adopting the right tool for the right job, which more than outweighs their initial investment.

MTD magazine: Is there anything else you have done to respond to market challenges this year?

Brian responds: “Although we are perhaps best known for our customised tooling, we have also introduced a 400-strong standard tooling range. This means we are now able to offer the same, high-quality tooling that people have come to expect on a next-day basis. We’ve developed the range using our extensive experience and knowledge of the kinds of tools that are needed most often. These tools are of the same quality, precision and repeatability as our bespoke tooling.

Ross says: “Yes, the breadth of our product range offers a sense of security for our customers. They can rely on us to supply the critical tooling they need when they need it. This is another area where you can see our innovation in practice. Our QuickVend tooling inventory management systems help companies maintain tool stock levels, saving on administrative costs and eliminating tool ‘stock-outs’.”

MTD magazine: Quickgrind has also recently launched a new website with e-commerce capability. How has this digital transformation influenced your business and customer experience?

MTD magazine: Quickgrind has also recently launched a new website with e-commerce capability. How has this digital transformation influenced your business and customer experience?

Tim Darch, the Commercial Director, at Quickgrind, responds: “In our continuous effort to enhance user experience and provide unparalleled service, we’ve unveiled a series of digital transformations this year. These ground-breaking changes signify our unwavering commitment to facilitating ease and transparency for our valued customers in their purchasing decisions and business management.”

“Our redesigned website with e-commerce functionality ensures a seamless and user-friendly platform to explore and purchase our wide range of tooling solutions. This evolution ensures that our customers can make informed decisions with just a few clicks, anytime and anywhere.”

“The introduction of data-driven initiatives harnesses the power of analytics and insights. This allows our customers to manage their tooling expenses efficiently, ensuring optimum resource allocation to maximise return on investment. It’s more than a purchase; it’s about making intelligent business decisions backed by data. Furthermore, our upcoming mobile app promises ‘on-the-go’ access, ensuring that our customers remain connected with real-time updates and tools at their fingertips.

We believe in empowering our clients to run their businesses more effectively. Our latest digital initiatives are a testament to this commitment. In challenging times, adaptability is key, and our digital presence has allowed us to maintain a strong connection with our customers while ensuring business continuity.”

MTD magazine: Quickgrind has invested in renewables, including a large solar PV array. How does sustainability factor into your business strategy, and what benefits has it brought?

Tim Darch adds: “Sustainability continues to be a core element of our business strategy. Our proprietary QuickEdge remanufacturing solution gives our clients a repeatable, accurate, timely and cost-effective solution. Recent investment in renewables, including the solar PV array, has allowed us to reduce our environmental footprint while ensuring a stable energy supply. This aligns with our commitment to long-term sustainability, providing both cost savings and environmental benefits.”

MTD magazine: Can you tell us about the remanufacturing or regrind service, and its environmental and cost benefits?

Ross Howell comments: “QuickEdge is a crucial part of our commitment to sustainability. It allows us to remanufacture tools, significantly reducing the need for virgin carbide. This not only lowers costs for our customers but also has a substantial positive impact on the environment. A QuickEdge tool can be reused up to nine times with the same accuracy, repeatability and quality as new tooling, making it an eco-friendly and cost-effective solution.”

MTD magazine: What can we expect from Quickgrind in terms of innovative tooling ranges in R&D for 2024, and how does this align with your strategy considering ongoing economic dynamics?

Ross Howell says: “Looking ahead to 2024, we’re committed to innovation despite the economic challenges. While I can’t reveal all the details, I can assure you that we will continue to push the boundaries of tooling technology. We recognise that in times of change, providing cutting-edge solutions is crucial for our customers’ success.”

In 2023, Quickgrind has demonstrated resilience and adaptability in the face of ongoing global challenges and economic changes through a commitment to customer-centric solutions, sustainability and continuous innovation. As the Tewkesbury manufacturer looks ahead to 2024, it remains dedicated to driving excellence in UK manufacturing by providing innovative tooling solutions tailored to the evolving needs of their customers.