TaeguTec unlocks the productivity potential for machining superalloys

As manufacturers strive to push the boundaries of what’s possible, the role of cutting tool technology has become increasingly crucial. One company at the forefront of this revolution is TaeguTec, a global leader in developing innovative ceramic cutting tools.

In an interview, Jae-Wook (Jay) Lee, the Milling Product Manager at TaeguTec’s world headquarters in Daegu, South Korea, discussed why ceramic tools are increasingly penetrating sectors such as aerospace and power generation.

Traditionally, machining high-temperature alloys such as Inconel has posed significant challenges. These materials are notoriously difficult to machine. Carbide tools often struggle to meet the demands, resulting in premature wear, reduced tool life, and compromised productivity.

Ceramic tooling has developed over the past 20 years, with initial applications focused on machining cast iron and hardened materials using silicon nitride ceramics. However, as the industry shifted towards machining tougher alloys like nickel-based superalloys, new ceramic grades are necessary. This led to the creation of SiAlON ceramics, specifically engineered to address the unique challenges associated with machining HRSA.

The key difference between traditional silicon nitride ceramics and SiAlON is their ability to withstand chemical reactivity and extreme heat. Where silicon nitride tools would rapidly degrade due to early wear, SiAlON ceramics remain stable under thermal loads.

“For machining HRA and HRSA materials, like Inconel, the silicon nitride ceramic inserts we have developed are a game-changer,” explains Lee. “The properties of our latest ceramic materials vastly differ from those used for machining cast iron or hardened steel. We’ve engineered our SiAlON-based ceramics to excel in these challenging applications.”

The key advantages lie in the ability to withstand extreme temperatures and stresses encountered during machining of superalloys. “Carbide tools tend to react with the workpiece at high temperatures, leading to rapid wear despite the low cutting speed. “Our ceramic inserts are much more resistant to this thermal wear, allowing us to push cutting speeds to unprecedented levels.”

Boosting Productivity with Ceramic Inserts

One of the most striking benefits of TaeguTec’s ceramic cutting tools is their ability to dramatically increase productivity. “We’ve seen cases where our ceramic inserts can achieve cutting speeds at a minimum of 20 times faster than traditional carbide tools,” Lee reveals. This translates to a massive boost in metal removal rates and overall efficiency.”

The secret behind this performance lies in the design and geometry of TaeguTec’s ceramic inserts. “We’ve developed a high-feed shape that allows us to increase both the cutting speed and the feed rate,” explains Lee. “This, combined with the inherent properties of the ceramic material, enables us to push the boundaries of what’s possible in terms of productivity.”

To illustrate the point, Lee shares a case study from a leading aerospace company in Brazil. “They previously used solid carbide tools for machining Inconel 718 components, with a cutting speed of around 35m/min and a metal removal rate of just 10.5cm³/min. After switching to our ceramic inserts, they increased the cutting speed to 1000m/min and the metal removal rate (MRR) to an astounding 213cm³/min – a 20-fold improvement in productivity!”

Overcoming the Mindset Barrier

Despite their advantages, ceramic tools have faced resistance in markets such as the UK and Western Europe. Many machinists remain cautious about potential tool breakage and short tool life. There is a strong preference for the perceived durability of carbide tools, even though carbide struggles with high-temperature alloys and requires substantial coolant use to manage heat.

Ceramic inserts have proven themselves in global aerospace hubs and power generation sectors. While tool life for ceramics may be limited (sometimes as little as five minutes), the incredible increase in cutting speed and productivity far outweighs the trade-off.

Typically, a cutting tool averages 3% of the machining cost, with labour, hourly machine rates, power consumption, and business overheads absorbing the remaining 90+%. If a ceramic insert can deliver stratospheric machining results that drastically improve the machine utilisation rate, reducing the 90+% of machine cost whilst slightly increasing the 3% tooling cost, it doesn’t take a rocket scientist to work out the benefits of ceramic tooling.

For example, some aerospace manufacturers keep 50 identical ceramic tools preloaded in their machines. This strategy optimises throughput by more than tenfold, rendering the shorter tool life irrelevant. After all, the tool life is only shorter in minutes – in terms of material removal rate (MRR), ceramic tools far exceed the performance of carbide.

To address challenges related to perception, TaeguTec has made significant investments in robust clamping systems and insert geometries. “We’ve designed ceramic inserts with a high-feed shape that boosts productivity but also enhances the stability and reliability of the cutting process,” explains Lee.

“It’s not just about the tool – it’s about changing the entire machining strategy,” says Lee. “We work closely with our customers to help them understand the benefits of running at higher speeds and lower depths of cut.”

In a recent case, a new screw-type ceramic insert- claimed to be the first of its kind globally- was tested in aerospace manufacturing. Despite initial concerns about clamping stability and heat transfer, the insert performed flawlessly in high-temperature machining trials.

Expanding the Ceramic Frontier

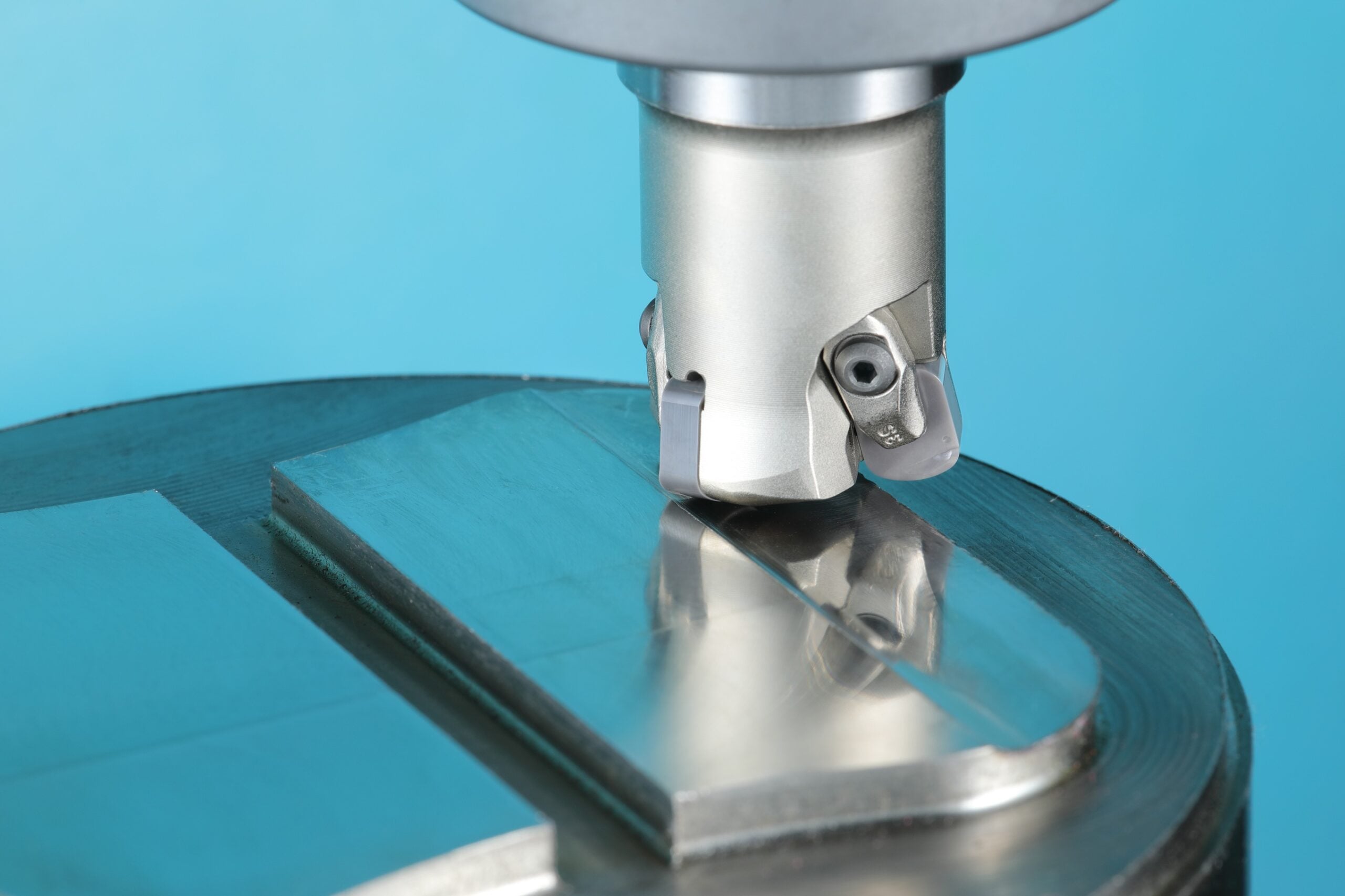

Modern ceramic tooling isn’t just about material composition. Geometric innovation is crucial in maximising the performance of ceramic inserts. TaeguTec has introduced high-feed geometries and unique clamping designs like the screw-type inserts that further push the boundaries of what ceramics can achieve.

Taegutec has not only developed industry-leading ceramic grades that outperform rival products, but it has also utilized its position as a world leader in high-feed machining to incorporate innovative cutting geometries into its ceramic product lines.

TaeguTec has expanded its ceramic ranges to include round inserts and high-feed geometries, tailoring its ceramic product lines to cover a broader array of machining scenarios. The latest addition to the indexable CeramicSFeed line features a range of 16, 20, and 25mm diameter tool holders with two or four insert pockets that accommodate TaeguTec’s latest BNGX 06 size inserts. These smaller inserts enable more insert positions per tool, allowing for higher productivity.

“We’re constantly pushing the boundaries of what’s possible with ceramic technology,” says Lee. One focus area is developing ceramic grades suitable for machining a wider range of materials, including stainless steel and titanium alloys.

TaeguTec has also developed what is claimed to be the industry’s first screw-type insert clamping system for indexable ceramic tools. “This is a true breakthrough in ceramic cutting tool design,” Lee enthuses. “By incorporating a unique screw-type clamping mechanism, we’ve addressed the common concerns about insert breakage and clamping issues that have historically held back the adoption of ceramic tools.”

“Not only does it provide a secure and stable clamping solution, but it also allows us to make the cutter diameter smaller. In the end, it can replace solid carbide end mills by increasing the cutting speed and feed rate further, unlocking even greater productivity gains for our customers,” explains Lee.

The Future of Ceramic Cutting Tools

As the aerospace and power generation industries continue pushing boundaries, Lee believes ceramic cutting tools will play a pivotal role. “The trend in the industry is clear — manufacturers are increasingly focused on maximising productivity and efficiency while also considering the environmental impact of their operations,” he says.

“Ceramic inserts are perfectly positioned to meet these demands, with their ability to deliver unparalleled metal removal rates and their inherent eco-friendliness, as they eliminate the need for copious coolant usage.”

Looking ahead, Lee envisions a future where ceramic cutting tools become the norm rather than the exception in high-performance machining applications. “We’re already seeing a significant shift in mindset, particularly among more forward-thinking manufacturers willing to embrace new technologies,” he says.

Ceramic cutting tools represent a paradigm shift in machining difficult materials like Inconel and other superalloys. By overcoming the traditional limitations of carbide tooling, ceramics unlock unprecedented productivity, efficiency, and sustainability. For industries focused on high-temperature applications, ceramic tooling is not just an alternative; it’s the next standard.