Cwm Engineering Ltd has been on an acquisition trail over the last few years to target growth in high-tech industry sectors. As part of its journey, the West Wales company has invested in five machine tools in the last three years. Now, the company is implementing a dedicated inspection department with high-end metrology equipment – that is why it has just installed a CMM and a surface roughness machine from Mitutoyo.

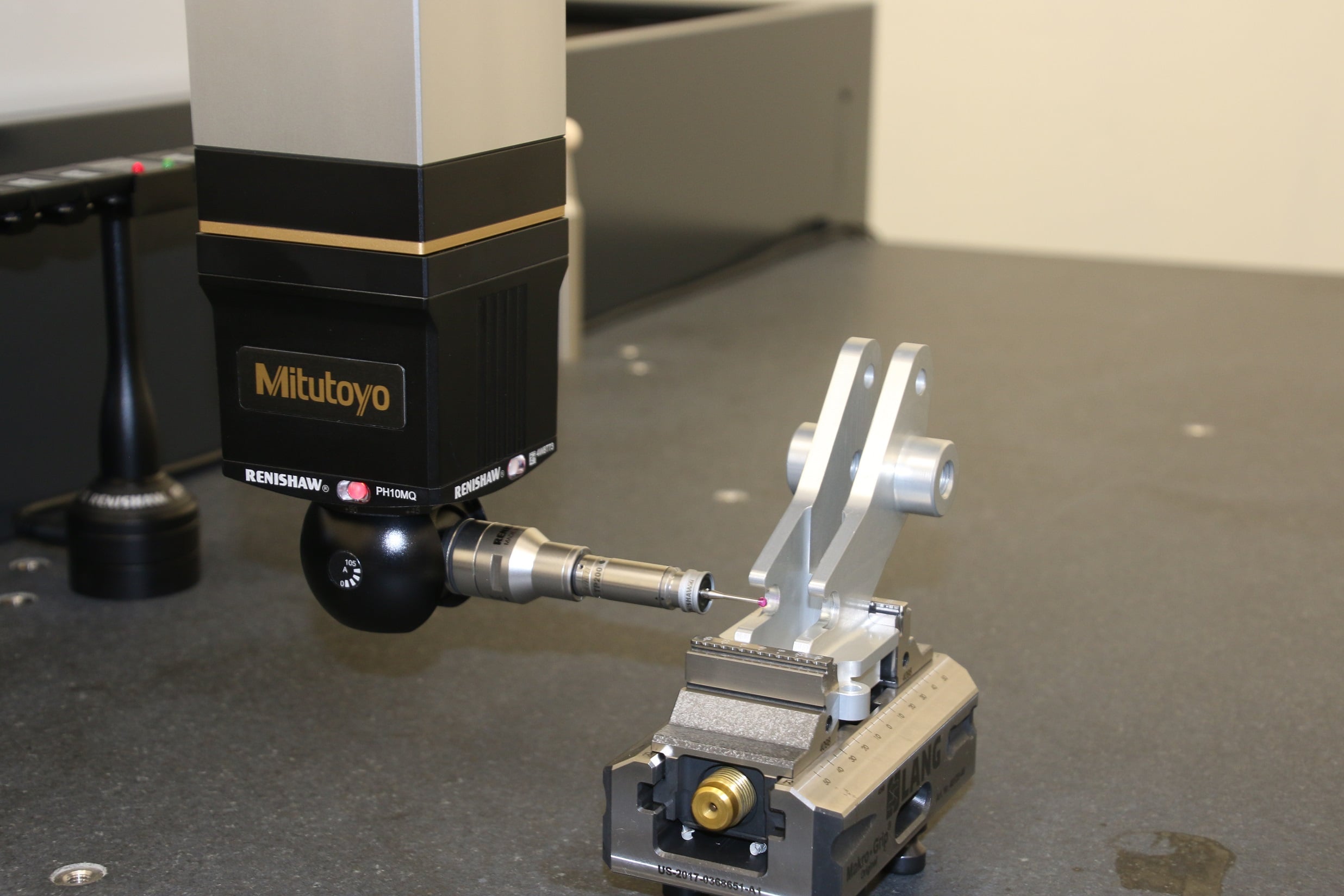

With a machine shop full of turning centres and 3, 4 and 5-axis machining centres, Cross Hands based Cwm Engineering is aiming to expand its work with aerospace OEMs and Tier 1 manufacturers. To do this, it has just built a dedicated temperature-controlled inspection department with a Mitutoyo Crysta-Apex V 7106 CNC Coordinate Measurement Machine (CMM) and a Mitutoyo surface roughness machine.

Founded in 2011, the ISO: 9001 certified company started its metrology journey like all subcontract businesses – with precision hand tools. In 2014, the business bought a manual Mitutoyo CMM. This was subsequently followed by two shop floor CMMs to allow operators to inspect at the side of the machines to prevent potential bottlenecks on the Mitutoyo CMM. However, Cwm Engineering realised that to win business from its OEM and Tier 1 target audience, it needed to stand out with a dedicated temperature-controlled facility with high-end metrology technology.

Commenting upon this investment, Cwm Engineering’s Managing Director Malcolm Walters says: “To set ourselves apart from other subcontract companies, we recognised the importance of investing in a dedicated temperature-controlled quality assurance department. We are fully aware that when potential customers visit a subcontract manufacturer, they want to see a dedicated metrology department to instil confidence in their supply chain choices. When it came to selecting equipment for this dedicated department, Mitutoyo was the standout brand for our business. Mitutoyo is a brand that everyone knows and respects as an industry leader, and our previous experience with Mitutoyo gave us the confidence that it was the brand for our business. Our previous experience with Mitutoyo was exceptional.”

Cwm Engineering invested in a Mitutoyo Crysta-Apex V 7106 CNC CMM that was delivered in April along with a surface roughness machine. Alluding to why the company invested in the Mitutoyo Crysta-Apex V 7106, Malcolm adds: “We chose this machine as it has a measurement range of 700 by 1000 by 600mm that is packed into a small footprint. The compact footprint is perfect for our inspection department and the work area covers the diverse dimensions of the work we undertake.”

The Mitutoyo Crysta-Apex V 7106 is crammed with the latest technology and this includes Mitutoyo’s ABS linear scales, SMS capability for status and service monitoring and Mitutoyo’s renowned MCOSMOS software. The Crysta-Apex V 7106 is extremely accurate and fast with high acceleration rates which are credited to its lightweight bridge construction, temperature compensation sensors and the UC480 controller that supports the multi-sensor and SMS functionality (Smart Measuring System). With a digital step of 0.1µm, the machine has an accuracy maximum permissible error of (1,7+0,3L/100)µm with a 3D acceleration rate of 2,309mm/s2.

Discussing how the Crysta-Apex V 7106 will streamline throughput at Cwm Engineering, Andrew Ritchie, the Systems and Operations Manager adds: “When we are programming parts offline with our CAM system, we can simultaneously send the files to our CMM for programme creation. This ensures that the CMM programme is prepared and ready to inspect the parts whilst they are in production.”

As well as investing in the Crysta-Apex V 7106, Cwm Engineering also purchased a Mitutoyo surface roughness measuring machine. Alluding to this, Andrew adds: “Historically, we have used a sample gauge and this has proven reasonably accurate. However, our variation of work can require surface finishes from as high as Ra3.2 in general subcontract work to as low as Ra0.4 for parts in the electronics, communications and ultrasonic industries. In some instances where customers subsequently surface coat or treat parts, they require a surface finish of ‘“That” and not better’ – the new testing machine will certainly support us in such instances.”