🎧Revolutionising factory automation with intelligent measurement solutions

🎧Revolutionising factory automation with intelligent measurement solutions

According to Pralhad Thapa, Department Manager at Mitutoyo Europe, an expert in dimensional metrology and automation: “We are confident we can address these issues for our customers, providing unattended measurement solutions that are easy to operate and available at a reasonable price.”

In a presentation, it was this opening gambit that embodies both the philosophy of the new SmartMeasure AL system and Mitutoyo’s commitment to precision. Building upon decades of expertise in CMMs, this turnkey solution addresses the fundamental pain points expressed by customers across diverse industrial sectors.

Predicting the Market Demands

The persistent shortage of skilled manpower has created operational bottlenecks, whilst increasing quality demands have elevated the importance of precision measurement. Traditional approaches that rely heavily on manual intervention and specialised expertise are proving inadequate in meeting the evolving demands in the face of a skills crisis.

Mitutoyo’s SmartMeasure AL emerged from extensive customer consultations across European markets. Industry feedback consistently highlighted specific requirements: systems capable of easing labour shortages, reducing human error, providing stable measurement capabilities, supporting high-mix production environments, and enabling unattended operation during night shifts and breaks—all whilst maintaining cost-effectiveness. The industry isn’t asking for much there, then….

Developing SmartMeasure AL as a standardised product, rather than a bespoke project-based solution, represents a significant strategic shift. Thapa explains this fundamental change: “Our goal with SmartMeasure AL is to develop this fully automated solution as a product, so that our customers can order it from our website, our B2B shop, or through other means. This approach enables reduced development costs, shorter delivery times, and more competitive pricing compared to traditional custom automation projects that Mitutoyo has delivered over the past three decades.”

System Architecture and Core Concept

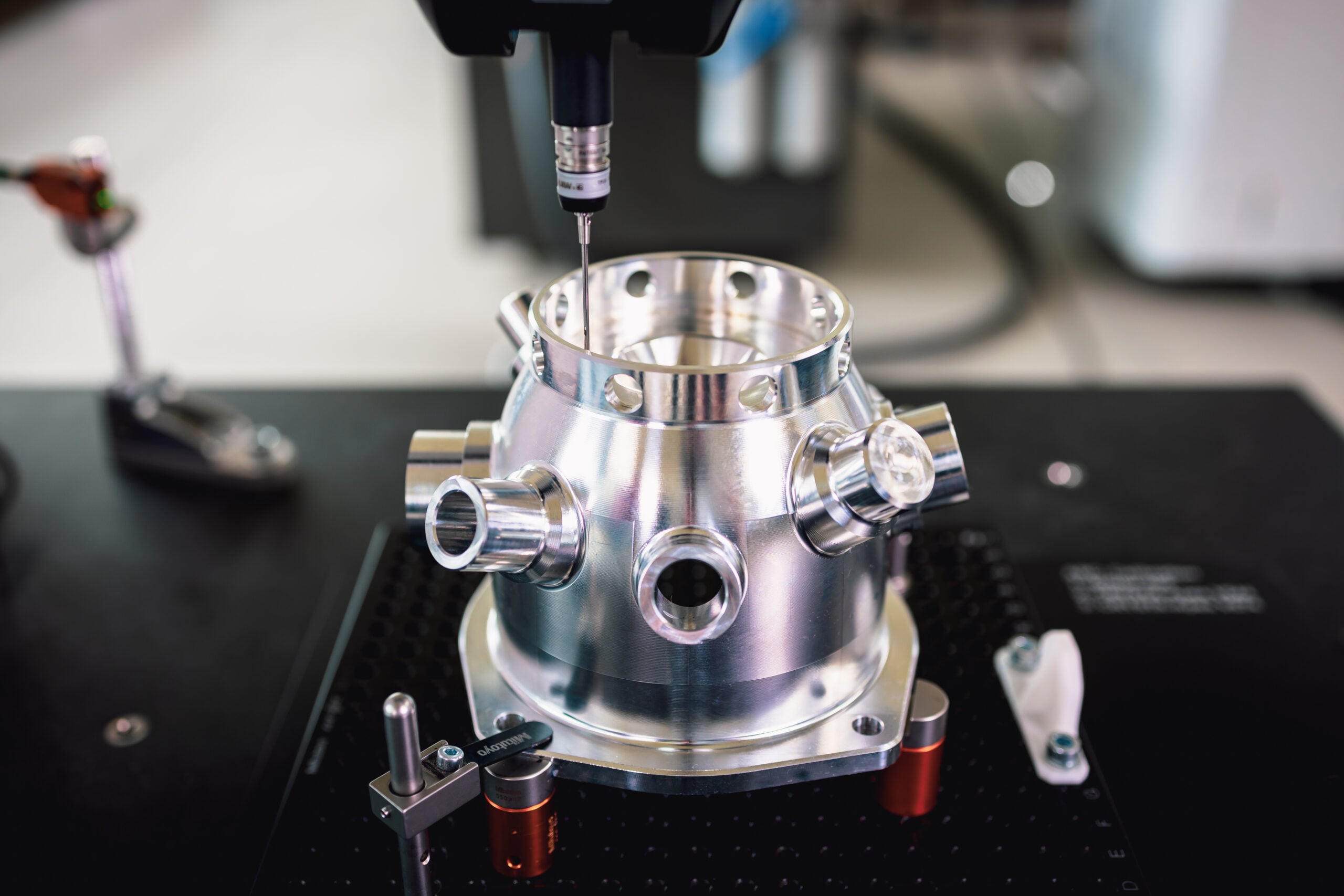

SmartMeasure AL employs a three-component architecture comprising a CMM, an industrial robot system, and supporting infrastructure including racks, pallets, fixtures, sensors, and integrated software. This modular philosophy allows for flexible configuration according to specific customer requirements whilst maintaining standardisation benefits.

The system’s operational principle centres on a 12-part pallet rack configuration. When an operator initiates the measurement cycle, the integrated robot retrieves parts from designated positions, transports them to the CMM and returns them to the rack with a clear indication of pass/fail status. This automation eliminates the need for continuous operator supervision whilst maintaining measurement accuracy and traceability.

Central to the system’s intelligence is Mitutoyo’s ESPRIT software platform. Unlike conventional automation systems that rely on PLCs requiring specialist expertise, ESPRIT provides an intuitive graphical user interface accessible to operators with basic technical knowledge. As Thapa emphasises: “We really focused on developing the graphical user interface, because we know operator knowledge is limited and the market has a skills deficiency.”

Technical Specifications

SmartMeasure AL demonstrates versatility through its compatibility with multiple Mitutoyo CMM models, including the CRYSTA-Apex S series (544, 574, 776, 7106, and 9106 configurations).

The robotic component utilises FANUC CRX series of collaborative robots, available in two payload configurations: CRX-10iA/L and CRX-20iA/L with 10 and 20kg payload, respectively. This dual-option approach ensures optimal matching between robot capability and workpiece requirements. Importantly, Mitutoyo maintains openness to alternative robot manufacturers, allowing customer preference integration where requirements exist.

Advanced Software Features and Capabilities

The ESPRIT software platform incorporates several features designed to enhance productivity and operational efficiency. Multiple part measurement capability allows simultaneous measurement of several small components within a single 250 by 250mm pallet, particularly beneficial for manufacturers where part sizes permit batch processing.

The re-measure functionality demonstrates the system’s intelligence. Following overnight automated measurement cycles, operators can selectively re-measure only those parts flagged as non-conforming, eliminating unnecessary repeat measurements of acceptable components.

RFID technology provides part tracking and traceability where each component’s measurement history can be automatically logged and integrated with broader quality management systems to provide audit trails. Real-time connectivity capabilities facilitate integration with external systems, including ERP platforms and manufacturing execution systems. This connectivity supports Industry 4.0 initiatives and enables data-driven decision making.

Closed-Loop Manufacturing Integration

SmartMeasure AL’s closed-loop manufacturing capability represents a significant advancement in process control. The system automatically analyses measurement data and calculates necessary tool offsets for upstream CNC machining operations. When deviations are detected, ESPRIT software automatically transmits correction values to the relevant CNC machines, enabling real-time process optimisation. This closed-loop approach reduces setup times and scrap rates through proactive process control. The automatic feedback mechanism minimises the time between problem detection and correction implementation, crucial for maintaining tight tolerances in high-volume production environments.

Competitive Advantages

SmartMeasure AL’s primary competitive advantage lies in its product-based approach rather than project-based delivery. Customers can order complete systems through standard commercial channels, including Mitutoyo’s B2B platforms, enabling predictable pricing, standardised delivery schedules, and reduced implementation complexity. Thapa notes the market reception: “The feedback has been very positive. When customers came and saw our product, they said, ‘Unattended measurement. The GUI is very simple to use, and an operator with minimum knowledge can operate this fully automated system.’”

The system’s compact footprint addresses space constraints, and despite incorporating a complete CMM, robot system, and part handling infrastructure, SmartMeasure AL requires minimal floor space. Cost-effectiveness extends beyond initial capital investment. The elimination of PLC programming requirements reduces implementation and maintenance costs, whilst the intuitive ESPRIT interface minimises operator training requirements.

Future Development and Expansion

Mitutoyo’s roadmap for SmartMeasure AL encompasses expansion across the company’s broader product portfolio. Future developments will extend automation capabilities to laser measuring machines, contour and roundness measuring systems, and surface texture measurement equipment, creating a comprehensive automated measurement ecosystem. Thapa confirms: “We will continue to develop this product and expand to support other products from Mitutoyo. We will continue to support our customers in the field of factory automation, help them and understand their pain points and see where Mitutoyo technology can increase productivity.”

Conclusion

Mitutoyo’s SmartMeasure AL represents a paradigm shift in automated measurement solutions. By addressing critical industry challenges, including skilled labour shortages, quality demands, and operational efficiency requirements, the system provides a comprehensive solution.

The product’s success lies in its synthesis of proven measurement technologies, intelligent software platforms, and flexible automation capabilities within a standardised, cost-effective package.