At the cutting edge of innovation, the Infinite Possibilities programme from Quickgrind sets new standards to deliver the optimum tooling for medical projects. Infinite Possibilities encourages manufacturers to look beyond standard catalogue cutting tools and to work with Quickgrind to develop solution-specific tooling that is ideally matched to manufacturing requirements. Just as no two knees are the same, no manufacturing processes are the same.

This philosophy pays dividends in the field of medical implants, where demand is growing as life expectancies continue to lengthen. Arthritis, osteoporosis and obesity all result in an increasing need for prosthetics, particularly total knee and hip replacement components. Manufacturers are required to scale up production without over-increasing the price per part. Not only are production speeds and costs an issue, but manufacturers also need to be at the forefront when it comes to understanding the latest materials.

Biocompatible metallic materials need to be hard-wearing and require high levels of surface finish to enable the plastic parts such as ultra-high molecular weight polyethylene to achieve their expected lifetime of 20 years or more. Absolute smoothness is a must to protect against wear and early failure. For machining these materials as well as medical-grade titanium and cobalt chrome, Quickgrind has a range of tooling solutions.

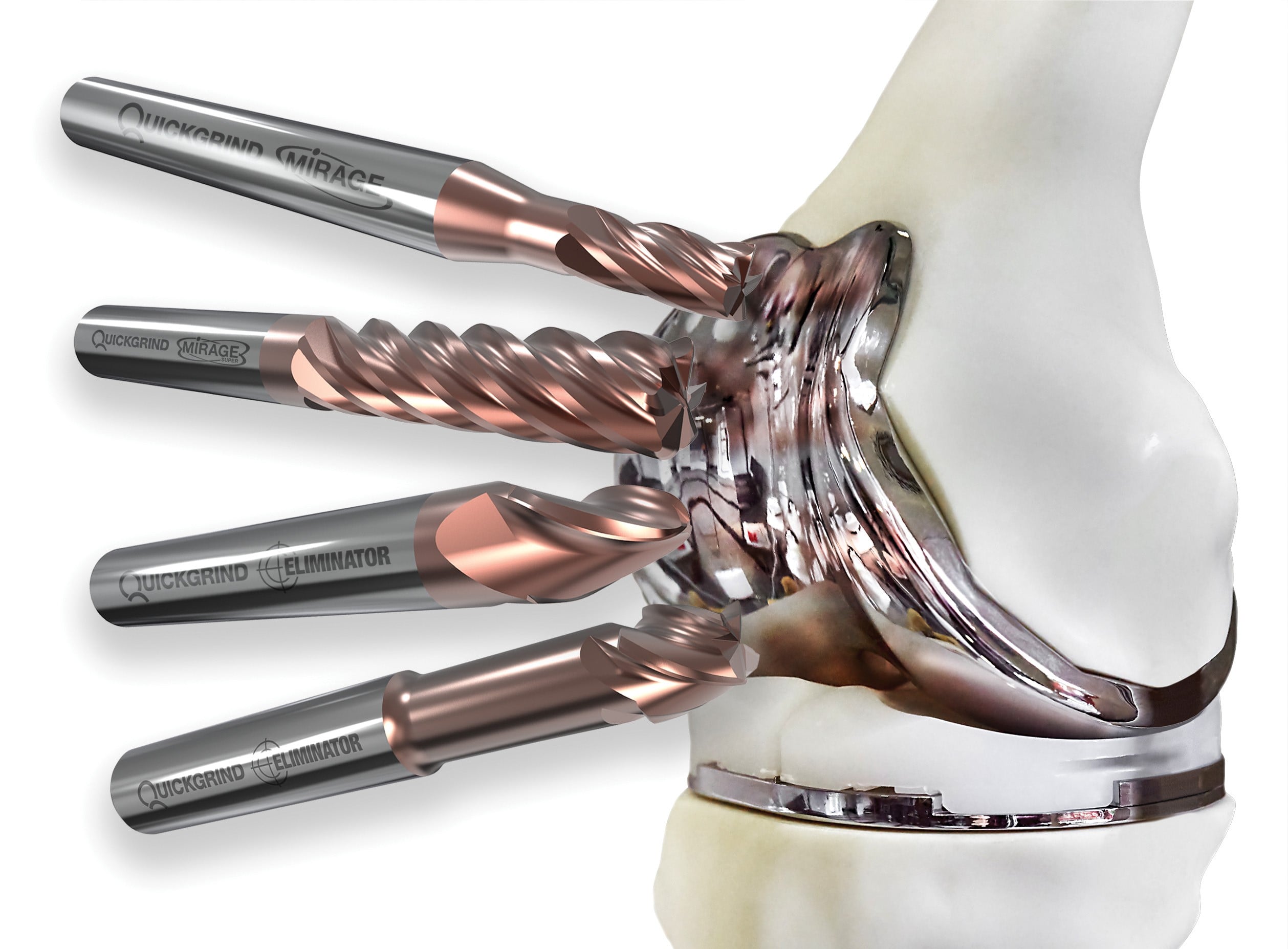

A game changer for the medical industry has been the 3-flute Eliminator Conical Barrel Tool (CBT). The flute radii adjusted for each application enables a large radius of curvature (Rw) to be machined, the Eliminator gives an increased contact area for larger step-down distances without any detrimental impact on the theoretical scallop height. The result is highly accurate surfaces with excellent characteristics and finishes that can reduce the need for polishing and other finishing processes, thereby reducing manufacturing costs.

As a company always innovating, Quickgrind has made a fascinating addition to the Eliminator barrel tool range – the Concave Conical Barrel Tool (CCBT). This tool has been developed for convex surfaces such as femoral knee joints. The reduction in cycle times through greatly improved step down and excellent Ra finish is achieved by mimicking the convex surface being produced. If you consider the condyle surfaces being machined and the low Ra finish required, they do not lend themselves to many types of tools. Conventional ballnose endmill scanning works -but with a long cycle time. The conical barrel tools have already shown cycle time savings of up to 90% with the convex flute radii – now it’s time to deliver the same savings using a convex-shaped tool for convex surfaces. The cycle time savings over the CBT have been between 20 and 40% with equally low Ra surface finishes.

Other products ideal for the medical industry include the Undercut tool, a tool designed with the optimal number of flutes, flute geometry and coating to provide engineers with the optimal tool. If necessary, Quickgrind can provide top and bottom radii as well as amend the number of teeth to allow for the most efficient cutting data to be used. Another popular tool is the Panther femoral step drill. As the name suggests, it is perfect for femoral joints as the multi-diameter drills are designed to create multiple bores in one pass whilst reducing cycle times and machining costs.

Complementing the Panther is the Quickgrind Chamfer tool. A versatile solution, it can be used for several machining operations such as bevelling, deburring, spotting and countersinking.

For all things medical milling, the 6-flute Mirage Super applies its clever design and the latest grade of carbide and coating technology to take machining to new heights of performance for critical parts in superalloys. Quickgrind has utilised the toughest substrate available with a high wear-resistant coating and polished flutes that have been combined with a balanced option for the highest possible component quality. Complementing the Super Mirage is the Mirage. This range is ideal for when non-standard features are needed, such as a greater overall length, an extended neck or a smaller diameter. Rather than reverting to modular tool holding or even special tool holders, Quickgrind can design the optimal tool.