With the new Starrag HEC 800 X5 MT machining centre, the machining team at Neuson Hydrotec GmbH in Linz can machine complex housings with numerous holes at different angles with maximum precision – in a single clamping position and in half the time.

With around 50 employees, contract manufacturing is the largest business unit at Neuson Hydrotec GmbH. Walter Füreder, one of the two Managing Directors responsible for this division, says: “We generate around half of our turnover with our contract work. Twenty percent of this involves doing the groundwork for other business units.”

Components for injection moulding machines are also part of the recurring contract work, such as shredder shafts and bearing blocks, all supplied to machine tool manufacturers. Karl Kordik, Sales Manager for contract manufacturing, says: “We supply the largest proportion of our work, around 40%, to the plastics recycling sector.”

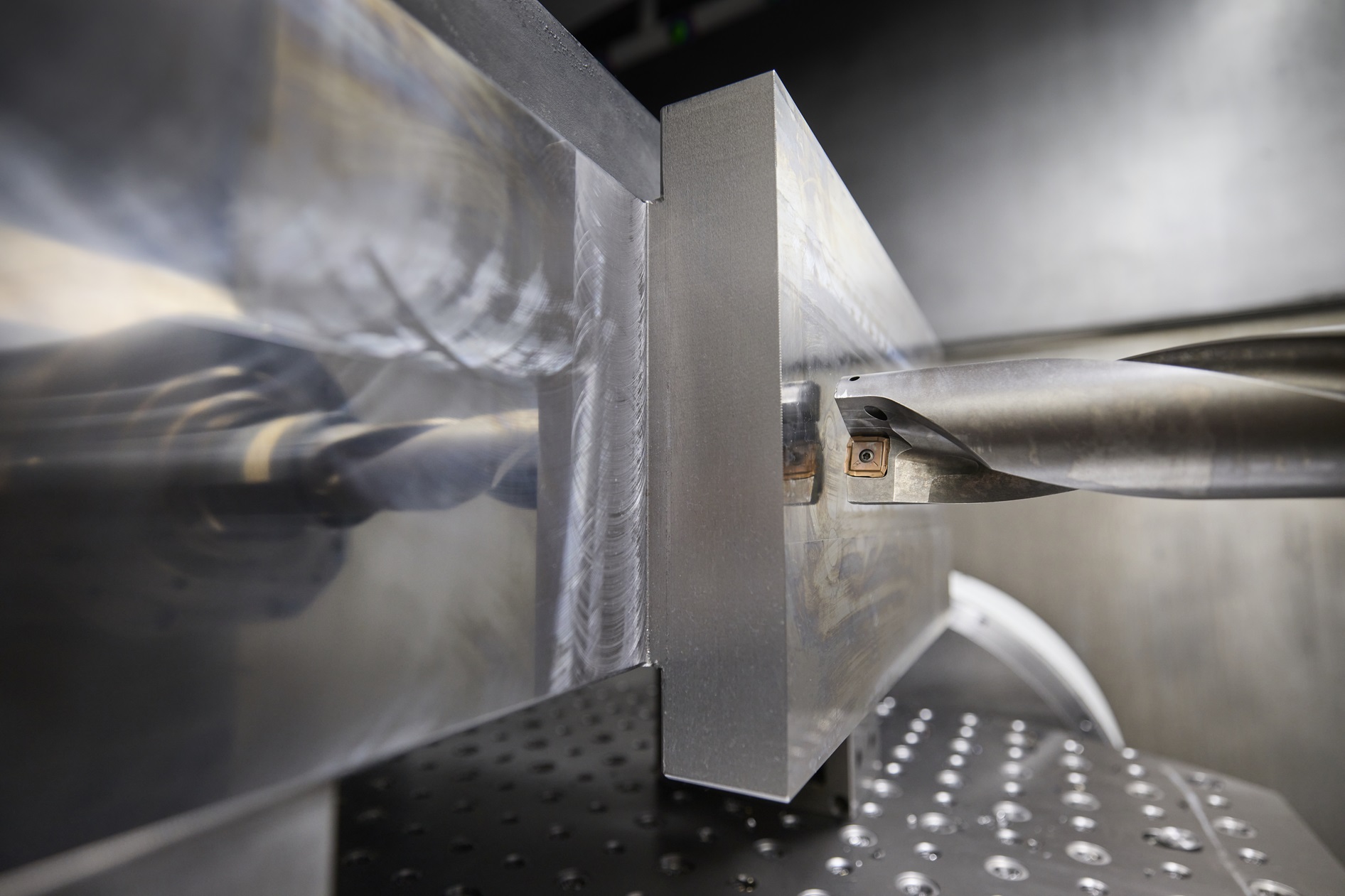

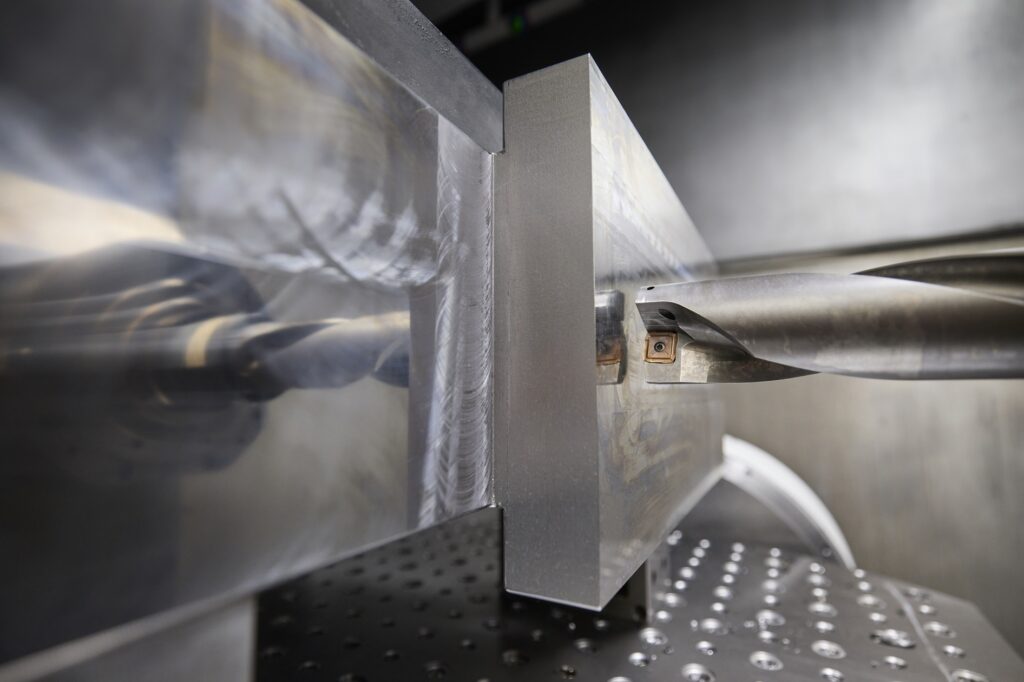

The services range from procuring raw material to CNC milling, grinding, lapping, honing, welding and superfinishing to pre-assembly. The contract manufacturing department has various CNC turning and grinding machines and several machining centres with pallet pools. The highlight is the HEC 800 5X MT 5-axis machining centre purchased in May 2024. This investment was triggered by a complex component for a plastics recycling machine that requires turning and milling, and numerous holes have to be drilled at different angles. In this recycling plant, the used plastics are heated to around 400 degrees after shredding. A spindle presses the liquefied mass through a plate with tens of thousands of holes about 0.2mm in diameter, which retains contaminants. It contains intricate contours and numerous channels through which the contaminated and cleaned plastic first flows. “One hole runs through the entire component, and other channels meet at a certain angle,” says Karl Kordik.

High precision is required for fluidic reasons where the channels must not be offset when they meet. “We manage this because we achieve a positioning accuracy per hole of less than 0.03mm. Although that doesn’t sound particularly difficult, the value corresponds to only a few μm per axis if the holes are drilled at 45 degrees.”

Until recently, the contract manufacturers were producing this housing on a vertical turning and boring mill and a three-axis milling machine, in seven clamping positions. When the customer ordered significantly larger quantities, Neuson Hydrotec decided to modernise production to reduce manufacturing times.

There were several reasons why the decision was made in favour of the HEC 800 5X MT. According to Kordik, one crucial factor was that the HEC 800 allows the component to be clamped vertically: “These components can only be clamped on a horizontal turning and milling centre with great difficulty. Fast, automated workpiece replacement is even more difficult. The HEC 800 has a standard dual pallet changer, enabling setup parallel to the primary processing time.”

On the HEC 800 5X, the 5th axis is located in the workpiece, not the tool. The decisive factor was the possibility of obtaining a bed extension along the Z-axis and an extended Y-axis. Kordik describes the background: “We want to clamp components with a length of 1.1m and drill through. The standard Z-axis path of 1.3m is insufficient for this.” Starrag supplied the HEC 800 5X MT with travel paths of 2,050mm along the Z-axis and 1,300mm along the Y-axis. “No other machine manufacturer had offered such extensions. We would have had to switch to much larger machines.”

The control software for interpolation turning was also on our ’to-buy list’. This is because the laser filter housing requires a 350mm hole offset from the centre by 8mm. “Thanks to the precisely controlled interpolation of the X and Y-axes, we can create this without any problems,” confirms Karl Kordik.

Producing the eccentric hole using interpolation turning saves more time. In the case of the filter housing, reducing the number of clamping positions from seven to one was possible. The time saving is 48%.