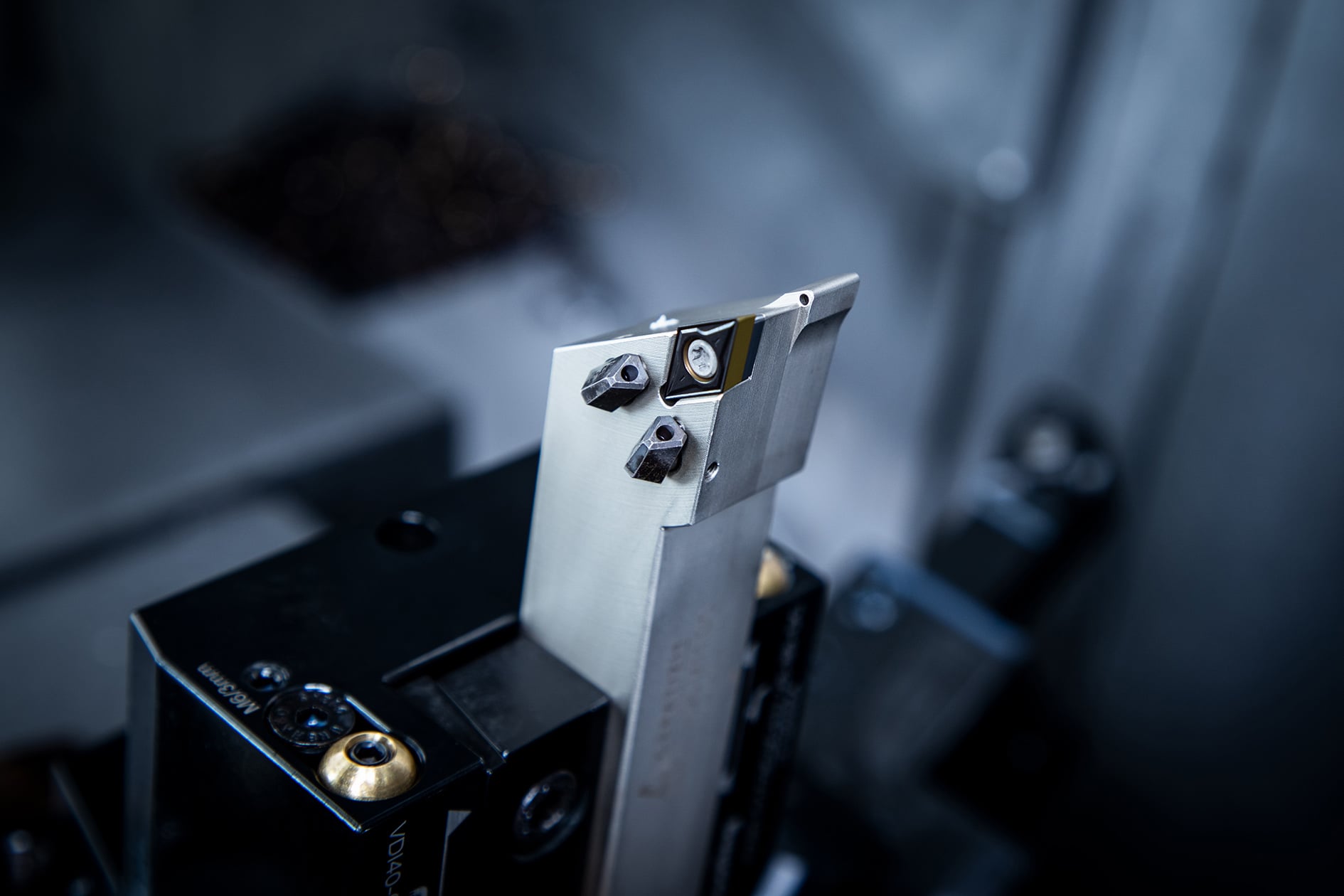

CERATIZIT’s development specialists recently upgraded the MaxiLock-S turning tool holder to incorporate the DirectCooling holder. Two nozzles now apply coolant directly to the cutting edge – enhancing overall performance and tool life.

With a focus on sustainability and efficient use of resources, the concept of DirectCooling from CERATIZIT brings a minimalist approach. In a typical turning scenario coolant is distributed extensively to the machining area, however with the new MaxiLock-S DC turning tool holders, which form part of the DirectCooling (DC) system, coolant is applied precisely to the cutting edge via two internal holes. This guarantees that coolant is applied precisely to the cutting edge, with one hole targeting the rake face from above and the other to the flank from below. The addition of flank cooling boosts service life by 60% compared with cooling exclusively on the rake face.

“We wanted to take what has since become the norm for grooving holders and apply it to our turning tool holders for external turning applications. This resulted in the MaxiLock-S DC range, which allows customers to boost general process security and cutting values thanks to targeted cooling. Compared with conventional cooling, DirectCooling achieves service life improvements of around 65%, regardless of material and machining application,” explains Stefan Karl, Product Manager for Cutting Tools at CERATIZIT. CERATIZIT has also reworked the insert seat, adding greater stability to the clamping of the indexable insert. This reduces wear on the cutting edge and creates a better surface finish on the workpiece.

DirectCooling can be used for any application and works with a minimum coolant pressure of just 10 bar where this is fed through the turning centre turret. “Of course, the higher the pressure, the better chips are broken and cleared away. This is particularly beneficial to those machining steel especially in combination with our new ISO-P indexable insert. However, the MaxiLock-S DC is just as comfortable on stainless and difficult-to-machine materials,” says Stefan Karl.