🎧Precision at scale with Mastercam

In aerospace tooling manufacture, where tolerances are in microns and complexity is common, Leicester-based JWA CNC Precision has built a reputation for quality and speed. The company introduces two new component variations daily while maintaining five-micron tolerances, thanks to a 25-year partnership with Mastercam CAM software that has evolved with its technology.

Founded in 1985 and incorporated in 2000, JWA CNC Precision has built a reputation as a trusted partner to leading aerospace companies. The company specialises in manufacturing tooling for aerospace cooling holes—critical components that enable jet engines to operate at extreme temperatures by directing cooling air across turbine blades.

JWA’s operations reveal a large manufacturing challenge. Pete Wood explains: “We’ve accumulated around 9,000 component part numbers over the years, including long-serving components that become popular again. We’re typically doing about 2,000 unique part numbers annually.”

Evolving Capabilities Through Partnership

JWA’s relationship with Mastercam extends back 25 years, making it one of the company’s longest-standing technology partnerships. “We started out at a basic level using 3-axis milling and on to 3+2. Through the years, we’ve developed as our skills and demands have increased,” says Pete.

“In more recent years, we’ve been investing in 5-axis machinery, and Mastercam has been the obvious go-to choice for us on 5-axis machining.”

Driving Operational Excellence

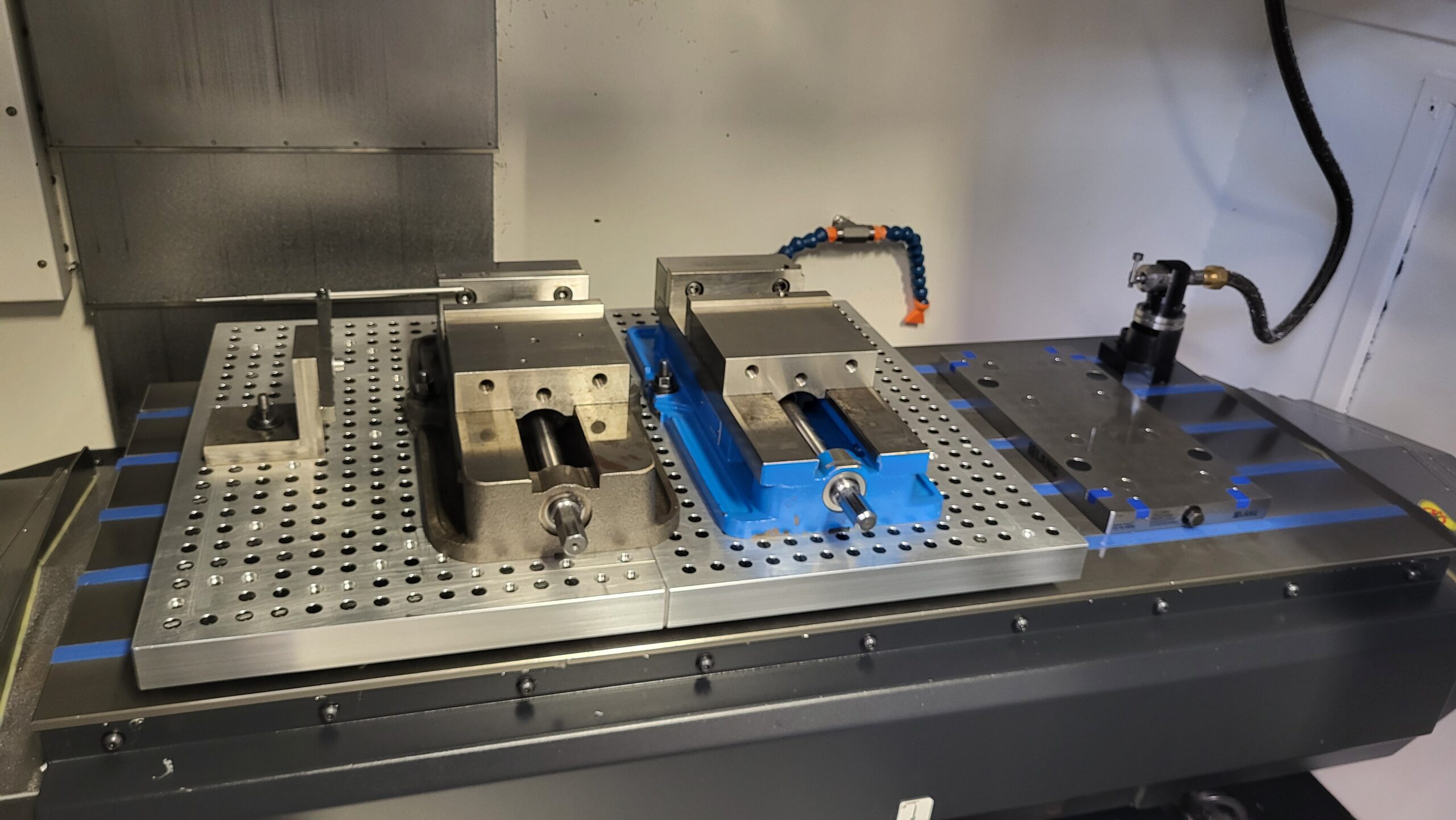

What distinguishes JWA’s implementation of Mastercam is the depth of customisation and standardisation achieved. Tim Shillabeer from JWA CNC adds: “We have very comprehensive tool libraries. We have a lot of default settings, so that everybody’s working to the same standard. We have tool reports actively set up so that we can list our tools and create setup sheets, and we have simulations for all our machines.”

This systematic approach to CAM programming ensures consistency regardless of which programmer creates the toolpath or which machinist sets up the job.

“All of those features enable us to do quick, reliable setups with a common standard between whoever does it. We produce a programme and a method that is pretty typical, so that everybody’s familiar with the way we work. This makes our setups quite easy for anybody to pick up a job and create a fast setup time with a reliable process.”

For Pete, the impact on productivity is tangible. “Mastercam really helps us reduce the downtime on the machines. Our biggest challenge is the time it takes from finishing the previous job to starting the first part of your next job, and Mastercam has enabled us to narrow that gap by helping us with the documentation.”

The comprehensive approach to tool libraries means that every programme generated is as close to right first time as possible, eliminating the need for shop floor modifications.

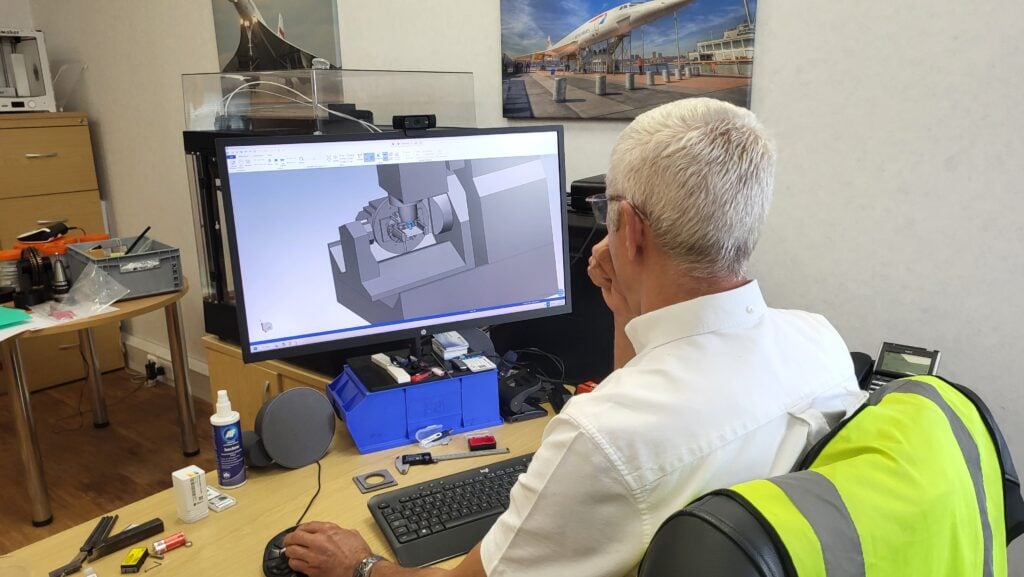

Simulation as a Confidence Tool

“It’s not necessarily just about new product introduction,” Pete explains. “It’s the fact that we’ve got it geared up, so our junior machinists don’t even need to be programmers. They can open up Mastercam and just run the simulation to see what’s going to happen when they put a programme in the machine.”

The confidence that comprehensive simulation provides has practical implications for manufacturing efficiency. “It gives staff confidence to tread less carefully when they’re setting up a new job,” Pete observes. “It brings down the prove-out time.

Most people are visual learners. If you can see the simulation happen, you’re probably a bit more confident in what you’re doing.”

Pete’s confidence in the platform’s future is unequivocal: “We’ve got every confidence we’ll be using Mastercam 10 years from now, 20 years from now, hopefully. The way they’re developing the software is keeping up with the times, and the ease of training new operatives and programmers to use it is crucial for us.”