These state-of-the-art pieces of machinery can be found in almost every industry, from automotive to aerospace and power generation. Portal machines offer high-speed, high-rigidity, and high-accuracy machining. Other kinematic machine tool variants cannot offer all three of the aforementioned aspects in a single machine tool.

Basically, a portal machine is a gantry that is secured on two columns or walls. In some machines, it is the gantry that moves and in others, the gantry is fixed and the table moves underneath it. At least two axes are located on the gantry, the Y and the Z, and in the moving gantry machine the X-axis as well. Depending on the size and type of the machine, two or three additional axes can be added to the machine. If the workpiece is relatively small, it is more convenient to move the part. So, there would be one or two axes on the table manipulating the workpiece and the 3-axis cartesian mechanism moving above it. As the workpiece gets larger, manipulating it becomes more difficult, so we go with a different approach and try to place the part on a solid table and have the gantry with the additional rotary axes moving above it.

Basically, a portal machine is a gantry that is secured on two columns or walls. In some machines, it is the gantry that moves and in others, the gantry is fixed and the table moves underneath it. At least two axes are located on the gantry, the Y and the Z, and in the moving gantry machine the X-axis as well. Depending on the size and type of the machine, two or three additional axes can be added to the machine. If the workpiece is relatively small, it is more convenient to move the part. So, there would be one or two axes on the table manipulating the workpiece and the 3-axis cartesian mechanism moving above it. As the workpiece gets larger, manipulating it becomes more difficult, so we go with a different approach and try to place the part on a solid table and have the gantry with the additional rotary axes moving above it.

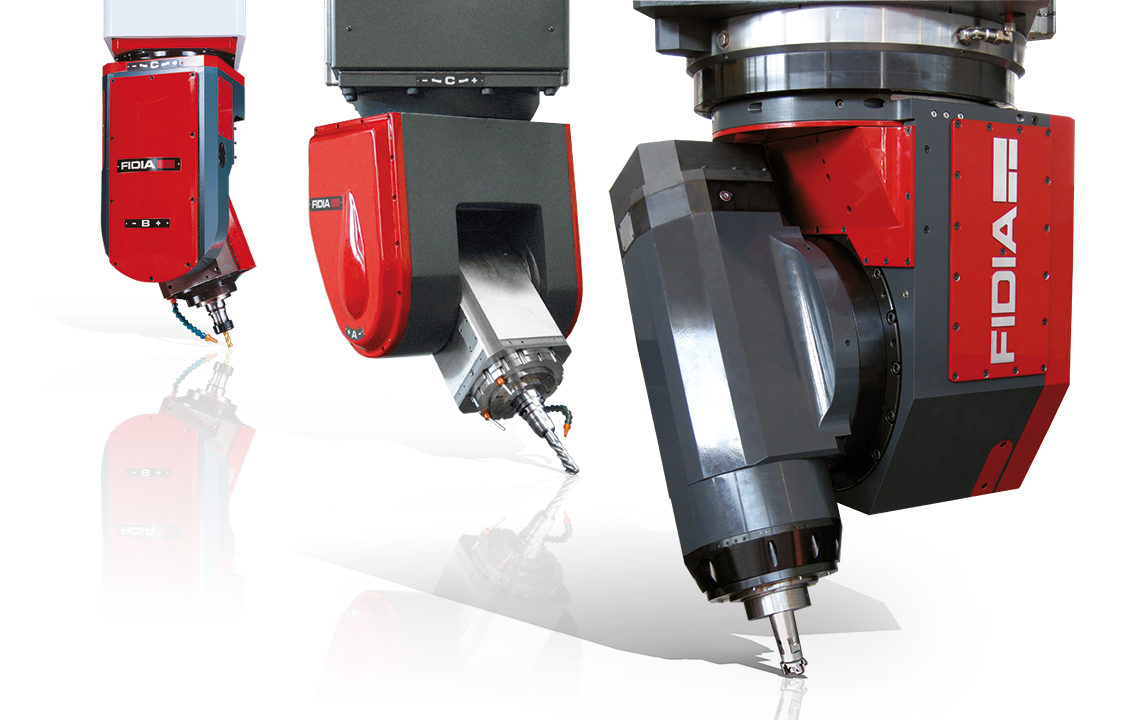

The most common way to do this is by introducing bi-axis or 5-axis heads. These portal milling machines can be categorised in many different ways, but I’d like to divide them into three main groups simply using their size. Small Portal, Medium Portal and Large Portal

The most common way to do this is by introducing bi-axis or 5-axis heads. These portal milling machines can be categorised in many different ways, but I’d like to divide them into three main groups simply using their size. Small Portal, Medium Portal and Large Portal

The Small Portal: I categorise a portal machine as small when the workpiece envelope doesn’t exceed 1000mm cube. There are different kinematic combinations available for small portals, but the majority of them have a 3-axis gantry where the X, Y and Z axes are located and there is a trunnion table rotating the workpiece underneath the gantry. There are quite a few vendors that are capable of producing amazing machines in this category such as Chiron, Edel, Hermle, Breton, Yasda, HAAS, DMG MORI and Fidia. The small category is a machine of choice in the aerospace and medical industry sectors. Thanks to the gantry structure, the rigidity of the portal machine is often higher than the moving column machine, (and of course the conventional C-type CNC frames). This higher rigidity means portal machines are more capable of machining at higher speeds. For instance, blade milling for a jet engine is often done by a 5-axis portal. Another area where the small portals excel is the medical industry. Some examples of these applications include replacing joints such as the knee, hip, shoulder and even fixing brackets for ribs. Dentists use this application for various types of tooth implants. It is fair to say those small portals are some of the most rigid high-speed machines on the market today. With a compact footprint, small portals normally don’t require a special machine bed and are often shipped in one piece. The majority of these machines use linear guideways and ball screws. As high-speed machining (HSM) strategies are becoming more popular, the need for higher speeds is increasing, therefore linear motors can be found in the latest product designs.

The Medium Portal: These portals are the most common and are produced almost everywhere around the globe. There are many manufacturers in Europe, the US, Japan, China, Taiwan and Korea. I categorise a machine as a ‘medium-sized’ portal when the distance between two columns or walls of the gantry is from 1500mm to 3500mm. The machine length can be up to 30 meters or more as a result of ‘machine base modularity’ where the modular unit is the length and this is only restricted by the space available. So, the key limiting element is the distance between the columns. These machines are integral in almost every industry, the most notable being the automotive, aerospace and oil and gas sectors.

In the automotive industry, medium size portals are used for mould and die applications. Most aircraft bodies are milled with this range of portal machine. In the oil and gas industry, they are used for valve and pipe machining. Generally, these machines are expensive, therefore the purchaser of this type of machine would require additional flexibility for multiple applications. This is the reason we would often install multiple heads and an additional carousel type rotary table to give a diversity of machining options. For example, by having a carousel table and a turning tool head that can be replaced along with the main spindle, the ability to use the machine like a vertical lathe is then possible.

In the automotive industry, medium size portals are used for mould and die applications. Most aircraft bodies are milled with this range of portal machine. In the oil and gas industry, they are used for valve and pipe machining. Generally, these machines are expensive, therefore the purchaser of this type of machine would require additional flexibility for multiple applications. This is the reason we would often install multiple heads and an additional carousel type rotary table to give a diversity of machining options. For example, by having a carousel table and a turning tool head that can be replaced along with the main spindle, the ability to use the machine like a vertical lathe is then possible.

In addition to a vertical milling head, a horizontal milling head, a 5-axis head, a grinding head and perhaps even a long-nosed vertical head can be added. Some well-known companies that manufacture this type of machine are Fidia, Breton, Promac, F.P.T, Parpas, Fives, DMG MORI, F-Zimmermann, Soraluce, Correa, Zayer, Unisign, Ken and Okuma. This size of portal is usually sold using a linear guideway moving system. The propelling mechanism is usually a rack & pinion with a dual servo motor for backlash elimination, but ball screws can also be found in machines of this size. In recent years, linear motors are being used for HSM to provide higher accuracy and better longevity.

The Large Portal: These monstrous beasts are very rare, but they are essential for any large-scale industry. Similar to the medium size machines, the large variants are also capable of many machining operations, such as milling, turning, boring and grinding. Obviously, these operations can be done in many machining positions according to the machine kinematics. The large portals normally have a moving bridge that goes up and down to increase the Z-axis stroke without risking over-extension of the Z-axis ram from its support unit. To have a long vertical reach, the bridge moves up and down and can have 2 to 8m of stroke which is often called the ‘W-axis’.

The Large Portal: These monstrous beasts are very rare, but they are essential for any large-scale industry. Similar to the medium size machines, the large variants are also capable of many machining operations, such as milling, turning, boring and grinding. Obviously, these operations can be done in many machining positions according to the machine kinematics. The large portals normally have a moving bridge that goes up and down to increase the Z-axis stroke without risking over-extension of the Z-axis ram from its support unit. To have a long vertical reach, the bridge moves up and down and can have 2 to 8m of stroke which is often called the ‘W-axis’.

The Z-axis ram which is placed on the bridge is often a square (in some cases a Hexagon, for example on the Unisign machines) which is supported by hydrostatic guideways with a maximum allowable stroke of 2.5m. To go beyond 2.5m increases the chance of chattering enormously. This shows the importance of the W-axis. The distance between the columns of a large portal can currently be up to 17m, and it is clear that the length could be much longer due to the modular design of large portals. There is no limit of machining for a large portal, (other than space and physics!) and the applications are numerous, such as the oil & gas industry, aerospace, ship manufacturing, railways and automotive. The largest I have seen had a length of 48m and it was being used in the oil and gas sector. However, I understand that Ingersoll, has manufactured machines over 100m in length. Machining large engine blocks for the ship building industry is a process that can often be conducted by a large portal machine. The workpiece can weigh hundreds of tons. Therefore, these machines require a very rigid base that may take months to dig and prepare before the machine is installed. Due to required rigidity and size limitations of ball screws, most of these machines use rack & pinion drive systems that combine with hydrostatic guideways to ensure the highest accuracy and minimum vibration. Some well-known companies that manufacture large portals are Pietro Carnaghi (available from ETG), Pama, F.P.T., Innse Berardi, Waldrich Coburg, Droop+Rein, Soraluce, Unisign and Ingersoll.

In summary, portal machines are a huge part of the machine tool world and whether they are small, medium or large, they have a vast range of applications. Many aspects and parameters need to be considered. Each manufacturer may be an expert, but this is generally in just a few application areas.When considering such an important investment, it is crucial to understand which supplier is suitable for your specific application.

In summary, portal machines are a huge part of the machine tool world and whether they are small, medium or large, they have a vast range of applications. Many aspects and parameters need to be considered. Each manufacturer may be an expert, but this is generally in just a few application areas.When considering such an important investment, it is crucial to understand which supplier is suitable for your specific application.

To repeat, no single manufacturer will be the best for all applications. When choosing a machine supplier, set out your requirements and be clear how you assess the importance of each aspect – failure to do this can lead to costly mistakes. It’s not just the initial capital outlay for the machine, what about the ‘life cycle cost?’ Serviceability, availability and cost are also important. Sometimes two machines have the same price tag, one may be European, the other Taiwanese. Whilst they may seem similar, in reality there could be huge differences. What is clear is that the European’s aren’t the only pioneers in this industry. Yes, for some large-scale machines, Waldrich Coburg and Pietro Carnaghi don’t have many competitors, but bear in mind that these machines aren’t always required as a mid-size portal. So finally, make sure that you buy a machine based on ‘Value for Money’, having fully assessed the total cost of ownership (TCO), and not just the price tag!