ESL Engineers Ltd is an AS: 9100 and ISO: 9001 accredited aerospace engineering company based in the UK, specialising in the production of critical components for major platforms like Eurofighter, Airbus, and BAE Systems. With over 60 advanced CNC machines, the company machines over 375 aerospace component types annually, leveraging its core capabilities in mill/turn, turning, milling, and gear cutting.

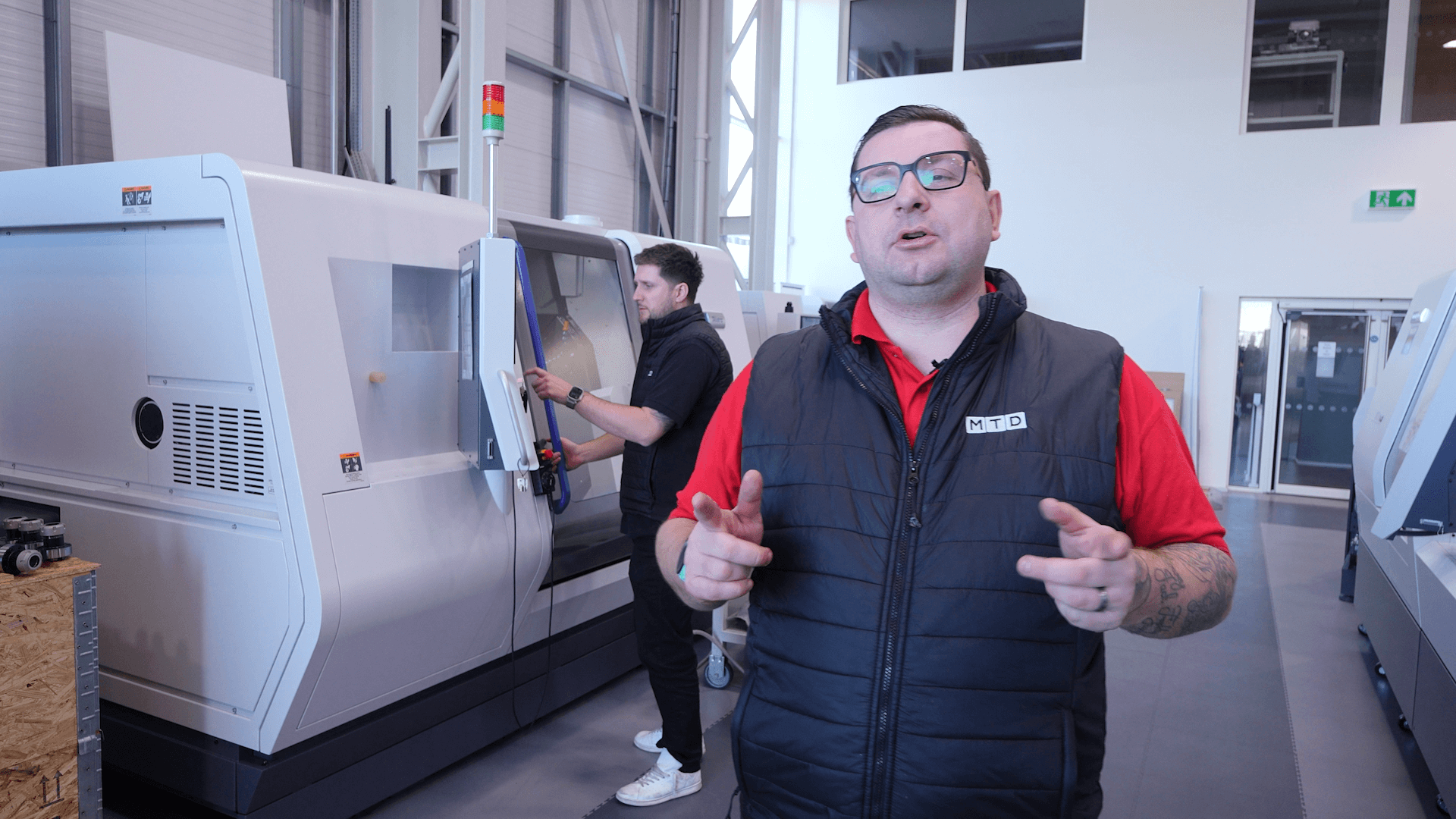

To maintain its stringent quality standards and meet the demanding requirements of the aerospace industry, Basildon-based ESL previously relied on a variety of coolant and lubricant products from different suppliers. However, the company recognised the need for a more streamlined and optimised fluid management strategy. “We had all different types of products, coolant, lubricant products, in the machine shop with different aerospace approvals,” explained Darren Perry from ESL. “We were looking for one supplier, one coolant source, one product.”

Seeking a Comprehensive

Fluid Management Solution

ESL’s search for a single, high-performance fluid supplier led them to Fuchs Lubricants, a leader in the development and manufacture of specialised lubricants and fluids. “We reached out to Darren at ESL,” said Ryan McCoy, a Territory Sales Manager at Fuchs. “We had conducted some previous work with them in the past with some older formulation technology, but I reached out to Darren when our new product Eco Core Globe 1000 got all the relevant accreditations for the Airbus specifications.”

The Eco Core Globe 1000 is a cutting-edge metalworking fluid that combines advanced lubrication technology with comprehensive environmental and safety credentials. “The main reason for choosing Eco Core Globe 1000 is obviously to do with the aerospace accreditations,” explained Ryan. “We needed to make sure that we adhered to the Airbus specification that they were looking for. ESL does much work with Airbus, so we need to make sure that the product that we supplied has the relevant accreditations, and also it provides them with a performance benefit as well.”

Rigorous Product

Evaluation and Approval

To ensure the Eco Core Globe 1000 met ESL’s exacting standards, Fuchs proposed a comprehensive 12-week trial period. “We then provide a barrel, initially on an FOC purposes for the trial,” said Ryan. “Run that on a course for 12 weeks where we’d come to the site once per week, we manage the concentration, the pH, the bacteria and the temperature control, ensuring that we take a 100ml sample each week, and send it to our labs to check the chemical makeup of the product and ensure that it’s sustainable.”

The successful trial of the Eco Core Globe 1000 at ESL’s facility yielded impressive results, with the company experiencing significant improvements in productivity and tool life. “The outcome of the trial was very successful,” Darren noted.

“It gave us a very high performance and lubricity with a tool life increase. We produce about 100 Airbus components weekly, and we were finding every day, we were getting another component from our tool life using the Fuchs products.” The enhanced lubricity and performance of the Eco Core Globe 1000 played a crucial role in these productivity gains. “The main reason for choosing Eco Core Globe 1000 is obviously to do with the aerospace accreditations,” explained Ryan. “We needed to make sure that we adhered to the Airbus specification that they were looking for.”

“ESL does a lot of work with Airbus, so we need to make sure that the product that we supplied has the relevant accreditations and also provides a performance benefit as well.”

Addressing Modern Challenges

The Eco Core Globe 1000 not only delivers superior performance and productivity benefits, but it also addresses the growing emphasis on environmental sustainability and worker safety in the aerospace industry. “It’s a high-performance product with great lubricity, which produces excellent tool life and ticks the boxes as a modern technology, health and safety, environmental product,” Darren explained.

The product’s advanced formulation and comprehensive approvals ensure that it meets the latest environmental and safety regulations while also providing the high-level performance required for critical aerospace components. “We needed to make sure that we adhered to the Airbus specification that they were looking for,” said Ryan. “ESL does a lot of work with Airbus, so we need to make sure that the product that we supplied has the relevant accreditations, and also it provides them with a performance benefit as well.”