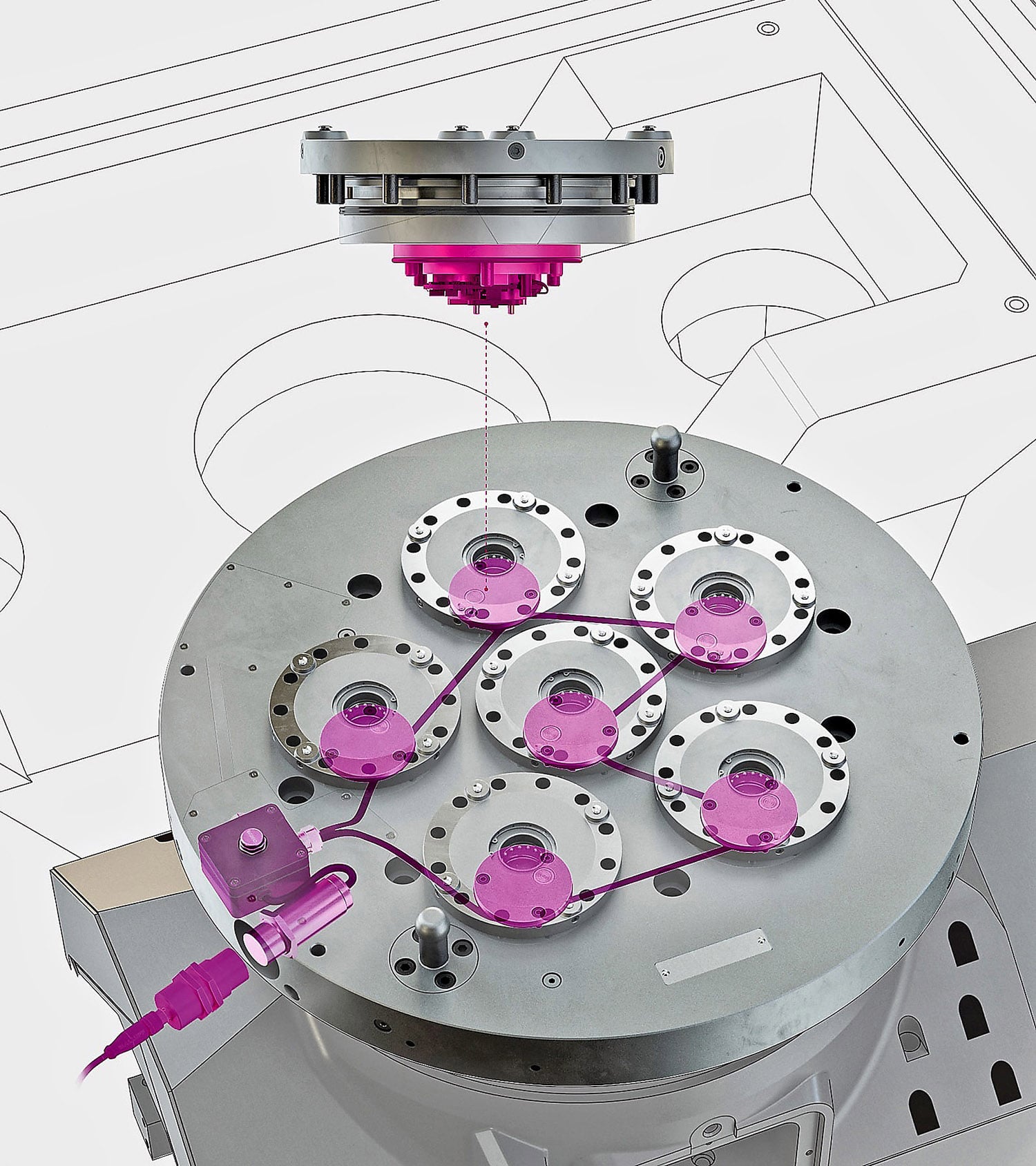

In Hall 6 on Stand 450, Roemheld will give a UK debut to a new, modular, sensor-based system that digitalises zero-point clamping by enabling digital recording of its status. STARK.intelligence enables data on workpiece loading and unloading to be integrated directly into an automated manufacturing process. Information is also provided on the condition of the clamping equipment to facilitate its scheduled maintenance.

Each fixture is equipped with its sensor box to measure position, temperature and pressure in real-time. A master unit receives data from several units and outputs the information to different devices via an IO-Link. STARK.intelligence can be combined with various STARK zero-point clamping systems and may be retrofitted easily to machine tables and quick-release fixture plates. Due to the modular design, users can choose between individual components or a complete solution, which may include the integration of an RFID interface that automatically detects pallets and workpieces.

Another introduction at the show will be a range of compact bore clamps with a large clamping range for five-sided machining. The devices hold internally, exerting force both radially outwards and downwards against a support surface. The new models enable safe location in bores from 5.2mm to 13.7mm, so are suitable for clamping small workpieces. The support height is also easily adjustable to suit workpieces having clamping surfaces at different levels. An air blast helps to keep the bushing clean and ensures reliable operation.

A third innovation will be a compact flat lever clamp designed for use on fixtures in machine tools with low-pressure hydraulics between 70 and 120 bar. It complements the successful Roemheld series rated at up to 250 bar. The hydraulic, double-acting element is suitable for mounting in any position. There are built-in and block-type varieties as well as versions without a housing for installation in restricted spaces.

Due to the flat clamping levers, even surfaces only a few millimetres above the clamping level can be machined without any problems. Depending on the operating pressure and lever length, clamping forces of up to 33kN are possible.

Roemheld will also show two models from its large range of machine vices. Most flexible is the Hilma VarioLine, which is used vertically or horizontally and may be quickly adapted to different workpiece sizes due to magnetically-secured, quick-change jaws that can be exchanged in a single action. They can be individually configured using various parameters to adapt them to different machines and applications. The other vice will be the Hilma MC-P, intended for securing parts during 5-axis machining.