ND Precision Products takes advantage of real-time information with status boards

ND Precision Products takes advantage of real-time information with status boards

With a mission to deliver precise, high-quality and complex tooling to its customers, ND Precision Products (NDPP), a long-term user of PSL Datatrack production control software has continued to invest in customised PSL Datatrack solutions to help achieve this goal. The latest investment has been in Status Boards, visual displays to provide real-time production flow and order fulfilment information to the shop floor.

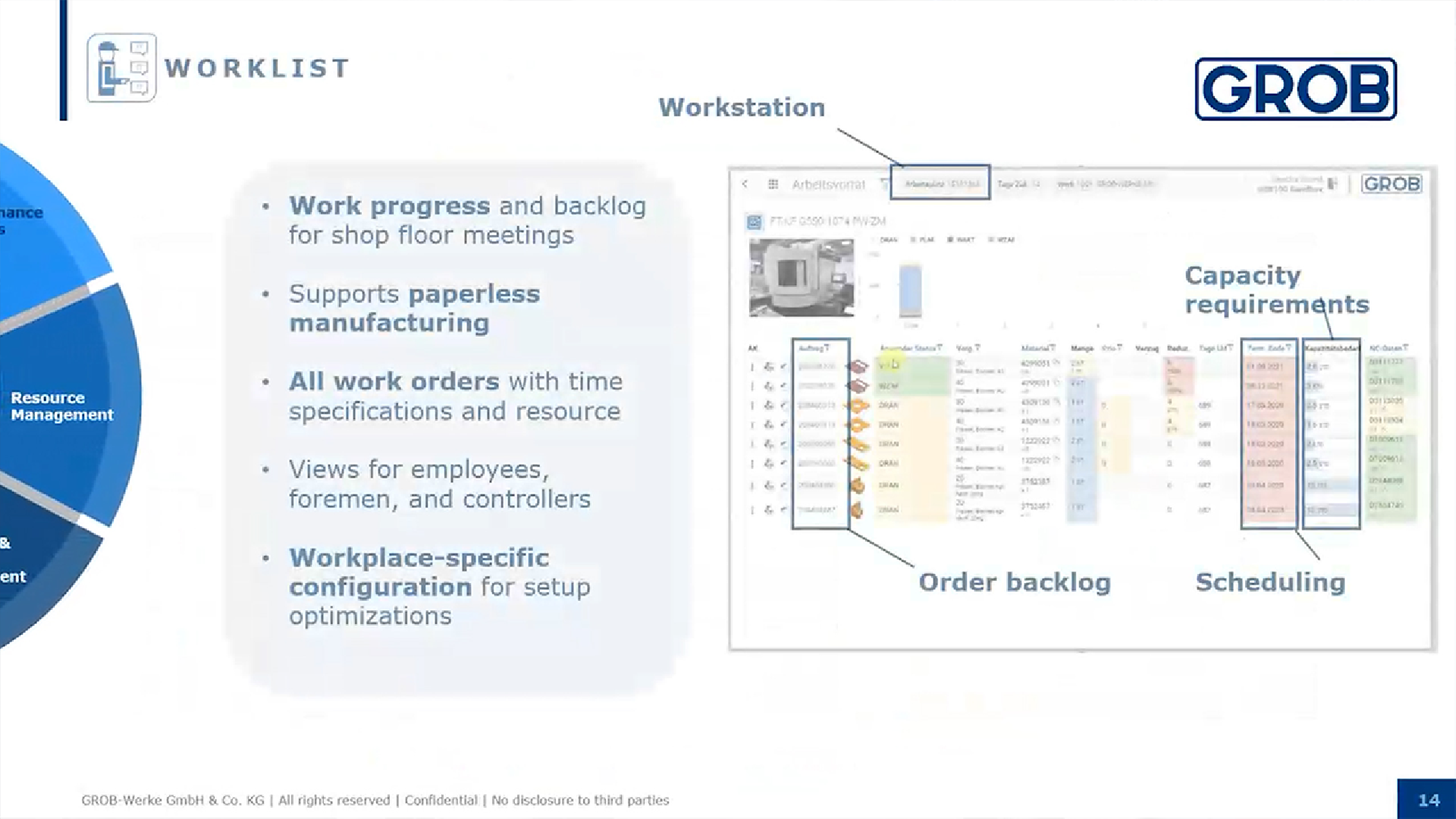

The Status Boards have been configured to NDPP’s exact requirements to give the shop floor operators clear visual data on the production status of any job. Additionally, they give management even greater control at a glance. “The Status Boards allow us to complete work in the best order, improving our efficiency and helping us to meet deadlines,” comments Nick Squire, Managing Director.

The first Status Board shows the specific job each member of the shop floor team is currently clocked on to and what stage they are at. Management can quickly check progress and make adjustments in line with business priorities, if necessary. The second Status Board shows a list of operations that still need to be conducted and when they need to be completed. This ensures on-time delivery of the order. When NDPP first acquired PSL Datatrack, it replaced inefficient manual business administration methods, including the use of emails to raise quotations – an approach that could often result in underpriced work.

This inefficiency was addressed through a series of PSL Datatrack modules, allowing the creation and administration of quotations, work orders, deliveries and invoicing to then be managed effectively. Work In Progress (WIP) and Shop Floor Data Collection (SFDC) was also implemented for order tracking and reporting capabilities for accurate costing reviews.

More areas were later identified where additional PSL Datatrack modules could make a positive impact. This included Purchase Invoicing and Scheduling, a module that validates supplier invoices against goods received to ensure that payments are made for goods at the correct price and in the correct quantities. The Scheduler module helps to manage the production flow throughout the entire factory by providing an overview of the time required to complete jobs within a given period, with ‘work to’ lists to provide shop floor staff with the optimum sequence of work through each factory resource and estimated completion reports highlighting which jobs may be late, allowing replanning and rescheduling to take place. This investment resulted in total control over the entire supply chain. NDPP could demonstrate a fully integrated administration process to customers, including fair and accurate quotations and consistent on-time deliveries with reduced lead times. The company could even forecast tooling requirements to effectively manage even the most complex of engineering jobs.

Today, the services in demand from NDPP can vary considerably depending on customer requirements, with press and mould toolmaking a particular area of expertise. Customers come from many different markets but the production control procedures that the company now has in place through PSL Datatrack, including the new Status Boards, allows them to adapt. The company was able to react successfully to demand for their engineering services from the medical sector during the Covid-19 pandemic.

“Utilisation of PSL Datatrack is very beneficial for every project we undertake. It enables us to be much more organised and we can now closely track our work from order to invoice in live time,” concludes Nick Squire. “Whenever we have a query or require customised reporting, PSL’s support team is always very helpful in suggesting solutions. Our investment over the years has suited us well and we are in a strong position for the future.”