NCMT ‘moves technology on’ for toolmaker

When BM Injection needed to upgrade its wire EDM capabilities, the company recently turned to NCMT and its Makino range of machines. Providing a total plastic injection moulding service to the aerospace, automotive, white goods, electronics, transport and PPE equipment sectors, Hampshire based BM Injection specialises in technical plastic mouldings and assemblies, supplying both thermoplastic components and thermoset moulded parts.

Commenting upon the business, BM Injection Technical Director, Mr Mark Combes says: “BM Injection are an injection mould tool maker, but we set ourselves apart because we take the customer’s initial concept and push it through to reality via toolmaking, moulding, assembly and delivery.”

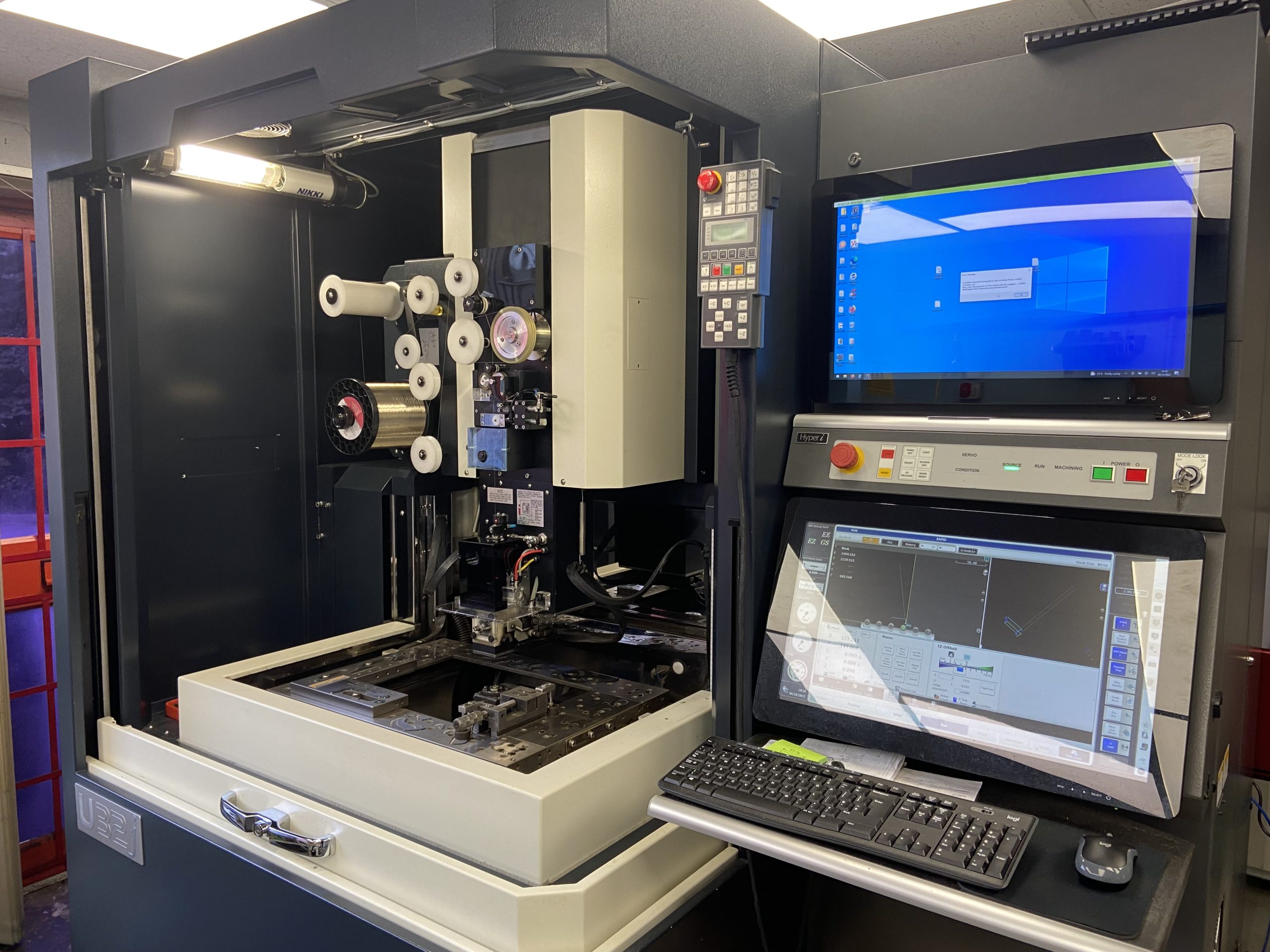

Taking a closer look at the Makino U32j high-accuracy wire EDM, Mark continues: “Within the tool-making process, every tool we make will be touched by this machine. Whether it’s for a complex geometry core, an injector pin, to an optical face that needs a very high precision finish, this machine deals with that for us. Everything is going through this machine, in one aspect or another for the mould tools that we build.”

As a direct replacement for an ageing wire EDM machine, Mark alludes to why the company opted for the Makino solution from NCMT. “The machine this Makino replaced was here for many years. We’re a very tightly packed factory, we had a requirement for a machine that fitted in the same space as our recumbent machine, but what we wanted to do was evolve our technology. So, this machine was chosen for two reasons.”

“The first reason was the floor plan was actually smaller than our previous machine, so it gave us a little bit more access. Secondly, the technology was a move on from our previous machine. So, when I talk about that technology, I talk about the speed of the cut, the programming, the computer and the finishes that we can achieve.”

The U32j at BM Injection was also specified with Makino’s Hyper i control that utilises a straightforward 3-Step operation process of Program/Setup/Run. This efficient and user-friendly interface that utilises two monitors is used for all Makino Wire and RAM EDM machines. The operator is provided with an effective and commanding view of the control with the large 24” class HD touch-screen display, and the interface delivers an intuitive and familiar touch Pinch/Swipe/Drag operation similar to smartphones and tablets. The Hyper i control is also standard with a full-function advanced hand box, digital onboard electronic manuals, instructional training videos and advanced E-Tech help functions that enable the operator to be productive.

Alluding to this system on the new Makino U32j wire EDM, Mark continues: “We specified this machine with Hyper i. So, the upper screen actually has hyperMILL and Opticam from SolidWorks loaded on. This means the user has access to all of our jobs via a database. Instead of programming offline, our operator is pulling the 3D files in, programming and then activating them on the machine. This means that everything is in one work plan, so the user is not having to ask any questions and the jobs can be up here – loaded and programmed on the machine.”

“This ensures that we’re not ‘hot desking’ for a CAM seat and we’re not saying, ‘can I use that system there?’ Every operator has got a system that they can pull jobs off and work from.”

The Makino U32j Wire EDM machine from NCMT is built to achieve high levels of precision with surface finishes down to 0.07µmRa with the Crystal II Circuit. Optionally, it can operate with wire sizes down to 50µm, making it suitable for producing high-precision plastic injection moulds, precision stamping tools, and medical component applications. Positional accuracy is accomplished through high tolerance alignment specifications that deliver axis accuracies of 3μm straightness and 4μm squareness and parallelism.

The U32j utilises a stationary 780 by 590mm worktable that eliminates the di-electrode weight shifting that occurs with travelling table designs. The space-saving design minimises the machine footprint by incorporating the di-electric reservoir into the base casting, this space reduction was a key element for BM Injection. This integrated reservoir also improves machine accuracy through greater thermal stability. The programmable rise and fall 3-sided work tank also provide excellent ergonomic access to the work zone and simplifies the loading and setup of the workpiece.

Referring to the installation process and service, Mark continues: “Installation with all our NCMT machines has been fantastic. They are very thorough, not only on positioning but on checking the accuracy of the machine from when it left NCMT to when they’ve sited it here. Concerning training, we had three days with three operators. So, from start to finish, we were really happy as always with the support that we got.”

“This is the fourth machine that we have now purchased from NCMT since 2016. We started with an Okuma Genos for our bolster milling applications. We then replaced an older CNC spark eroder with a Makino EDAF3. Just before the pandemic in 2019, we invested in the biggest machine we’ve ever had, a 5-axis Makino D200Z. The reason we keep buying machines from NCMT is the service we get. It gives us confidence that we’re not only buying a machine that gives us fantastic technology, but with the support we know we’re not going to be down for any periods longer than we need to be. Inevitably, things go wrong, but it’s how they react which is good. We get the response we need. Even if I’m not getting it done, I’m getting support to say, ‘yes we are working on your problem’. So, it’s important when you’re spending vast amounts of money on machine tools – the support needs to be as good as the machine and with NCMT, it is.”