🎧NCMT breaks the prototype barrier with Tritone AM

Additive manufacturing (AM) has long promised to transform production, but too many technologies have stalled at the prototype stage. Now, NCMT’s partnership with Tritone Technologies brings a different approach to the UK and Irish markets with MoldJet. This paste-based AM process finally makes high-yield, shop-floor-ready production a reality. MTD magazine spoke to Scott Robinson, NCMT’s Additive Sales & Application Engineer, about why this technology matters, how it works, and what it means for UK manufacturers.

Q: Scott, can you tell us more about your career journey, and how you have come to lead NCMT’s additive manufacturing drive?

Scott Robinson: I’ve been in manufacturing for over 13 years, across design, prototyping, metrology, and software. My first real step into additive was at ProtoLabs in Telford, where I helped set up their European AM operations. From there, I moved into roles across Germany and the UK, covering everything from reverse engineering to scanning, fixturing and software. That breadth gave me experience across CNC machining, laser cutting and additive, so when NCMT decided to bring Tritone’s MoldJet to the UK, it was a natural fit. I joined in July 2025 to drive this forward.

Q: Tritone AM is described as a step change in the market. What makes it different from other AM processes?

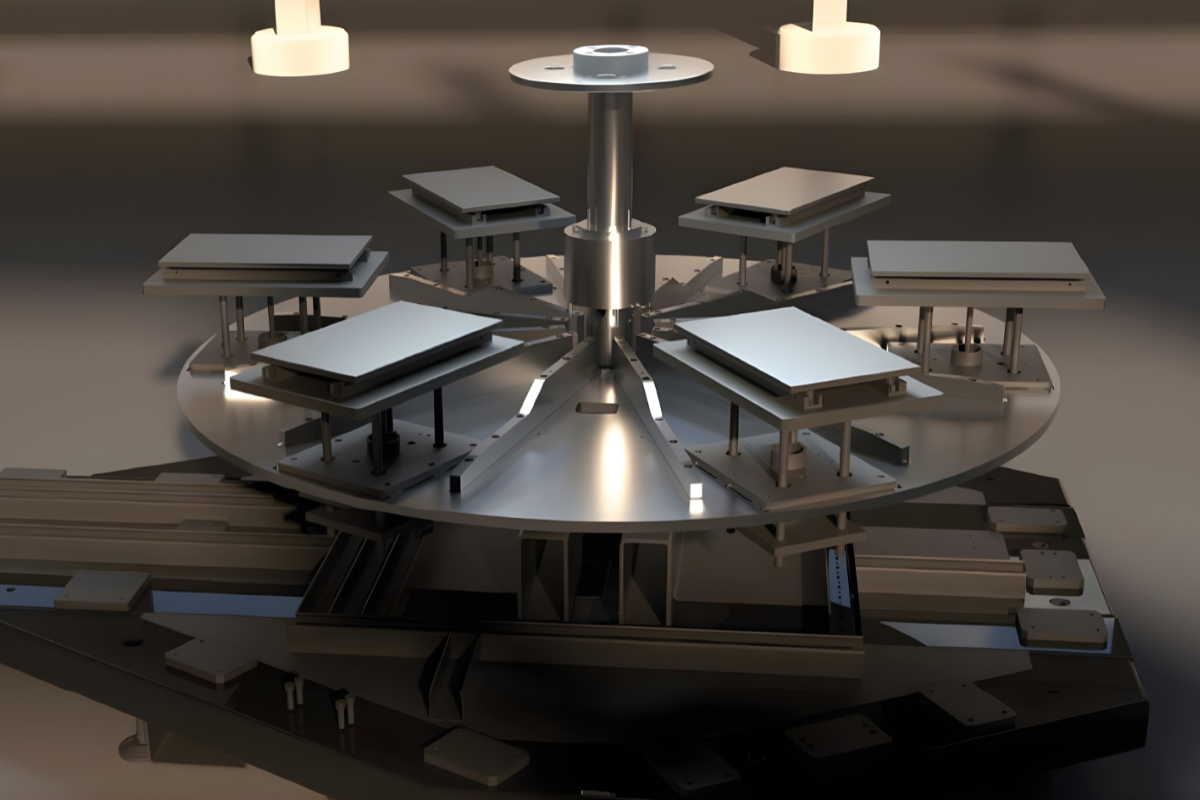

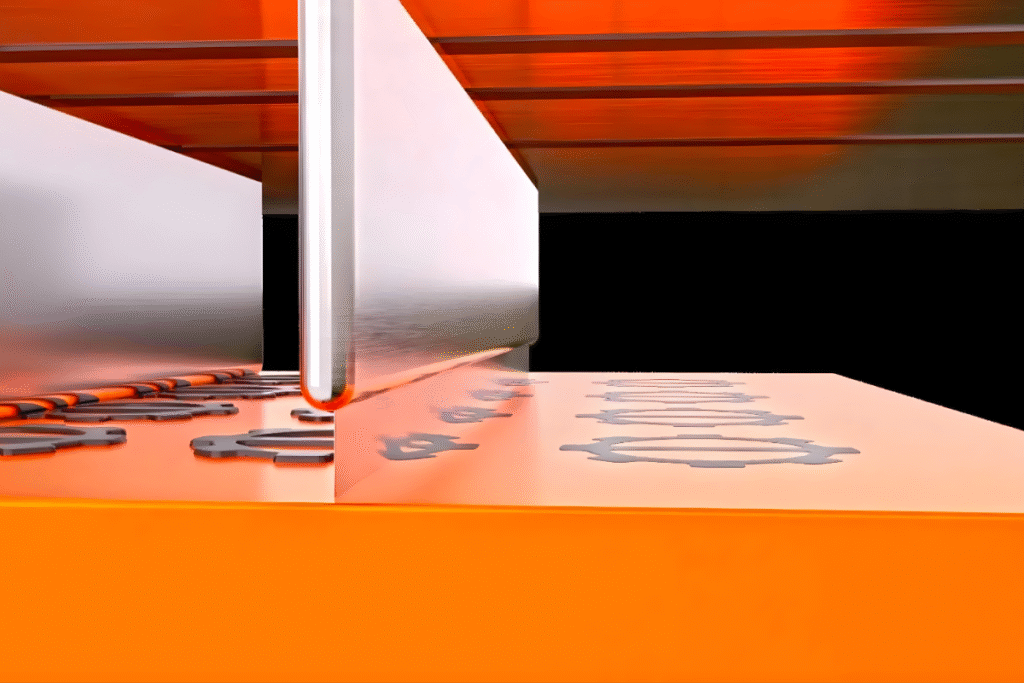

Scott: The breakthrough is that Tritone doesn’t use loose powder. Instead, it uses a metal or ceramic powder paste pre-mixed with a binder and deposited through inkjet heads into wax moulds. The machine runs on a carousel of build plates, each moving through printing, paste deposition, drying, heating and inspection stations.

Unlike powder-bed systems, Tritone can detect and correct errors in real time. If a layer is underfilled, the system re-applies material or even scrapes and reprints that layer. The result is repeatability and high yield which has always been AM’s achilles’ heel.

Q: How does this solve some of the headaches manufacturers associate with powder-based AM?

Scott: Powder-based AM can be labour-intensive and messy. After printing, you’re digging through blocks of loose powder, recovering parts, recycling unused material, and managing health and safety risks from dust or volatile powders. Tritone eliminates that. You only use the material you need for the part, the wax mould can be recycled, and your ‘green parts’ are strong enough to handle.

In practice, a technician only moves the tray from the printer to a low-temperature oven to melt away the wax, and then into a sintering furnace. It’s low touch, clean, and efficient and crucially, it fits straight onto the machine shop floor.

Q: Does MoldJet offer production-level capability or is this still a prototyping tool?

Scott: This is where Tritone really shifts the game. Traditional AM excels at prototypes or small batch runs, but Tritone bridges the gap to volume production. With multiple trays running continuously and the ability to change materials in under an hour, just like swapping cartridges in an office printer, you can move from prototype to production on the same machine.

It’s also not limited to geometry, the way conventional machining can be. Complex cooling channels, lightweight hollow forms, or integrated assemblies become possible, with simple finishing passes where needed. That makes it a genuine production tool, not a lab curiosity.

Q: What industries stand to benefit most from Tritone technology?

Scott: One of Tritone’s major strengths is how it handles materials. Instead of loose powders, it uses high-grade metal or ceramic powders pre-mixed with a binding agent to form a smooth, consistent paste. Particles are evenly distributed, and uniform density is achieved throughout the build. The result is strong, accurate ‘green’ parts that sinter to around 99.6% density, virtually equivalent to wrought metal.

Tritone supplies formulated and tested cartridges for consistent results, but because the process uses standard MIM powders, customers can also mix their own materials.

This versatility is what makes the technology so relevant across sectors. Globally, Tritone already has traction in aerospace, defence, medical tooling and consumer goods. Applications range from copper antennas for aerospace, to lightweight surgical handles, to tungsten-carbide cutting inserts. In the UK, we’re also seeing strong interest in ceramics such as alumina, zirconia and silicon carbide for high-performance applications.

Q: How does Tritone complement NCMT’s core offering?

Scott: Perfectly. Additive isn’t replacing machining, it’s complementing it. Often, Tritone can get you to a near-net shape, saving huge amounts of material and machining time. Customers can then finish critical surfaces with their CNC equipment.

For NCMT’s established base in aerospace, automotive and the medical sectors, that combination is powerful. They already know precision machining. MoldJet gives them a faster, cleaner route to complex geometries, with machining as the finishing step.

Q: Space and safety are always concerns in a production environment. How does Tritone fit onto the shop floor?

Scott: Powder based systems often need a segregated, ventilated environment and parts need to be made in an inert atmosphere. All this equipment eats into valuable factory real estate and budget – Tritone doesn’t. The footprint of the smaller DIM system is around 2 by 2m, while the larger DOMINANT is 3.2 by 3.5m. Both are fully enclosed, compact and self-contained. You need a bench for the low-temp oven and that’s about it.

That means you can place it alongside your existing CNC cells without creating a dedicated ‘powder room’ or dealing with all the auxiliary safety kit. For a machine shop, that’s a big differentiator.

Q: Tell us about NCMT’s role in supporting customers adopting this technology.

Scott: NCMT is renowned for its through-life support. We have over 40 field engineers and that same expertise is applied to Tritone customers. From application prove-out to post-installation service, it’s the NCMT pedigree customers expect.

Tritone also supports with sample parts and even contract manufacturing to help customers trial applications before investing in a machine. That partnership approach underlines why NCMT brought Tritone into the portfolio, it matches our standards for engineering excellence and customer care.

Q: Finally, what’s your message to manufacturers considering additive, or those already using powder-based systems?

Scott: Don’t think of additive as just prototyping anymore. Tritone’s MoldJet makes AM a real production proposition. Whether you’re looking to reduce material costs, explore exotic ceramics, or accelerate throughput, this technology can sit right alongside your machining capability.

And with NCMT, you’re not just buying a machine, you’re gaining a long-term engineering partner. If you’re curious, let’s start a conversation. This is the first time MoldJet is available in the UK and Ireland, and we believe it’s a genuine step forward for advanced manufacturing.