As a global metrology leader, Mitutoyo’s measuring equipment supported by the Mitutoyo Gauging Technology (MGT) division that can design, manufacture and install cost-effective, bespoke fixtures and loading systems – is a complete solution service that West Sussex based Cox Powertrain has recently taken advantage of.

In 2009, Cox Powertrain began its mission to deliver revolutionary ultra-lightweight diesel engines for the marine industry. The result was the design, development and build of the high-powered CXO300 diesel outboard engine. Having raised over £120m of private investment to bring the advanced outboard from concept to a reality and following EPA Tier 3, RCD II and IMO Tier II certification, Cox Powertrain began production of the CXO300 in May 2020.

To ensure efficient manufacture of the CXO300, Cox Powertrain built a world-class £6.7m production facility next to Brighton City Airport. Designed to deliver reliability and longevity, quality has been built into every facet of the CXO300. This all embracing quality philosophy is reflected in Cox Powertrain’s rigorous quality assurance systems. For instance, the company’s new factory was designed with a ‘no-fault-forward’ concept in mind. Each CXO300 component is fully traceable and continual checks are carried out at each stage of production to ensure that all parts adhere to specification before they move forward to subsequent workstations.

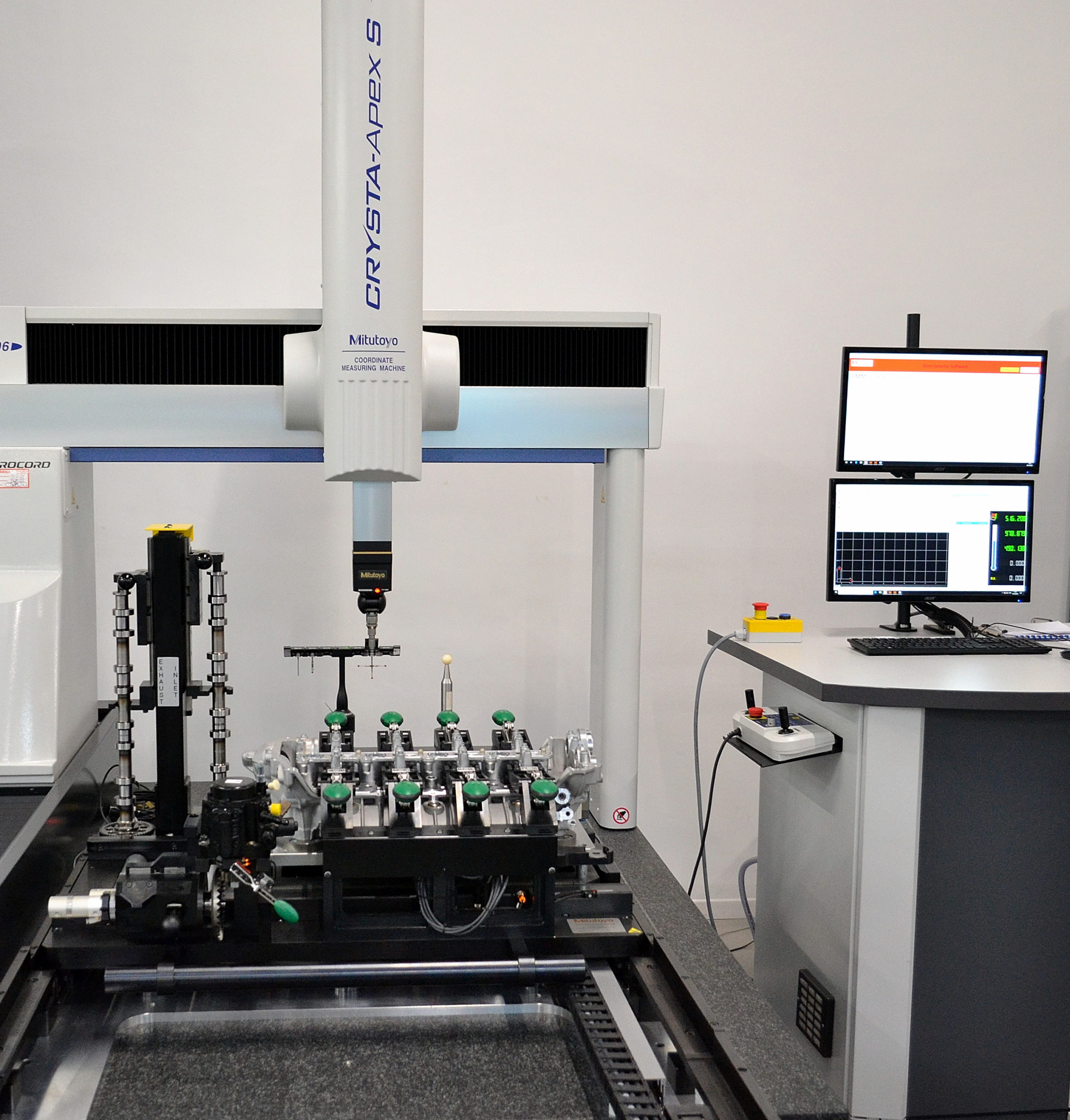

The recent installation of a Mitutoyo CRYSTA-Apex 9106 Series CMM, served by a tailor-made, highly-efficient loading and unloading fixture, reflects Cox Powertrain’s pursuit of the highest standards of quality and efficiency. The company’s advanced Mitutoyo CMM is equipped with a temperature compensation system that guarantees the accuracy of measurements under temperature conditions from 16 – 26°C. The CRYSTA-Apex temperature compensation system ensures that, in addition to having the ability to deliver accurate results, it is also able to undertake precise inspection routines within production environments, such as on Cox Powertrain’s shop-floor.

The highly efficient CRYSTA-Apex CMM offers a maximum drive speed of 519mm/s and a maximum acceleration of 2,309mm/s2. As these impressive figures are much faster than those of general-purpose CNC CMMs, CRYSTA-Apex machines are ideal for operating within high-volume production and inspection situations.

Given the large volumes of components that need to be inspected on the company’s Mitutoyo CMM, Cox Powertrain Manufacturing Engineering Manager, Tom Wheeler contacted Mitutoyo Gauging Technology (MGT) with a list of system requirements related to a proposed bespoke fixture that would enable parts to be easily and quickly loaded and unloaded to and from the CRYSTA-Apex CMM.

The MGT division of Mitutoyo UK provides a specialist service that aims to meet the increasing need for customised measurement solutions to support manufacturers’ quality assurance operations. From one-off fixtures to fully automated measurement systems, MGT can provide an answer to the simplest or the most complicated of measurement challenges. The outcome of the discussions between Tom Wheeler and the staff of MGT was the design of a loading/unloading fixture that would increase the efficiency of Cox Powertrain’s CMM.

Tom Wheeler explained: “Having considered other options, we decided the Mitutoyo CRYSTA-Apex CMM was the kind of high specification machine that had the ability to accurately and rapidly inspect our components, including those with the most demanding of dimensional tolerances. To ensure the rapid feed-back of inspection data to our assembly operations and to minimise scrap and rework levels, our new facility was designed using a highly-efficient ‘no-fault-forward’ model. Our Mitutoyo CRYSTA-Apex CMM and its bespoke loading fixture fit perfectly into this concept.”

“As it has a temperature compensation system that guarantees high-precision inspection results under shop-floor conditions, we were able to locate the CRYSTA-Apex close to our assembly lines. In addition, the CMM’s high levels of automation, speed of operation and its rapid data generating capabilities means that, if a component dimension is found to be drifting from its nominal condition, prompt interventions can be made. To further enhance the CMM’s levels of automation and efficiency, we liaised closely with the MGT staff to develop an optimal design for a bespoke loading and unloading fixture. The result was the installation of a fixture that allows multiple components to be measured within a single cycle. The fixture has significantly improved our CMM loading/unloading speeds and efficiency levels. The combination of our highly efficient CRYSTA-Apex CMM and its bespoke fixture has proven ideal for our high-precision, high-volume needs.”