🎧Mitutoyo delivers speed advantage with horizontal CMM

Advanced CMMs are becoming the cornerstone of automated production environments, where closed-loop feedback and exceptional throughput are transforming how manufacturers approach quality and efficiency. In sophisticated manufacturing cells across UK aerospace facilities, a quiet revolution is taking place.

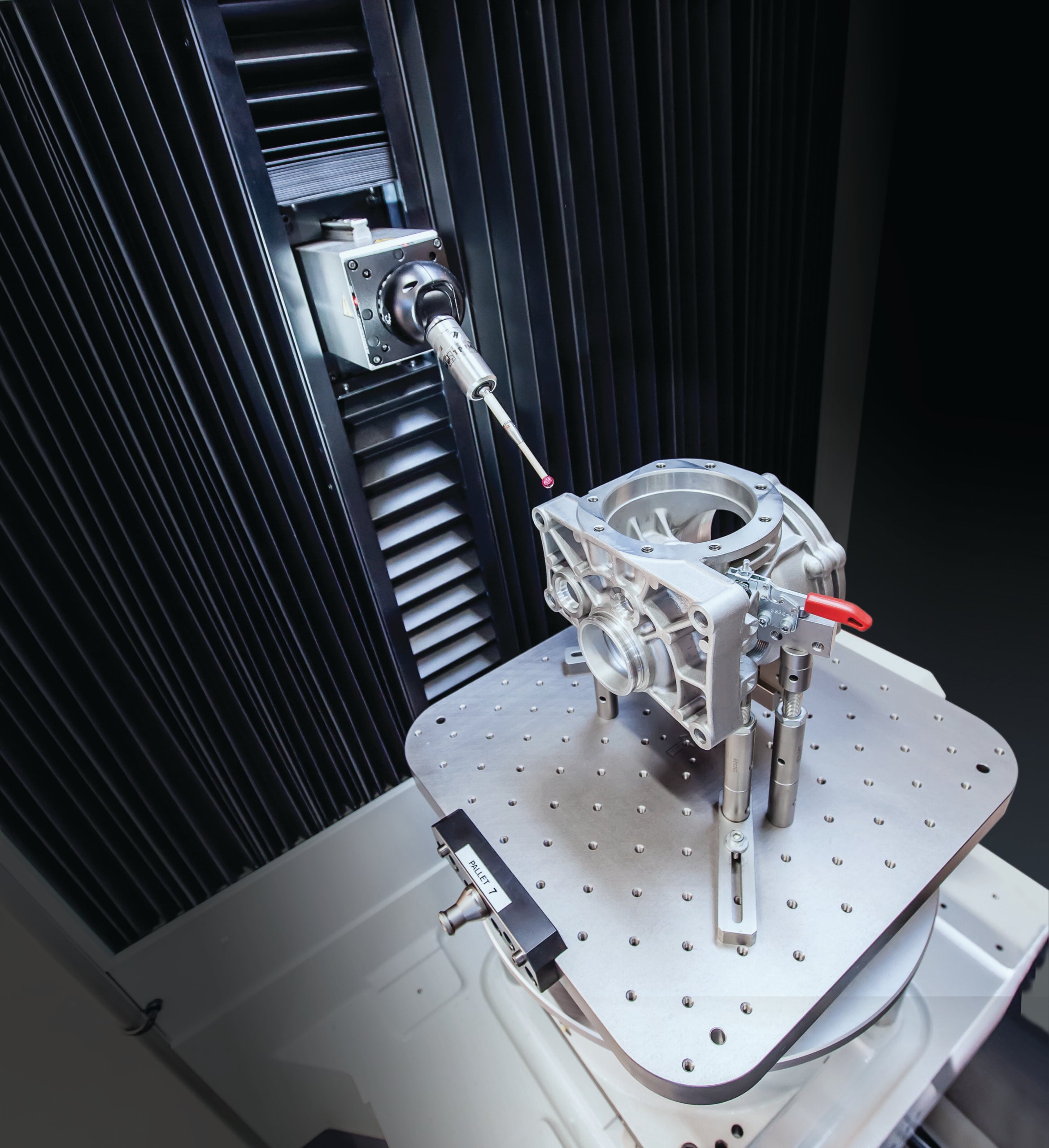

Horizontal CMMs from Mitutoyo are proving themselves indispensable in high-volume production environments as the cornerstone in ‘smart manufacturing systems’ that are fundamentally changing how parts are made.

At one of the UK’s leading aerospace OEMs, the Mitutoyo MACH-3A has become central to production operations across multiple sites. A multitude of MACH-3A machines now form the measurement backbone of automated cells producing critical engine components.

Traditionally, at the end of the production process verifying finished parts, Mitutoyo is shifting the identity of the CMM with the MACH-3A. Recent installations demonstrate a more sophisticated philosophy.

Nozzle guide vanes are static airfoils that direct combustion gases through jet engines. Critical components that start life as castings, the vanes are manufactured to tight tolerances for optimal engine efficiency. Here’s where the integration becomes elegant.

“The part actually has to come to the CMM before it goes to the machine tool,” explains Andrew Fifield, CMM Product Manager at Mitutoyo UK. “The data from the CMM goes into the machine tool to tell it what to cut based on the casting. Nothing’s flat on these parts at all—there’s no prismatic start point.”

This approach means the first cut considers the casting’s actual geometry rather than assuming an idealised form, reducing set-up and machining times whilst also optimising tool paths and strategies.

After the initial grinding operation, parts are automatically returned to the CMM for further calibration. The data points are fed to the grinding centre for secondary machining. This cycle repeats up to four times during the complete manufacturing sequence. Each measurement allows the machine tool to compensate not only for casting variation but also for tool wear, temperature changes, and material characteristics that emerge during processing.

Engineering for Extreme Throughput

The MACH-3A’s specification sheet reveals why it suits this demanding application. The horizontal-arm configuration, with its 600 by 500 by 280mm measuring range, delivers substantial capability in a footprint that fits between machine tools in a production cell. However, the headline figures lie in motion performance.

With drive speeds reaching 1,212mm/sec and a maximum combined acceleration of 11,882mm/s², the machine moves at speeds more commonly associated with machine tools than a CMM. With a measuring speed of 30mm/sec, the improvement over conventional bridge CMMs demonstrates a completely different class of performance.

A comparison with Mitutoyo’s own Crysta-Apex V544, a high-quality bridge CMM with a similar measuring volume, illustrates the difference. Where the Crysta-Apex achieves 519mm/s maximum drive speed and 2.3m/s² acceleration, the MACH-3A more than doubles the speed and increases acceleration by a factor of five.

“The real time saving comes from the acceleration,” notes Fifield. “Our bridge machines have excellent acceleration at around 2,000mm/s², but you can see this is five times that—11,000mm/s². We can typically halve the cycle time with this machine.”

When measuring a transmission case with typical features—true position measurements, internal diameters, and hole-to-hole pitches—the Crysta-Apex requires 57.6 seconds. The MACH-3A completes the same task in 24.3 seconds.

“If the CMM is slow, you end up with a bottleneck. It’s that direct connection to the throughput of the cell,” Fifield emphasises. “A typical first operation measurement programme might be seven minutes, then it goes for a five-minute grind, back to the CMM for another ten-minute operation, then a thirty-minute grind, and back for final inspection.”

Robust Design for Production

“The Z-axis is horizontal, and all of the moving elements are housed behind bellows in the back of the machine,” explains Fifield. “That provides shop floor robustness. We’re keeping everything hidden away—there are no surfaces for anything to land on. It’s all protected from the environment.”

This architecture keeps critical components away from coolant spray, metal chips, and airborne contamination that characterise production environments.

“In the back there is just a much stiffer build of machine. We’re using all mechanical bearings and powerful drives,” Fifield notes. “It’s similar to a machine tool—if you consider a moving machine, it has to be incredibly stiff to make precision cuts. We’re building more towards that.”

“The machine has a bigger temperature range—we provide an accuracy specification from 5°C to 40°C,” Fifield points out. “On a bridge machine, it’s typically 16°C to 26°C. To cope with factory environments without air conditioning or full temperature control, the design and scales have been specially designed. Using similar materials for different parts of the build helps—as soon as you’ve got different materials like granite and aluminium, compensation gets more difficult, particularly as you go into a wider temperature range.”

Precision Measurement at Production Speed

“At the speeds and accelerations we’re moving at, we need a really robust probe,” explains Fifield. “The Renishaw TP7 is the same touch-trigger technology as the TP200, but it’s more robust, so we can drive it around faster.”

The optional indexing table further enhances capability by rotating parts to optimised orientations, improving probe access to difficult features and reducing the need for multiple fixtures or setups.

From Standalone to Fully Integrated

Whilst the MACH-3A can operate as a manually loaded inspection station, its design anticipates integration with automation systems. Fifield identifies three distinct levels of automation capability: “First is standalone end-of-line inspection with our Smart Measure AL automatic loading system—parts queue in racks and the system loads them sequentially for overnight batch measurement. The next level is in an automatic cell where we machine, clean, and measure parts, with finished components dropping out at the end. Then the top level is closed-loop feedback, which is what we see at aerospace customers. We do a casting alignment, tell the machine tool where to take material off, it takes the material off, then back to the CMM for more operations. As the tool is cutting and things are wearing out, temperature is changing, the CMM provides data to make small corrections, so they don’t produce scrap.”

More sophisticated installations employ industrial robots from automation specialists, with programmable logic controllers managing communication between all cell components. These systems vary in sophistication.

Value Proposition in High-Volume Manufacturing

At approximately twice the cost of a conventional CMM with comparable measuring volume, the MACH-3A represents a significant investment. However, this must be evaluated in context.

“Floor space is a restriction,” Fifield notes. “Having machines that can go twice as quickly means you need less floor space. That’s where we’re having success—dealing with companies where they’re filling up their factories and they’re not at the point where they want to build another big factory. They want to replace slower equipment with faster machines and hopefully automate. It’s upfront investment for long-term increased throughput and returns.”

He adds a compelling example: “If you consider having to put two machines in, they don’t go right next to each other—there’s a big footprint. You’d end up having to put two bridge machines in to do what the MACH-3A can do. The footprint saving is probably better than 50% compared to two machines.”

In automated cells where production throughput depends on the slowest component, a measurement bottleneck constrains the entire system’s output. The faster CMM may cost more, but it preserves the capacity of expensive machine tools and robotic handling systems.

Addressing Multiple Sectors

“We’ve seen some success in the US medical area, and I’d really like to see us get these machines into medical companies in the UK,” Fifield states. “The big thing happening in medical at the moment is the increase in throughput and automation, so using the aerospace case study and automation as an example, I think we can make that connection to medical, and automotive as well.”

The automotive industry continues its evolution towards electric vehicles and advanced powertrains, requiring new components produced in high volumes with tight tolerances. As these manufacturers establish production lines, the integration of fast, automated measurement systems becomes a natural design choice.

The Future of In-Process Metrology

“I think the world’s shifted a bit politically, and certainly in the UK, we are bringing manufacturing back rather than going overseas,” Fifield observes. “We have high labour costs, so we’re trying to use our high-skilled engineers to produce automation systems and still produce value-for-money products by uplifting to automation and fast throughput. That’s where we’re seeing the resurgence.”

The MACH-3A installations at a leading aerospace manufacturer represent more than efficient inspection—they demonstrate a manufacturing philosophy where measurement and production form an integrated whole.

The combination of speed, accuracy across challenging temperature ranges, and comprehensive automation support positions horizontal CMM technology as an essential enabler of modern manufacturing cells. For companies producing high-value components in significant volumes, the question isn’t whether to integrate advanced metrology into production processes, but how quickly they can implement systems that their competitors may already be deploying.

In that context, the MACH-3A addresses the fundamental challenge facing UK manufacturing: producing more, faster, in less space, with higher quality and full traceability. These aren’t aspirational goals—they’re the basic requirements for competing in global markets.