In the majority of manufacturing scenarios, time (cycle time) is one of the most important parameters that directly affects a company’s element of competitiveness and profitability. However, the factor of ‘time’ is seldom a matter of life and death. Manufacturing a component can be optimised to reduce costs, but if the cycle time is too long, it probably wouldn’t end up causing amputation or death. This is not the case in the medical sector. Accidents could happen at any time and a prompt medical response is essential to save a life, an organ, or a limb. In this article, we discuss how rapid prototyping and production could help with saving lives. By Kasra Mehraky.

Ever since its introduction into mainstream manufacturing, additive manufacturing has been in demand in the biomedical industry. Nowadays, the applications of this method are no longer limited to medical research and development, the area in which it was initially used due to its rapid prototyping feature, and it has become a popular manufacturing method in several areas in the biomedical industry. Owing to the countless advantages of AM manufacturing such as flexibility, availability and cost-effectiveness, it now has a wide range of medical applications including the production of dental fixtures and jigs, hearing aids, prostheses, implants and even surgical instruments.

Advances in additive manufacturing make the production of all these components quicker, less expensive and above all customisable, making them available for a larger number of patients in need. This is especially the case in remote places and third-world nations without access to conventional expensive manufacturing equipment. The unmatched flexibility of this method allows for affordable production of customised components, making implants and prostheses matching with each individual’s anatomy and situation. This brings more comfort to the recipient. Similarly, 3D printing technology is a practical learning and diagnosis supplement for both students and surgeons, since it can be used to provide realistic models of any patient’s organs. This way it’s possible for doctors to do a more extensive analysis of the patient’s condition before surgery, aiming to reduce the risk and duration of the operation.

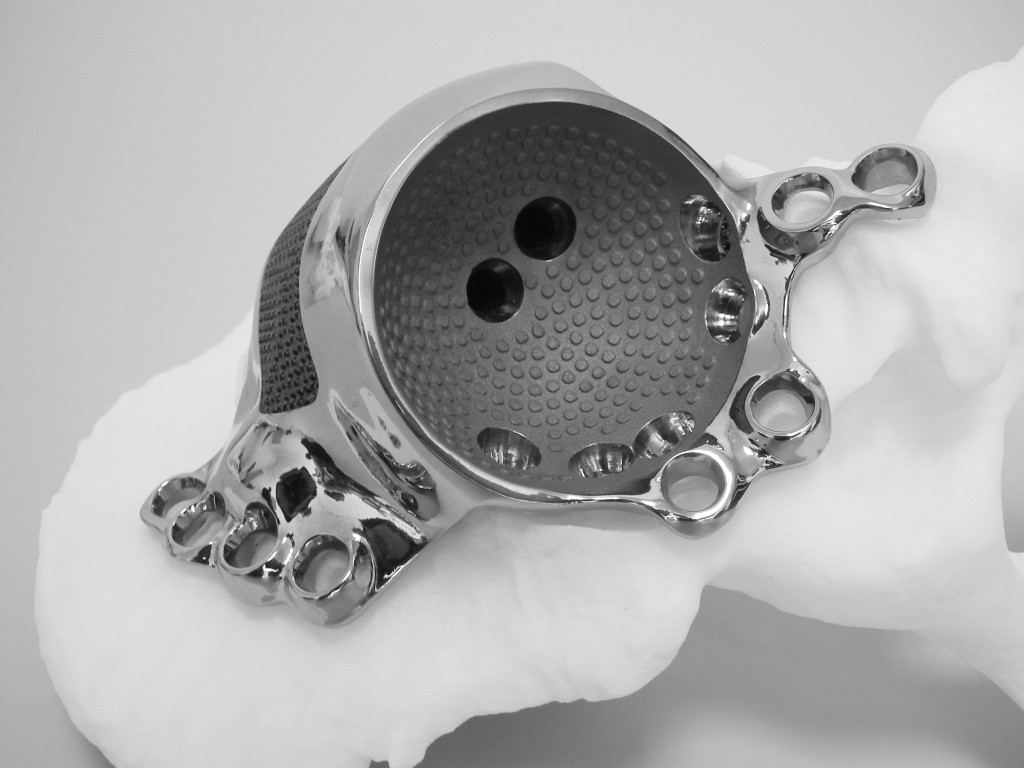

The emergence of additive manufacturing in the biomedical industry has especially contributed to manufacturing metal implants and orthopaedics science. Using this technology, numerous parts of the skeleton can be replaced, ranging from knee joints and ankle bones to acetabular cups and parts of the skull.

Among the metals frequently used for manufacturing implants, titanium and cobalt chrome alloys are the most common. The mechanical properties of titanium such as strength, low density, corrosion resistance and non-reactivity have earned it the title of the most biocompatible metal. For this reason, cranial plates, dental implants and small joint implants are often made out of titanium. Cobalt chrome alloys are similar to titanium in terms of biocompatibility but offer additional strength and hardness, making them the main material for heavy joint replacements in the knees, hips and shoulders. In addition to the great number of advantages of using additive manufacturing for implant manufacturing, using this method with titanium has the added benefit of making the reduction of elastic modulus of porous titanium possible. This way the elasticity mismatch between the implant and the human bone can be almost eliminated, reducing stress shielding and ultimate reduction of bone density.

The foremost advantage of metal additive manufacturing over other manufacturing methods for biomedical applications is the production of affordable bespoke components. Customised implants produced according to each person’s size and anatomy help to achieve maximum contact and stability, resulting in a shorter recovery period, improved healing, adaptability and chance of success. Among the many real-life examples of this are ribcage implant surgery, successfully performed in several countries, and the replacement surgery of a talus bone of a patient with a 3D printed titanium implant, without which the patient’s ability to move the foot would be lost.

Another improvement in metal implant manufacturing made possible by metal 3D printing is the facilitated production of geometrically complex and lightweight implants. Typologically optimised implants can be manufactured using data from standard medical imaging, which would alternatively require meticulous design and calculations using machining or other conventional methods. Even so, some shapes are impossible to produce or require time-consuming and complicated tooling to manufacture with machining. Needless to say, this feature of AM contributes to the duration of healing and the chance of success.

Moreover, using bespoke implants can in many cases eliminate the necessity for follow-up removal and/or correction surgery due to implant migration, breakage or rejection. One exemplary case is the surgery to correct degenerative cervical spine condition, in the process of which the trabecular bone is replaced. A meticulously manufactured titanium implant fuses with the surrounding structures more easily, making subsequent bone graft surgeries non-essential.

Furthermore, the flexibility, ease and cost-efficiency of metal implant manufacturing made possible by AM technology accelerates product development and results in a shorter time to market. This can in many cases save a life.

With all this in mind, it is important to clarify that additive manufacturing is rarely the final stage of metal implant manufacturing. Since cell behaviour is strongly affected by surface properties, achieving ideal surface roughness induces better cell response and reduces the chance of rejection. Therefore, machining is often used as a post-production process for finishing and support removal. This way, each technology is used where it brings the greatest benefit. Interestingly, hybrid machines are one of the most recent advances in manufacturing that combine 3D printing and machining for this type of purpose. Such machines can further reduce production time, cost and time to market.

In conclusion, additive manufacturing technology has become an efficient option for manufacturing implants, medical devices and organ models. Due to its many benefits including affordability, flexibility and availability, it is now widely used for production in many biomedical areas, especially for metal implants. Additive manufacturing is most effective when combined with precision machining, as the former makes quick and cost-effective production of customisable implants from medical imaging data possible, and the latter ensures a successful surgery by achieving the desired surface quality and roughness.