Merc Aerospace is a world-class engineering company with over 40 years in the aerospace and defence, industries. The Lancashire-based manufacturer has a client list that includes brands such as Airbus, BAE Systems, Leonardo, Bombardier, GKN and Spirit Aerosystems. To meet the requirements of these heavyweights, the 50 employee manufacturer works with the Hoffmann Group.

Emphasising the importance of the relationship with Hoffmann, Richard Meade the Managing Director of Merc Aerospace says: “Our customers require quality, excellence and delivery from us every day. To achieve that, we place a real focus on standardising our workplace and making sure that we have everything we need – and Hoffmann has been a big part of that journey. As one of our main technical partners, Hoffmann has helped to facilitate our continuous improvement strategy, our 5S methodology, and the tooling strategy. They have been a big part of how we have improved the running of our day-to-day business.”

Looking at how the relationship has evolved, Richard adds: “When we started working with Hoffmann 15 years ago, they started by catering for our cutting tool requirements. This has evolved to vending and 5S solutions, and health and safety equipment and now we’re looking at the connected manufacturing offering. Hoffmann are constantly developing new products and the product catalogue continues to evolve.”

Richard adds: “Cost savings are a big focus for our business. The solutions that Hoffmann has provided have certainly underpinned those savings. We will continue to work with them to highlight new areas for development and we are seeing tremendous cost savings, which is enabling that reinvestment to go back into the business.”

Paul Walker, Applications Engineer for the Hoffmann Group says: “Merc have implemented the Hoffmann Group’s hand tools, metrology, cutting tools – the whole works. We have constantly developed new products, and Merc has been a great testbed for our new product developments. This ambitious combination has delivered some incredible savings.”

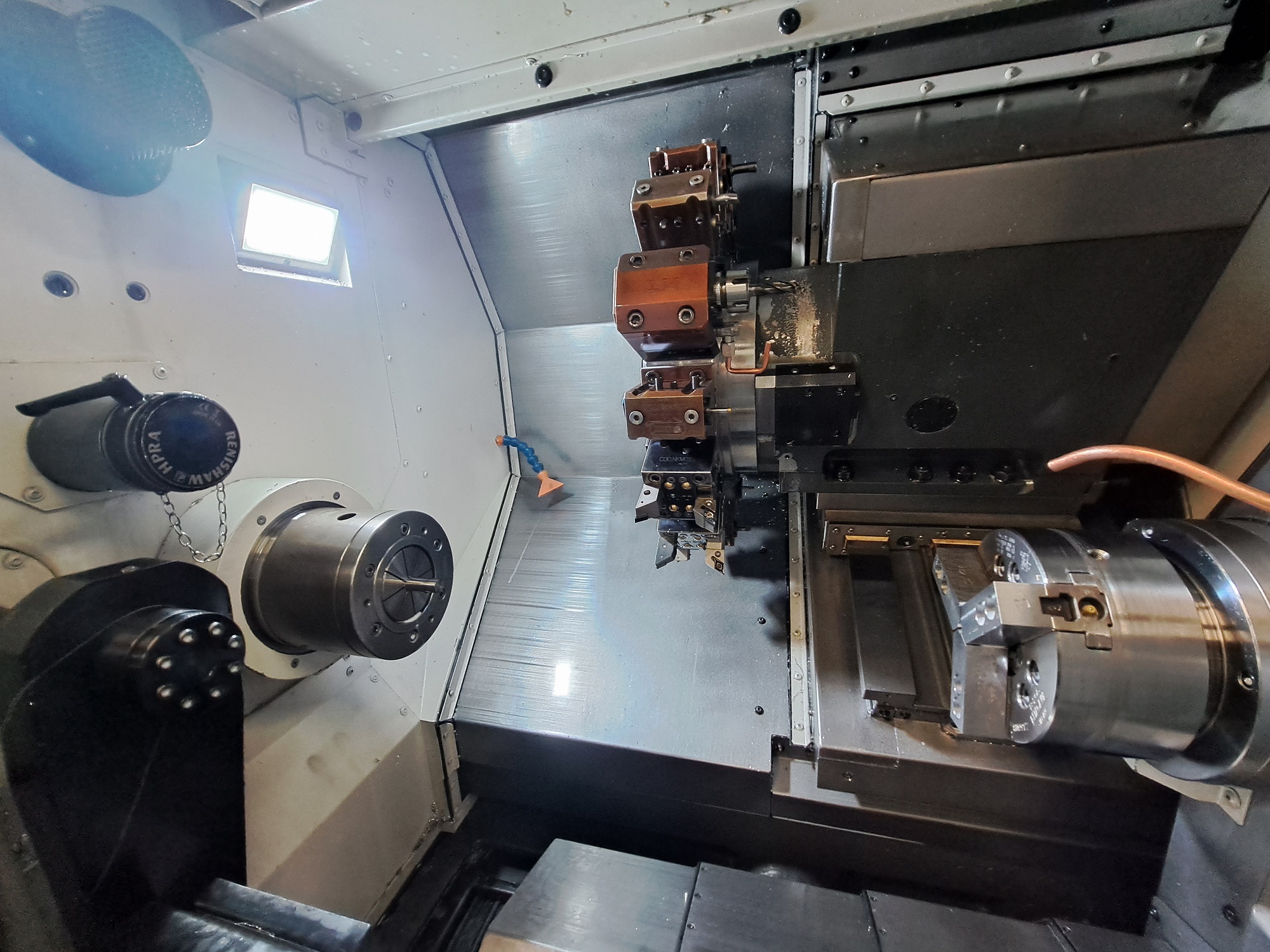

Looking at a specific application on a Nakamura-Tome WT150II turning centre, Paul continues: “Merc is machining HAYNES-230, a material similar to Hastelloy X. The process was a 12XD drilled hole at 9.6mm diameter. The tool remains stationary in this process, which is challenging for any carbide tool, so conditions had to be right for the process to work. By switching to a Hoffmann tool, we saved something in the region of £40,000.”

“The savings came from several factors. Firstly, there was a time saving where we were able to increase the feed rate by a third, but the main saving came from tool life improvements. The changeover took productivity from 20 to 161 parts. For any customer, it is important to know what the benchmark is concerning costs, productivity, hourly rate and other factors. It enables companies to work out the cost per part.”

Another recent example of cost reductions implemented by Hoffmann has been identified on the Pendle-based company’s Matsuura MX330 machining centre. Alluding to this, Paul continues: “We identified savings on a stainless steel component. Once again, we were able to save on cycle time by taking the process from a typical 3-axis VMC to the 5-axis Matsuura – a machine with high coolant pressure. This enabled us to utilise the Hoffmann through coolant Master Steel Feed Drill. The benchmark was two parts per drill. We managed to save five minutes on the cycle time. As for the tool life – it just went on and on and on. The same tool ended up being on the machine for more than five years. We calculated that in those five years, the Master Steel Feed Drill would have achieved approximately a £100,000 saving.”

As well as the cost and tool life savings achieved at Merc, Hoffmann identified efficiencies to drive employee efficiency. Discussing this, Jordan Scott from Hoffmann takes a look at one of the company’s many rolling workstations: “Not only do we have all the tools correctly located for ease-of-use; we also have standard and bespoke foam enclosures in each drawer to ensure every tool has its position. We have also supplied cleaning stations and these can be bespoke to the area or application.”

Mentioning the tool and equipment storage stations, Merc Aerospace Managing Director Richard says: “It is very easy to order everything through the Hoffmann e-shop. All of the furniture is easily available there. With regard to the foam inlays we use, there is a software system available that we use, that allows us to drag and drop, and within minutes we have specialist foam inlays that we can standardise to embed our 5S principles to the workplace.”