MTDCNC recently visited YMT Technologies in Yeovil where Paul Jones spoke with Steve Wright from Heidenhain to discuss the company’s diverse range of measurement probes.

Telling MTDCNC about the history behind Heidenhain manufacturing probing systems, Steve told MTDCNC: “We have been manufacturing probes for over 35 years, so it’s definitely one of the best-kept secrets of the machine tool industry.” With two probing systems in action on a YMT machining centre, Steve first explained how the probes work, saying: “Probes are fundamentally a very accurate switch. When the probe triggers on the workpiece or on the tool, it then captures the axis position and that is then sent back to the control unit. This information is then used to align the workpiece position within the machine, measure the workpiece or measure the geometry of the tools.”

Alluding to why manufacturers should use probes, Steve continues: “They will increase productivity and efficiency of the machine tool. They will reduce manual setup time by using a spindle probe to set up a component inside the machine. For the tool probes, you can measure your tools inside the machine rather than use the preset outside of the machine and then manually enter the data on the CNC. Secondly, with the inspection probe in the spindle, you can actually inspect the component inside the machine. This means you do not have to move apart from the machine, take it to the inspection department and then re-loading for any subsequent reworking operations.”

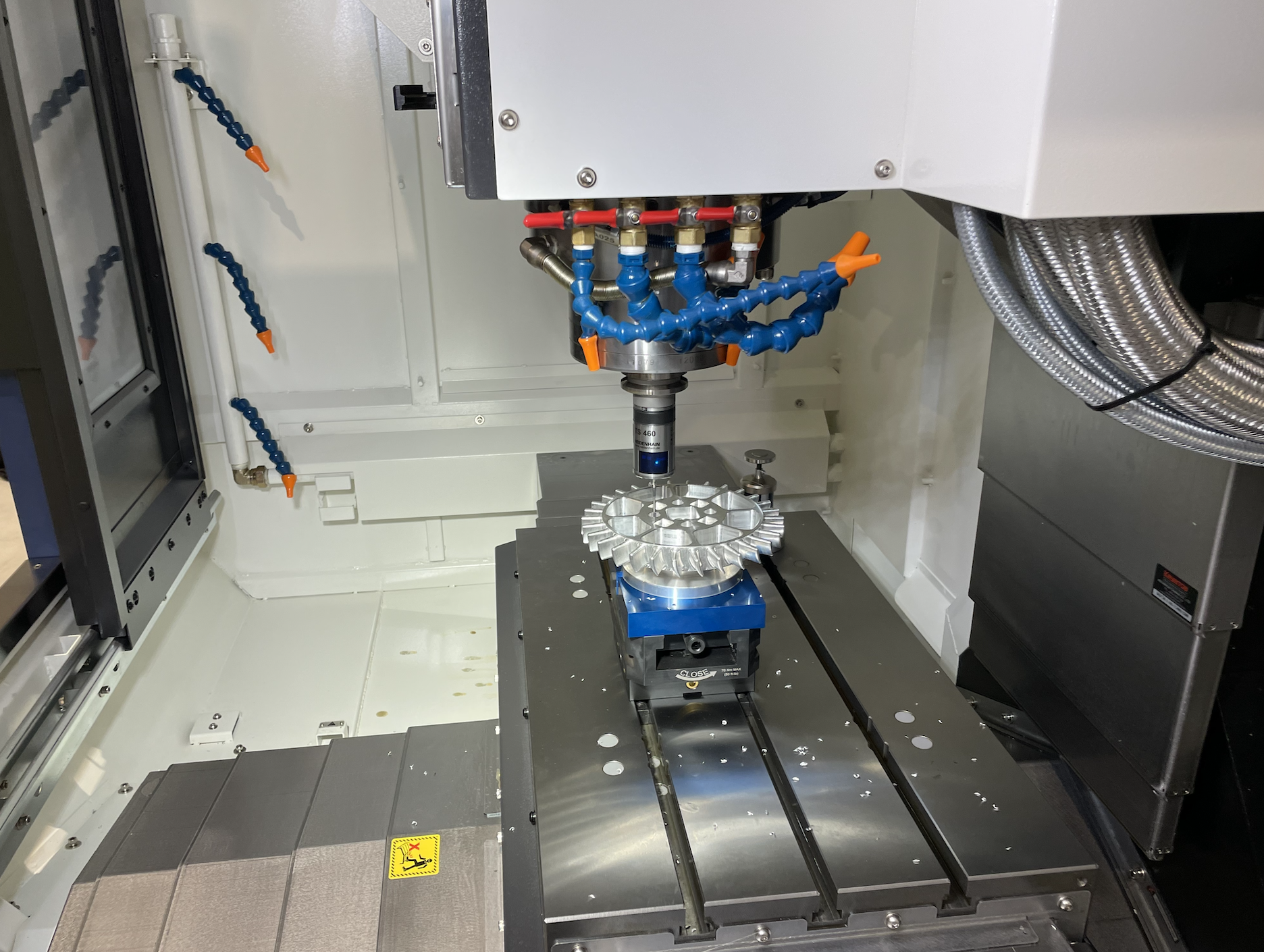

Looking at the specific probing solutions, Steve continues: “Here we have our TT460 two probing system for monitoring measuring and checking cutting tool length and radius. It’s a wireless system that connects remotely to an infrared transmitter in the machine. With regards to set up, it is simply mounted on a base unit on the machine bed and there is a magnetic version. You can use then an inbuilt probing cycle to determine where the probe is and do a calibration cycle. The next unit is the TT160, it has the same functionality as the wireless version in that it has a cable outlet and it is physically hardwired to the machine.”

Moving on to the measurement probes, Steve takes a closer look at the TS460 system. “This is the spindle probe for setting up your components inside the machine and doing an inspection of the parts. This is a wireless version of the probe that can communicate via infrared or radio signal with the receiver.” Discussing features that are specific to the Heidenhain probes, Steve continues: “The first feature is a collision protection ring at the base of the probe. This acts as a second defence to protect the probe body. So, if you had an unexpected contact between the probe body and the fixture or workpiece, the probe would deflect and protect the electronics and mechanical workings of the probe. Furthermore, this deflection device acts as a thermal decoupling device, so any heat generated in the spindle cannot be transferred to the probe. This eliminates any potential for thermal growth and inaccuracy via the probe.”

“The second interesting feature is the three outlets that run through the probe. This allows compressed air or coolant to travel through the probe, this is to clear any swarf from the workpiece before doing any measurement.”

“The second interesting feature is the three outlets that run through the probe. This allows compressed air or coolant to travel through the probe, this is to clear any swarf from the workpiece before doing any measurement.”

Discussing how the systems work with the receiver, Steve says: “We use the SE660 receiver that is capable of transmitting either an infrared or radio transmission. The one receiver works with both the spindle and tool probing systems. Primarily, the radio transmission is more commonly used in larger machines if you have instant is where the fixtures or workpiece will block the line of sight between the receiver and the probing system.”