I would like to thank the MTD Magazine team for inviting me back to write more articles after a break of 18 months. My last article, the last of a 3-part measurement series was written at the end of 2020. In that same year, we all had to miss the planned MACH 2020 show due to Covid. April will see the return of MACH, and I, like the rest of the industry have missed the showpiece event. The theme of this year’s show is skills and development, something close to my heart and a necessity if we are to meet the needs of smart manufacturing and its productivity promise. By Ian Wilcox

My area of expertise is metrology and like many lifelong engineers, I could fill pages about the issues surrounding skills development in my discipline. Skills shortages are not new. It’s been one of the challenges since well back into the last century and has never really been fully resolved. You could make a convincing case that when the third industrial revolution was strongest throughout the 1970s, we started to lose our way. Our manufacturing engineering sector was on the back foot financially and government support for the sector was ebbing away. This double whammy naturally starved and weakened many of those that supplied engineering skills training, particularly private companies and colleges. In every decade since, successive governments have tried to reignite it, but…..well, what do you see?

But now is the time and opportunity to move forward, not look back.

Metrology skills are not the only factor in good industrial measurement, as important as they are. Having good measurement technology, sound application and close cooperation with other disciplines such as production and design are also factors that enter the mix. In addition, we should also look at that often missing ingredient, what is the objective and the plan to achieve good metrology. Each is as equally significant as the other.

It is easy to fall into the trap when a company expands production or, a measurement system needs replacing, to just go out and buy like for like. But before you do, ask yourself, is it just the technology we need to upgrade? At MACH, you will certainly see many examples of innovative and ingenious technology, but do you have the skills to select and optimise the usage of the one technology or the mix of technology that suits your measurement applications best. Is the new measuring system just replacing the old, outdated measurement system with no other changes? Or is the system fitting in with how you currently work, rather than being considered as part of a wider opportunity?

For example, if a company bought a new machine tool or moulding machine, surely you would use all of its improved benefits to optimise productivity. You would look at the whole production line, cell or process and make the adjustments to the whole – you would not install and under-utilise this new system so that you don’t have to change the wider process. Wouldn’t you have a plan and take the wider opportunity that the new technology offers? Is that also the case with your measurement equipment?

In today’s manufacturing companies, it is common to have measurement hubs. Measurement systems, particularly coordinate, software-driven systems are often a large investment. Their capacity is often greater than the needs of any single production line. By having hubs or even one central measurement room, if demand is sporadic or environmental requirements are specific and costly, OEE of equipment and operators can be kept high by centralising the measurement systems and skills.

However, production parts are diverted away from their production added-value activities and join the queue at the hub. The data you need from measurement, is not always quickly returned and so lagging true process control. These hubs are often not a process-driven place, usually having an uncontrolled irregular flow of parts with no production processes other than some basics. No lean thinking here.

As a hub, the measurement technicians and inspectors that staff it, often report to quality. There is no connectivity with any one production line and so, no personal investment in focused productivity. Production constantly questions results when they challenge what they anticipated. Trust between measurement and production breaks down. Sometimes however personal relationships can obscure the reality of that disconnection, good people can make things work.

By having multiple feeders of parts to measure, from several lines and even buildings to service, workflow becomes difficult to manage and ‘investigations’, ‘rechecks’ and fixture changes all disrupt the flow, causing bottlenecks. The irregular return of results causes inflated unproductivity when issues do occur. All adding more heat to the ‘them and us’ disputes. I paint a bleak picture, but it’s one I have seen regularly enough. It is a challenge for some, but not an impossible one.

Use lean, create processes and their subsequent procedures, try to engender productive thinking in the hub and when you need to replace measurement equipment, ask yourself ‘like for like’ or could you solve some of the wider issues of measurement and productivity with alternative use of technology. Try to bring measurement and its underpinning metrology closer to production, both in terms of cooperation and in physical distance. The closer it gets, the more its processes can be integrated with the flow of production.

Companies that are now looking closely at productivity are considering modern technologies both as part of normal regeneration, but it has also been speeded up by the realities exposed by the pandemic. The pandemic randomly took skilled people out of the business for days at a time, not only taking resources when it was needed, but also their knowledge and experience was temporarily removed. It exposed a reliance on an under the radar network of unrecognised skills and ‘make it work’ relationships. The disruption this caused was felt by many, but not always fully appreciated and recognised by all. There is now a new drive to better control and understand processes and skills to catch up with automation.

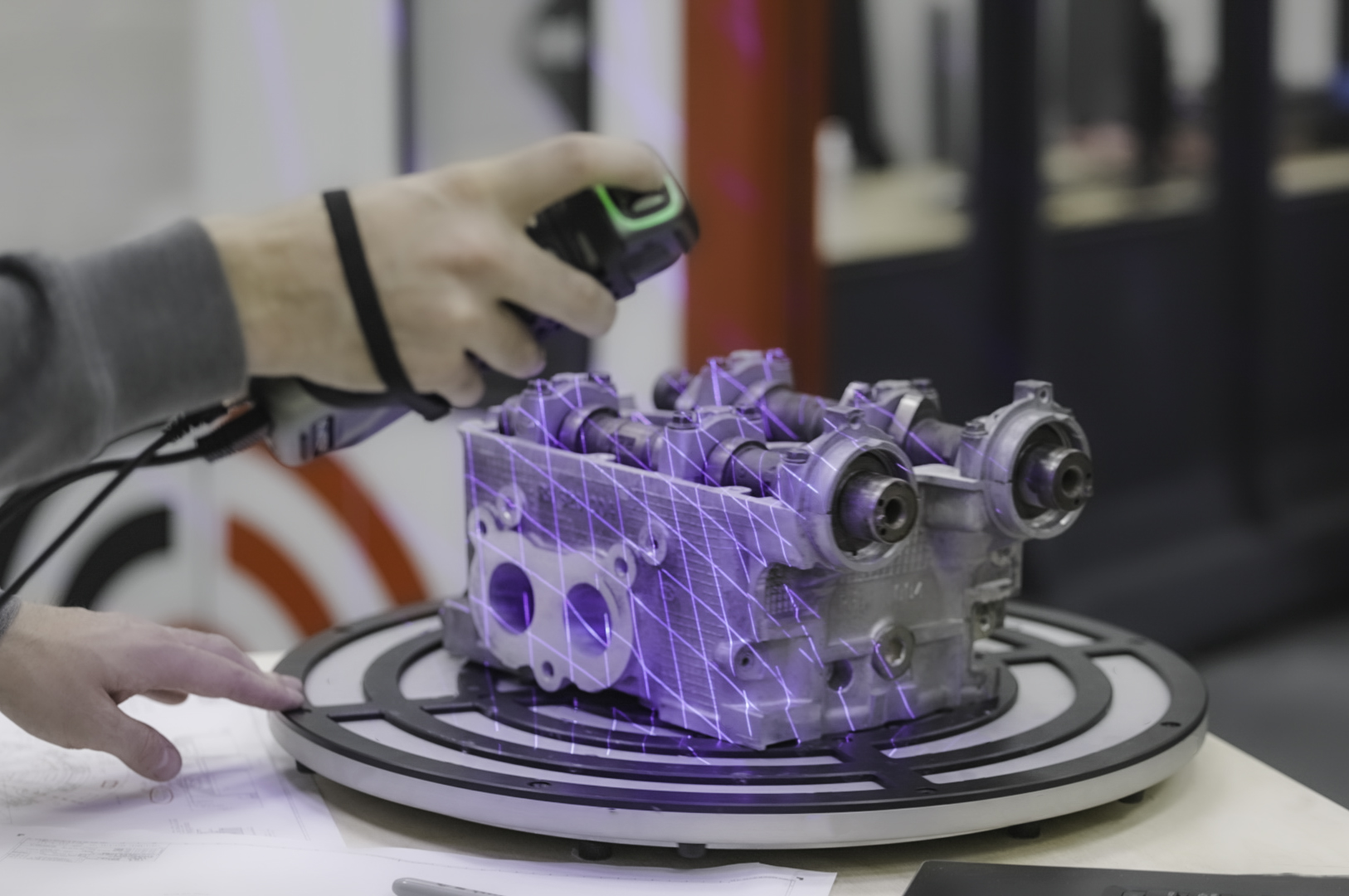

The forward leap in measurement technology means a quite different MACH show to the ones you may remember, especially if you have not visited for a decade or more. As well a wealth of new types of systems based around photogrammetry and laser arrive, there are more alternatives to applying a traditional CMM in certain applications. You will now also see that culmination of ‘Industry 3.0’ as many will be demonstrating robot loading and sensor handling, paving the way for the journey into ‘Industry 4.0’ or smart manufacturing as some prefer. Manufacturers need to challenge their thinking over integrating measurement into production. Engineers need to consider cell or line-based measurement that is included in the Takt time to drive process control and build added value with productivity gains. The opportunities currently in front of UK manufacturing are the pull, the need to catch up quickly is the push.