Precision specialist invests in a new DN Solutions’ DNM 4500 to increase its machining capacity, strengthen its position in customers’ supply chains and improve the productivity and efficiency of its machine shop.

Mills CNC, the distributor of DN Solutions (formerly Doosan) and Zayer machine tools has recently supplied Ad Hoc Engineering Ltd with a new DN Solutions’ vertical machining centre. The DNM 4500 machine was installed at the Warwickshire company’s 1,700sq/ft facility in March and has been positioned near three other Doosan machines acquired over the last nine years. The machines include an 8” chuck Lynx 220 lathe, a DNM 500 II VMC and a 6” chuck Lynx 2100 lathe, installed in 2014, 2015 and 2019 respectively.

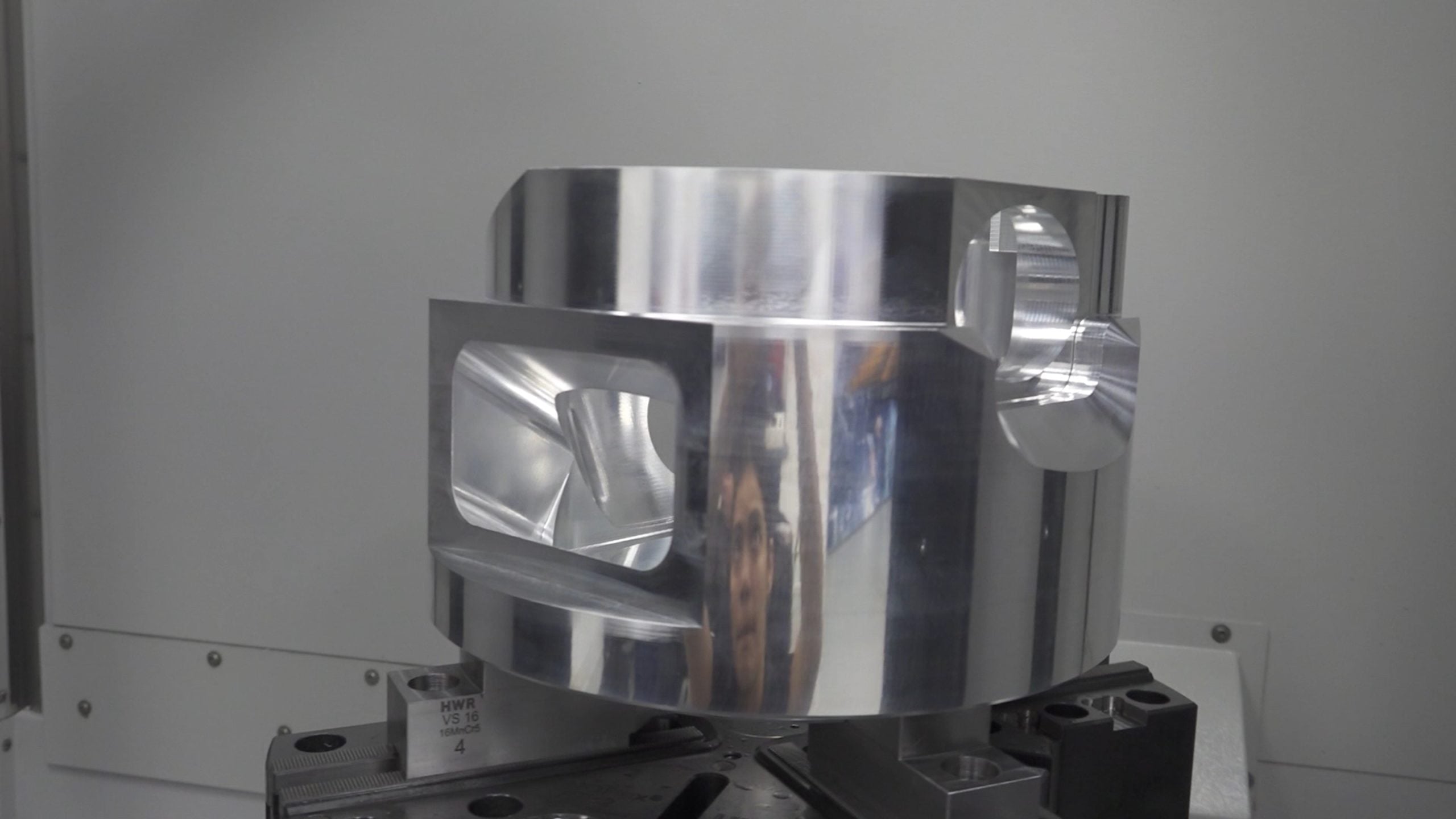

Collectively, these machines along with the recent addition of the DNM 4500, provide the company with a flexible in-house machining resource. The new DNM 4500 is being used to machine a range of precision components and families of parts such as housings, enclosures, valves and actuators for proprietary flow meter and scientific instrumentation products that are designed in-house.

Once machining and inspection have been completed, parts are sent out for surface treatment operations such as plating and powder coating before returning for final assembly, testing and delivery to customers in the electronics and process control sectors. Parts machined on the new DNM 4500 are typically made from aluminium, mild steel and stainless steel bar and billets that are machined in batch sizes from prototypes through the thousands-off using advanced workholding that includes pallets and tombstones. Part tolerances are tight, but the main machining requirements are consistency, repeatability and fast processing speeds.

A new machining centre

With demand growing for its design, machining and assembly services, the company decided in 2022 to improve its milling capacity and capabilities. Two, older machines the company had at its disposal were creating production pinch points that were affecting output. After careful consideration, the decision was made to replace older machines with a new, higher-specification machining centre.

As John Watts, company Owner and Director says: “We provide high-quality machining services to customers and we are a vital cog in their process chains. As such, we need to be able to anticipate and respond quickly to their changing production requirements. To maintain these supply chain relationships, we needed to strengthen our in-house milling capabilities by investing in a reliable, high-performance production-oriented machine that would meet both our and our customers’ immediate and future requirements.”

As a consequence, the company drew up a detailed specification checklist for its new machine tool investment with several ‘must haves’. This included a Fanuc CNC to ensure the quick and easy transfer of programmes between the new machine and its previously acquired DNM 500 II machining centre, a large machining envelope for machining multiple parts in a single set-up, a powerful spindle capable of machining a range of different materials and delivering fast part processing speeds and a reliable, versatile and proven machine with an established track record that was available at a competitive price.

As John Watts continues: “As an existing Doosan user, we have good relationships with Mills CNC. We like their business approach and the three existing Doosan machines have all performed well and haven’t missed a beat. It therefore made sense to contact Mills and, having discussed our needs and requirements with them and seen a DNM 4500 in action at their showroom facility in Leamington, it was a ‘cut and dried’ decision.”

The flexible DNM 4500 3-axis machining centre is equipped with an 18.5kW/ 12,000rpm BT40 direct-drive spindle, a 30-tool position ATC, a 1m by 450mm worktable with a 600kg maximum load and the advanced Fanuc 0iMP control with a 15” touchscreen. The machine was also supplied with through-spindle coolant capability and a Nikken 4th-axis rotary table.

In conclusion, John adds: “We needed a fast, accurate and competitively-priced machining centre. With the DNM 4500 – that’s exactly what we have got.”