Mitutoyo is a world leading brand with a product range that far exceeds that of other metrology manufacturers. The measurement colossus has its UK head office in Andover with additional facilities in Halifax, Coventry and East Kilbride – but not all manufacturers are aware it has a Measurement Services Department. Based out of Halifax and Coventry, the two facilities are dedicated to offering subcontract measurement services.

Mitutoyo’s Measurement Service Department was founded to help manufacturers bridge the gap between customer expectations on quality and delivery, and the limitations of in-house inspection. UK manufacturers have taken full advantage of the subcontract measurement services to exceed the expectations of customers. So MTDCNC took a trip to Halifax to see the facility and its use of the Renishaw 5-axis REVO inspection head, which is helping to achieve turnaround times that are beyond that of other service providers.

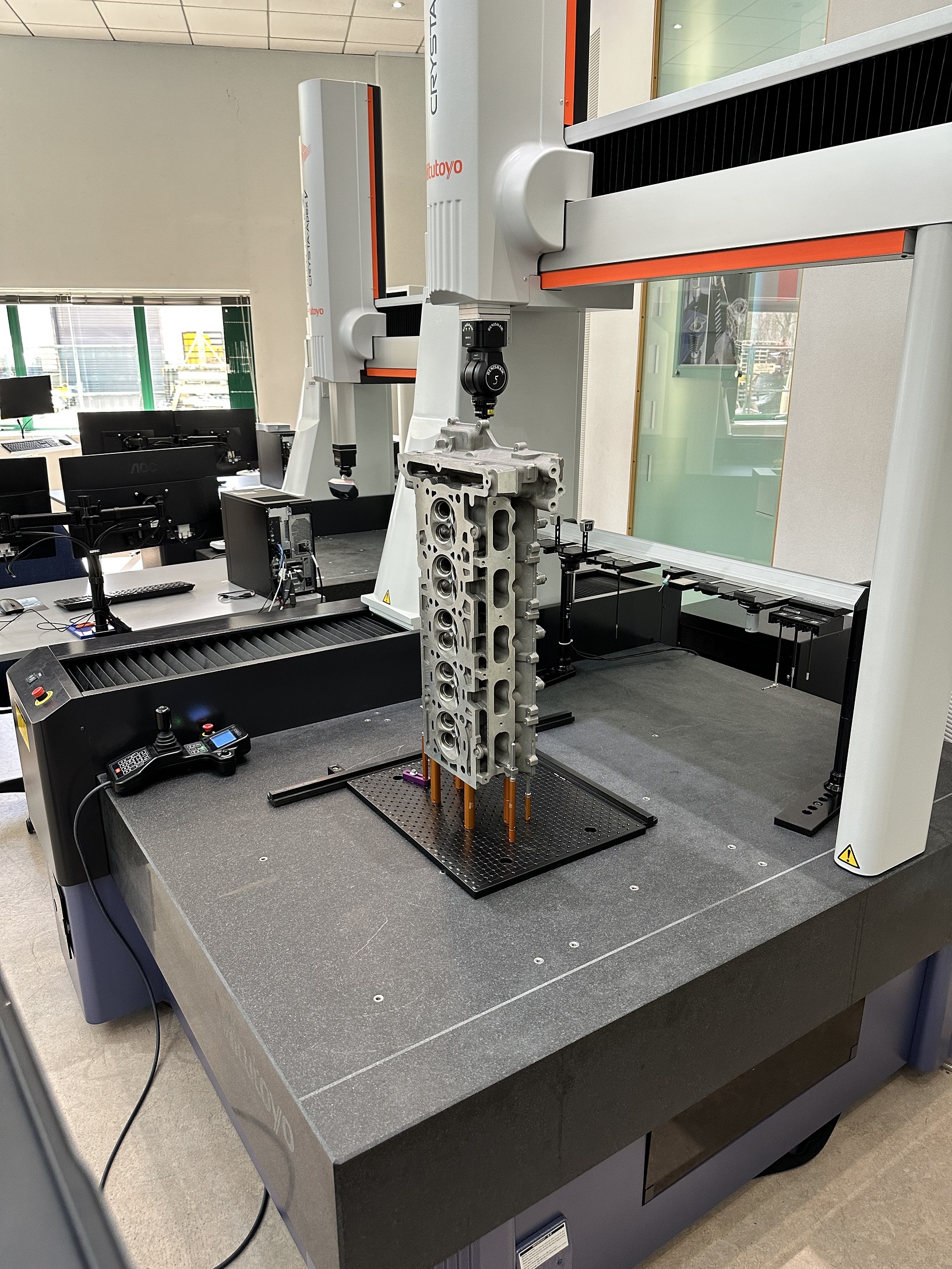

Andy Fifield, the Measurement Services Manager at Mitutoyo UK says: “The Renishaw REVO head is one of the fastest most capable systems and it has a place by our CMMs. In the UK, Mitutoyo CMMs are set apart from others on the market because of their well-established capability and reliability. It is very important in metrology that we can measure parts quickly, but also that we provide a reliable platform, so that customers don’t have any interruptions in the inspection cycle.”

Nowhere is this sentiment more prominent than in the Measurement Services Department where Mitutoyo deploys its solutions to deliver results, as Andy continues: “We also have some of the most capable software that you can get for a CMM. We have our M-COSMOS software which is a very capable platform. It provides benefits to our customers so that they can quickly and efficiently programme parts and deliver accurate measuring solutions. For manufacturers that require a complete subcontract measurement solution, our teams deliver a complete service with the application of our industry-leading CMMs, world-leading software and expertly trained staff.”

“The Mitutoyo products are used by a wide range of industries, right from small subcontract engineering firms through to the largest aerospace firms in the UK which of course need very precise solutions. Mitutoyo has always strived to deliver cost-effective solutions to our customers. So, when we think about what we want to deliver to our customers, we think about trying to deliver cost-effective solutions that are available for everybody – and trusted by the best.”

Discussing the partnership between Renishaw and Mitutoyo, Chris Sargent, CMM Applications Engineer at Renishaw PLC says: “Renishaw has been making probes for 50 years and most machine tools and CMMs are supplied with Renishaw equipment. Mitutoyo has been working with Renishaw in the UK for more than 30 years, and all Mitutoyo CMMs and indexing heads are supplied with Renishaw equipment on them. Mitutoyo is a Renishaw premium partner for REVO.”

Alluding to Renishaw REVO and how it enables companies like Mitutoyo to gain a competitive advantage over its rivals, Chris continues: “REVO is a 5-axis CMM inspection head that runs on air and has an A and B-axis to add two additional axes to a 3-axis CMM. Traditional 3-axis CMMs have an intrinsic dynamic error in the machine framework. The REVO head with its A and B-axis eliminates that dynamic error on inspection of certain bores and certain features that don’t involve a CMM movement.”

“REVO is faster than traditional 3-axis CMMs because it doesn’t have to rely on the movement of the framework of the CMM. Therefore, it can scan bores and other features much quicker, just by moving the head itself. REVO can scan data up to 4000 points per second which is 80% faster than its 3-axis competitors. This provides a 50% decrease in cycle times in a production environment. Manufacturers utilising the Mitutoyo M-COSMOS system can use Renishaw’s scanning probes to scan bores up to 500mm a second. There are also surface finish probes available with a variety of modules to suit different uses and Renishaw’s ultrasonic probe for capturing data on wall thicknesses up to 20mm. Now, all Mitutoyo CMMs with indexing heads are supplied with Renishaw technology, so manufacturers can benefit from the diverse and technologically advanced solutions from both Renishaw and Mitutoyo.”