🎧Hirschvogel revs-up optimisation with Vericut

As an automotive supplier manufacturing up to 20,000 parts per day, the Hirschvogel Group operates at the pinnacle of automated series production where optimised cycle times are essential. By using Vericut simulation and optimisation software, machining processes can be analysed and optimised for series production in advance.

From Village Forge to Global Manufacturing Leader

Founded in 1938 as a village blacksmith in Denklingen, the Hirschvogel Group has grown into a global leader in producing and refining highly formed steel and aluminium components for the automotive sector. With around 6,000 staff across nine plants worldwide, generating €1.21bn in revenue and producing 342,000 tonnes of steel and aluminium annually, the company supplies well-known car manufacturers with technically advanced, ready-to-install components.

Today, Hirschvogel ranks among the world’s largest automotive suppliers in hot and cold forging of steel and aluminium, plus subsequent machining. Its customers include all major automotive manufacturers and suppliers worldwide, with the company producing components and assemblies for drivetrains, transmissions, chassis, bodywork, fuel systems, combustion engines and electric motors.

Development Partner and Manufacturing Specialist

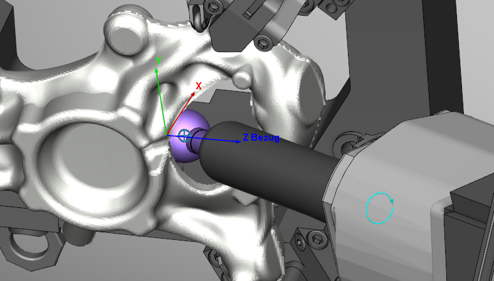

A clear trend shapes modern automotive manufacturing: “The components we develop are constantly becoming lighter whilst also needing to withstand high loads,” explains Peter Zotz, responsible for machining process development at Hirschvogel’s Schongau plant. Hirschvogel brings extensive experience and innovation to highly stressed, weight-optimised parts and components.

From forged parts to ready-to-install components, the family-owned Bavarian company provides everything from a single source. “We are a development partner and manufacturing specialist for the automotive industry. Besides forging, machining plays a major role in production,” says Zotz. As a cost-sensitive supplier dealing with high volumes, every penny and second counts. “That’s why we’ve been using Vericut since 2013. It allows us to identify errors and optimise our manufacturing processes before actual machining even begins.”

Zotz emphasises the critical importance of advanced optimisation: “Thanks to the process reliability gained through Vericut, we are able to optimise the machining of formed steel and aluminium components.”

Vericut as a Key Component of the Process

At Hirschvogel, all machining programmes are written manually as NC code using an editor. “This is the fastest process for our needs,” says Philipp Berchtold, responsible for programming at the Schongau site, explaining this unconventional approach. As components become lighter, more complex and must be delivered ready for installation, machining challenges increase. To verify and optimise these programmes, Hirschvogel relies on Vericut.

Because each part is optimised as much as possible, Hirschvogel uses a wide range of control types and machine tools. “Vericut is completely independent of control systems, and we can test and optimise our parameterised programmes at our desks before a single chip is cut,” Berchtold explains. For him, “The simulation and optimisation software Vericut is a firmly established and indispensable part of our process workflow.”

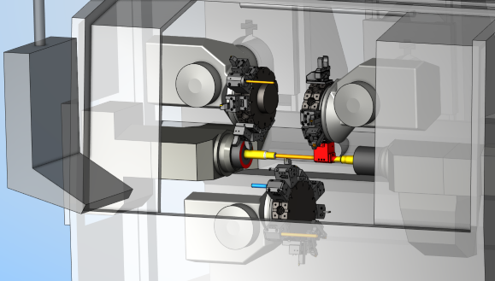

“For the user, it’s the safest way to simulate real machining using a virtual machine,” adds Dirk Weiß, responsible for sales in Germany and Austria at Vericut. Hirschvogel’s product development process divides into distinct phases. In the quotation phase, space analysis of the production system takes focus. “Here, critical tools, clamping devices, loading/unloading and turret swing-outs are checked,” explains Berchtold.

Once the system concept is finalised, the process development phase begins. “Each machine or control uses its own defined programme structures consisting of up to 150 subprogrammes,” says Berchtold, illustrating the complexity. Depending on the situation, existing programme structures may be reused or must be newly created or adapted.

In the third phase, the component’s suitability for series production is reviewed by the responsible department and in-house automation technicians. After final approval, Vericut performs collision checks and process optimisation. “We focus on smooth production flow with no downtime to avoid any delays during actual machining,” Berchtold explains, adding: “And all of this happens before the part even reaches the machine.” The simulation takes only a few minutes. “If an error is found, you can fix it and continue simulating from that point,” adds Weiß.

Comprehensive Data Package for Production

The programming department at Hirschvogel creates a comprehensive data package for each part for series production use. It includes the programme structure, the programmes themselves, a reviewer file for feedback from production colleagues, and a machine setup sheet. “This data package speeds up setup and programme adjustments, which leads to significant cost savings,” says Berchtold, pleased with the results.

This systematic approach ensures seamless transition from development to production, minimising potential errors and maximising efficiency throughout the manufacturing process.

Further Optimisation with Advanced Capabilities

Thanks to the process reliability provided by Vericut, Hirschvogel optimises machining of forged steel and aluminium parts for the automotive industry before production begins. “We are currently testing additional feed rate optimisations using the Vericut Force module, which we expect will yield another productivity boost,” says Berchtold. Force is a physics-based optimisation method that determines the maximum safe feed rate for given cutting conditions based on cutting force, spindle power and maximum chip thickness.

Weiß reinforces the importance of this capability: “In series production, every second counts—manufacturing processes must be optimised and machining operations pushed to their limits. With Vericut and the Vericut module Force™, we offer highly cost-effective support in this area.”

Together with Vericut, Hirschvogel is also working on achieving even more detailed cycle time analyses. “We aim to reduce theoretical cycle time deviation to under one per cent,” concludes Weiß, highlighting the precision and reliability that makes Vericut an indispensable tool for modern automotive manufacturing.