For 50 years, the Dutch manufacturer of gantry milling machines and machining centres, Unisign, has been implementing machine concepts that are engineered to meet specific machining requirements. A vertical integration of over 80% ensures that the company retains its expertise. All workpieces requiring high precision are manufactured in-house. For grinding, the company relies on the Swiss grinding machine specialist KELLENBERGER, available in the UK from DF Precision Machinery.

What drove Bart van Ruth to found his design office exactly 50 years ago was the desire to find technological solutions for productivity improvements. The development of his first proprietary product, a vertical, column-mounted CNC drilling machine with a fixed machine bed, brought success, primarily in the German market. In 1988, the first gantry milling machine for 5-sided machining of workpieces was presented.

Today, Unisign gantry milling machines, travelling column machines, and multitask machining centres are supplied to logistics and energy companies, commercial vehicle manufacturers, and general mechanical engineering companies around the world, many of them as special-purpose machines. The range of parts includes lorry front and rear axles, chassis side members, lifting mast profiles, excavator frames, crane beams, and railway bogie frames, which are often manufactured on Unisign machines in a single setup. The machining length of the machines often exceeds 25m—understandably so, given the size of these workpieces. Unisign machining centres are used to machine, amongst other things, pumps and valves for the oil and gas industry and sophisticated components for energy systems.

Innovative technologies have always played an important role at Unisign. This tradition is continued by Paul van Ruth, who has led the company since 2008, representing the second generation of the family. At the Unisign Technology Centre, a dedicated research and development department continuously develops new machine concepts that offer solutions for specific machining problems.

“Here, we can impressively demonstrate what our machines can do,” says Operations Manager Paul Lennaerts, who is responsible for design, production, purchasing, and assembly. The mechanical engineer has been with the company since 1991 and initially spent a long time in customer service. “We show customers how our machines can increase productivity in a production facility,” Lennaerts explains, adding: “In our own production, we naturally machine the components for our machines primarily on Unisign machines, at least when it comes to turning, milling, and drilling. For other machining operations, we rely on machines from manufacturers whose quality commitment matches ours, as we experience with Kellenberger, for example.”

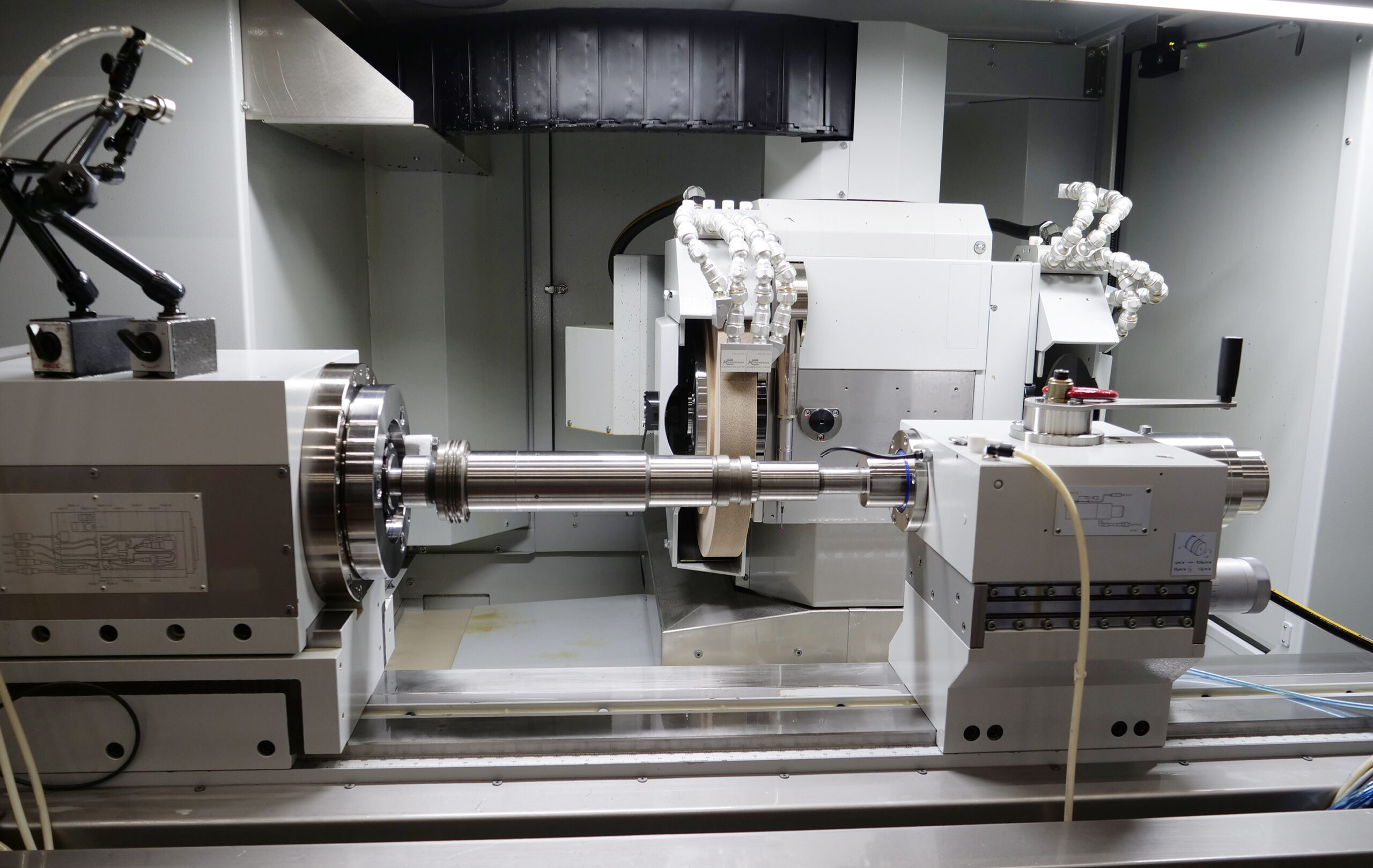

For grinding high-precision parts such as drawbars, mandrels, and spacer rings, a KELLENBERGER KEL-VARIA (the predecessor of the premium KELLENBERGER K1000 series) with Heidenhain control was purchased in 2003. The performance spectrum of these machines is geared to the high demands of precision manufacturing of prototypes as well as small and medium-sized series. A solid machine table with a reinforced machine bed provides very high static and dynamic rigidity and stability, both crucial factors for the highest machining and surface quality, high precision, and high productivity.

In 2021, a KELLENBERGER K1000, was purchased for capacity and for performance requirements. René van der Peet from the sales company BMT Machine Tools BV, which has represented the KELLENBERGER, HARDINGE, and BRIDGEPORT brands belonging to the US Hardinge Group in the Netherlands for years, acted as a consultant. He expertly supported the selection process for the new machine. “When purchasing a machine, we carefully consider all parameters and leave nothing to chance,” says Paul Lennaerts. “Our workpieces vary greatly in size and machining type, and we primarily machine small batches and individual parts. This means the machine must be very flexible and ensure high production and process reliability.”

The KELLENBERGER K1000 is equipped with hydrostatic guides on all main axes for maximum dimensional accuracy in grinding tasks with interpolating axes. The CNC-controlled B-axis for the grinding head is mounted on hydrostatic bearings, thus ensuring wear-free operation. It features a direct drive with a water-cooled high-torque motor and an angle encoder with 0.1” resolution. This allows the turret grinding head to swivel approximately three times faster and position with an accuracy of less than one arc second. This reduces non-productive time and thus increases productivity, especially when machining requires the swivelling in of different grinding wheels.

From the optionally available centre widths of 1,000/1,600mm and centre heights of 200/250 and 300mm for the KELLENBERGER K1000, they opted for a machine with a 1,600mm centre width and a 250mm centre height. “Our old Kellenberger also has these dimensions. We make full use of the workspace when grinding long mandrels,” says Paul Lennaerts. Of the more than 30 different grinding head variants with external and internal grinding spindles available as standard for the KELLENBERGER K1000, covering every machining requirement, Unisign selected the UR 1-6-7 grinding head configuration with one external grinding spindle and two high-frequency internal grinding spindles with maximum speeds of 42,000 rpm and 60,000 rpm, respectively.

The purchase of the K1000 was well prepared with various grinding tests at the KELLENBERGER factory in St. Gallen. Amongst the parts accepted were Capto C8 holders. These holders are amongst the parts that Unisign manufactures in-house. Following the grinding tests, KELLENBERGER supplied the necessary grinding know-how for the Capto holders with the machine. “That helped us a lot at the beginning,” says Paul Lennaerts. “AVN, our abrasives partner, also contributed greatly to the project.”

The K1000 is equipped with a Heidenhain GRINDplus 640 control system and the KELLENBERGER RED Solution software, which includes a GRAPHIC Guide for programme creation based on 2D component drawings, including DXF import, as well as support through a form and technology editor and the ICON Guide programme flow visualisation for free programme design based on ISO standards. The Heidenhain non-circular grinding module was also selected.

“We are very satisfied with the new machine,” summarises Paul Lennaerts. “It has given us the performance increase we required. And also with Kellenberger Machine Service, we also opted for the remote diagnostics module with integrated IT security, which can be used to resolve minor malfunctions. Overall, KELLENBERGER is not just a machine supplier for us, but also a good consultant for manufacturing processes in the grinding sector.”

A Unisign UNIPORT 6000-P portal milling centre for machining large components for KELLENBERGER machines recently began operations in the large, modern production hall.