🎧 – Flying high at 50

On the 4th of April, Renishaw celebrated its 50th anniversary. As part of the celebrations, MTD magazine featured the company’s Miskin facility in our March issue where we discussed the new £50m investment, net-zero, the manufacturing strategy and how internal methodologies are a driving force for external product launches. We were delighted to be invited back to Wales a second time to meet company figureheads and co-founder Sir David McMurtry to find out more about the origins, the culture that drives the company and its future direction. By Rhys Williams

Renishaw plc is a name that has been synonymous with measurement for as long as most engineers can remember – a true beacon of UK manufacturing ingenuity. The press trip to the Miskin facility near Cardiff in March gave journalists an opportunity to fire questions at senior management and members of the executive board. The most prominent attendees were Louise Callanan, Director of Additive Manufacturing; Paul Maxted, Director of Industrial Metrology Applications; Gareth Hankins, Head of Group Manufacturing; Will Lee CEO and Sir David McMurtry, the Executive Chairman, Co-Founder and all-round fascinating character.

The press conference discussed a range of subjects, but one thing evident was the culture of innovation that has been the backbone of the company for 50 years. Listening to Sir David in the press conference and also discussing a wider range of subjects over lunch; it was fascinating to learn how this humble inventor, engineer and titan of industry weaved a path to half a century of stratospheric success and built a culture of innovation. But before we get to that, it may be worth looking at the company’s 50-year journey, and where it all began. Sometimes, the road already travelled tells an insightful story that isn’t always well known.

Where it all started

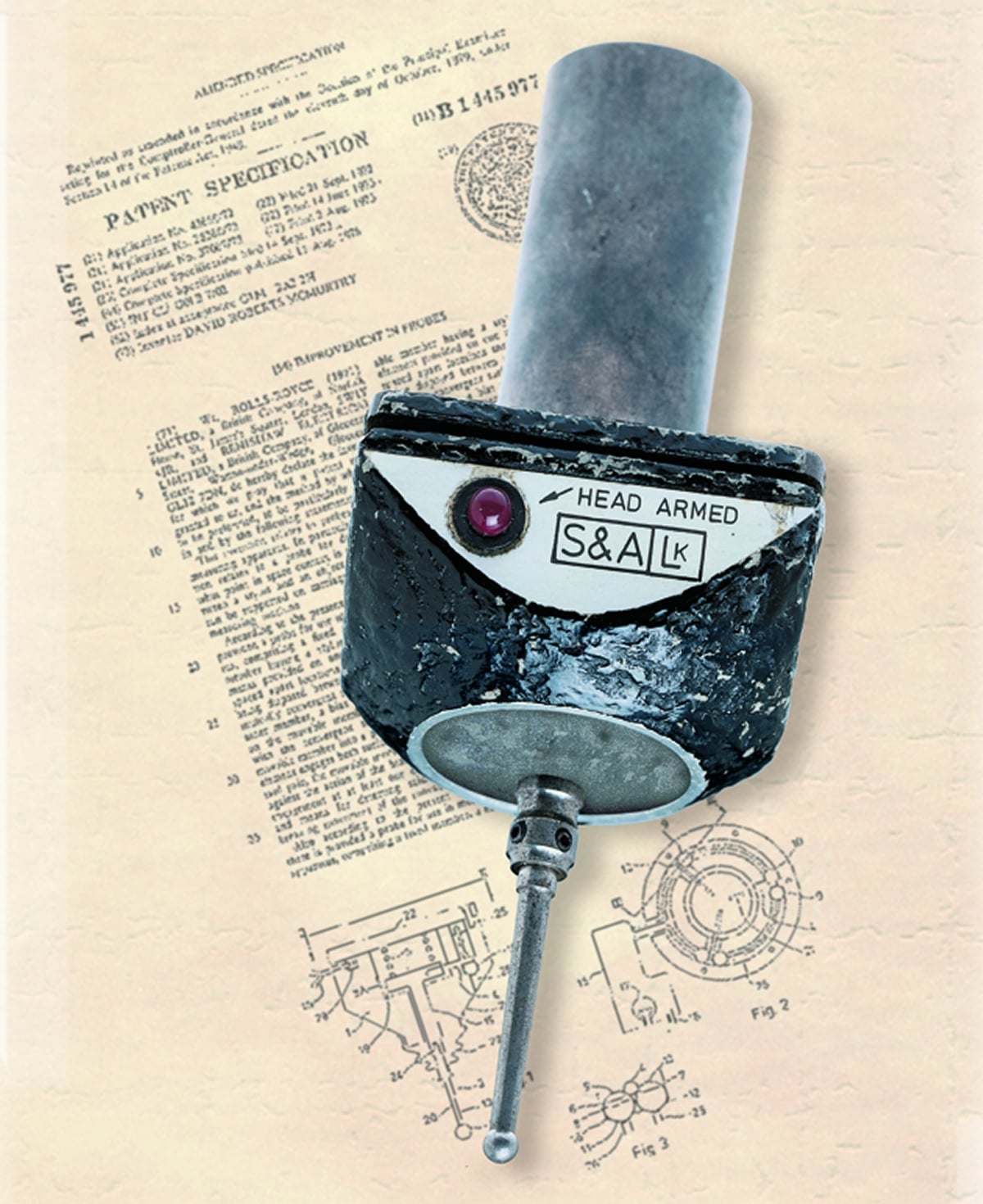

In 1972, David McMurtry was an Assistant Chief of Engine Design for Rolls-Royce, working on engines manufactured at Filton. There was a challenge with measuring the pipework on the Rolls-Royce Snecma Olympus 593 engine that was destined for installation on Concorde, which later took its first commercial passengers in 1976. Working over a weekend to solve the urgent issue, David McMurtry designed and built a prototype touch-trigger probe for CMMs. The probe solved the issues faced by Rolls-Royce – and as we know now, the ability to automate measurement on CMMs later went on to solve measurement challenges faced by hundreds of thousands of companies worldwide.

Rolls-Royce filed a patent on McMurtry’s design on 21st September 1972. Simultaneously, David was discussing the probe with colleague John Deer, now Non-Executive Deputy Chairman at Renishaw; John had a background in machining and wanted to start his own business. As Sir David McMurtry said in the press conference: “I remember working on the probe and continually encountering challenges that needed to be overcome. Back in those days, there were no mobile phones or emails. The factory had the big old phone boxes and I had to walk across the site to make calls to discuss the solution.”

When both engineers identified the wider commercial opportunities for the invention, Rolls-Royce agreed to license the patent, but only if the pair had a limited liability company. To speed up the process, they purchased an ‘off-the-shelf’ company called Renishaw Electric Ltd on 4th April 1973 – and the company we know now as Renishaw plc was born. McMurtry continued to design the early products in Wotton-under-Edge, Gloucestershire and when the company received its first order for 10 probes from LK Metrology for a grand total of £3,333, the company’s manufacturing and admin moved to Deer’s home in Chepstow, South Wales where there was a garage machine shop, spare bedroom assembly area and dining table admin department. In 1976, the small start-up acquired its first premises, a former ice cream factory in Wotton-under-Edge, and with just nine employees, the company was quickly supplying the world’s leading manufacturers of CMMs. With CMM manufacturers located worldwide, Renishaw was built upon the foundations of supplying a global marketplace, something that rings true today with 95% of annual sales derived from exports.

McMurtry and Deer saw the potential for probes to be applied to CNC machines and quickly developed and subsequently demonstrated its first commercial probe at the EMO 1977 exhibition on a Kearney & Trecker milling machine. When the show returned in 1981, 32 machine tool builders had Renishaw probes fitted to machines on their stands – as we know, the rest is a fantastic journey of British innovation that has taken the world by storm.

Now, Renishaw plc is listed on the London Stock Exchange’s FTSE250 index with a current valuation of around £3bn and over 5,200 staff in 36 countries, and while a large proportion of business is still derived from contact and non-contact measurement – it supplies a wide range of metrology systems, process control solutions and it develops systems for non-destructive testing using Raman spectroscopy, robots and drug delivery systems for neuro-surgery as well as being a major player in the additive manufacturing sector.

Products nurtured from an ‘innovation culture’

At present, Renishaw is developing a host of new innovations including its FORTiS enclosed encoders and Renishaw Central which is set to hit the market in 2023. The company notified journalists that it is also making huge leaps forward with additive manufacturing behind the scenes. The major launch for this year is certainly Renishaw Central, a new ‘Smart Factory’ manufacturing connectivity and data platform with an open architecture that collects and presents manufacturing process data, allowing users to monitor and update machining and quality control systems. Its features also allow for manufacturing process parameters to be updated using its unique and patented Intelligent Process Control (IPC) software functionality – Renishaw said the system is expected to receive its world premiere at EMO in Hanover later this year.

Whilst the company kept its cards close to its chest regarding the next step in its additive manufacturing journey, MTD magazine did gather some insights. Louise Callanan, the Renishaw Director of Additive Manufacturing said: “The focus and dream for everyone in additive manufacturing is volume production. It is where the technology needs to go, so as well as the platform products we are continually evolving, and trying to improve the productivity of those; we are also working on the next-generation system. We have a funded project with ATI (Aerospace Technology Institute) and other industry partners that we are working with to address some of those barriers to the adoption of additive, making it more accessible to more applications. We are looking at making it more productive, improving the cost per part and more. We cannot say too much at present, but it will be different.”

Adding to this, Renishaw CEO Will Lee said: “When we talk about additive and it being more widespread, we are looking at the higher volume parts we manufacture internally. If we are doing things where we don’t need unique additively manufactured features – it is then about evaluating the most cost-effective and lowest carbon intensity production methods.”

Of course, with additive set for a paradigm shift in coming years, you could expect one man to be strenuously working on it behind the scenes. As Sir David adds: “Additive is my pet passion at the moment, and it’s been a great experience. Louise has got the job of changing our additive capabilities and I look forward to seeing how that will grow. It’s a golden opportunity when people realise the potential for it, and they learn to design for it. Unfortunately, the CAD systems are designed for the subtractive, not additive process, and aids for additive are just not there yet. So, everybody reverts back to subtractive methods instead of thinking differently and producing parts in a much better way.”

Looking at the additive manufacturing market, Sir David adds: “In the next 10 years, you will see a major change to this sector. When you look at the curve, it is currently very, very slow, but the sector is progressing with generative design and you can already see the ability to create parts that were not previously possible. There will be greater capability and increased volume capacity in the future.”

Innovation in the DNA for 50 years

With ground breaking products in the pipeline, some that are a world away from measurement probes – it’s as ‘clear as day’ that Renishaw is breaking the barriers of convention as much today, as it was 50 years ago. As a technical journalist, I continually hear all the superlatives about how companies are streets ahead of the competition; I’ve heard it all. However, Renishaw is probably the furthest removed from convention that I can recall – genuinely taking manufacturing ingenuity to the industry. Renishaw Central and 3D printing technology are just two examples of how the company has massively pivoted from its origins.

At the spearhead of this is Sir David. MTD magazine asked the inventor and business founder about his 50-year journey, he told MTD magazine: “It’s nice to have seen the business grow and that the momentum is still there, and we can create opportunities for people’s futures.” It was humbling that he glossed over the worldwide success story that he has built. The company has over 1,800 patents and Sir David is named on 240 of these, plus around 50 whilst at Rolls-Royce, making him arguably the UK’s most active inventor, leaving innovators like Sir James Dyson (circa 120 patents) trailing far behind.

Adding to the highlights down the years, CEO Will Lee says: “Looking at the business over 50 years, singling out a product or innovation over that time is extremely difficult, but the single most important thing is the culture which has been instilled. This started with Sir David and his absolute belief in continuous innovation and pushing the boundaries of what is possible. From discussions in my earlier career in product design roles, even when we were developing a product and deciding how to bring it to market, we were still asking ourselves ‘what comes next?’ This approach is instilled in everyone and that is why you see these flows of new innovations coming through from different areas of disconnected parts of the business – because that culture is always there.”

“Another thing that Sir David and John Deer have instilled across the business is their long-term thinking that comes so naturally. One example of that at the moment is the relocation of some of the manufacturing of consumer electronics from China. You only need 10% of the production to move to new locations such as India and Vietnam, for it to be a big opportunity. The discussions at Board level are about how we take full advantage of these changes, how we take all the learning from supporting manufacturing in China to invest wisely in India and Vietnam. That investment is not going to pay back for a few years yet. But we can see it is the right thing to do for our business, investing in our people, skills and infrastructure in these growing markets. This approach to innovation and long-term thinking is instilled in all of us, so why wouldn’t we do it?”

Supporting this, Renishaw’s Head of Group Manufacturing, Gareth Hankins said: “What Sir David and John have instilled in all of us, is that we naturally don’t accept convention. You don’t realise it until you hear our CEO Will saying that, but innovation is subliminally drummed into us – and it doesn’t matter what the topic is. Whether it’s about manufacturing or anything else, it’s always about thinking differently, if everybody else thinks a particular way, why should we think the same way.”

Looking to the future

Following a turbulent period for manufacturing that has seen both Brexit and Covid impact the industry, CEO Will Lee said: “We’ve had a rollercoaster ride where there have been things we have learnt and developed and we are in a much better position coming out of those challenges than we were before. We may be a long-term business, but not even we can look at the next 50 years. But concerning the next 5 to 10 years, we now have some very interesting business areas coming through in which we are investing. We believe we can really compound on the growth that we are currently seeing.”

Echoing this statement, Sir David says: “During the downturns, we invest in R&D. This is where we see an opportunity to accelerate our business in different areas and grow in different directions.”

The final word

Meeting Sir David McMurtry was a huge honour for all of the journalists that attended the event; to meet a man so instrumental in the evolution of a manufacturing institution like Renishaw. At the age of 83, Sir David still works in the business – almost daily. His passion for manufacturing and his ability to innovate is as prominent today as it was 50 years ago. Edging towards his 80’s, Sir David founded McMurtry Automotive in 2016 and developed the McMurtry Spéirling hypercar – currently, the world’s fastest accelerating production vehicle with a 0 to 60mph time of 1.4 seconds. The car shattered the course record at the Goodwood Festival of Speed in 2022, and when an F1 car accelerates to 60mph more than a second slower than the McMurtry Spéirling – you know the inventor can break the rules of convention in whatever he turns his hand to.

Over lunch Sir David expressed his regret at the lack of support for UK manufacturing. Without divulging the details, it would appear that once again, despite our manufacturing heroes continually lobbying the UK government to give our industry a fair deal and help us to grow a stronger manufacturing base, regardless of the political persuasion – the government is tone deaf to the cries of our sector. However, innovators like Sir David will always find a way to succeed – after 50 years of developing one of the UK’s most successful manufacturing businesses, countless new product lines and thousands of patents and creating a culture and legacy of innovation – Renishaw looks destined to continue achieving great things in the future.