As part of its ongoing investment drive, subcontract manufacturer Future Design & Engineering has implemented the FactoryWiz machine and equipment monitoring system from RAM Engineering & Tooling Ltd. MTDCNC visited the Bedfordshire subcontractor to understand what benefits this exciting data collection and analysis system can deliver for your machine shop.

FactoryWiz is a system that collects activity status on assets such as machine tools, robots and assembly lines and presents data in real-time. This enables businesses to take immediate corrective action and make future informed decisions based on historical facts. The system can compare collected information based on shift, job number, part number, parts produced, individual machine or machine groups and departments. All reports are open and customisable using Crystal Reports, Power BI, or they can be exported to Excel. The reports can also break down common idle reasons, alarms and alarm messages as well as tool and workpiece offsets showing old and new values along with the timestamp of the change.

Commenting upon what FactoryWiz has done for Future Design & Engineering, Simon Humphrey says: “It has certainly highlighted areas of inefficiency in our machine shop. Whether its vertical machining centres or our multi-pallet machines, before we had FactoryWiz it was just a guessing game. We analysed data manually, we used manual timesheets – and we just had data that wasn’t really useful for our business.”

“With this new system we can bring our efficiency up and we can also look at new investments in machinery that will be more efficient for our business. What FactoryWiz gives us is information like the cycle times, downtime, batch quantities, scrap and idle time of the machines. We are trying to move away from the ‘one job one machine’ approach and we are trying to do multi-pallet work, even on our single pallet machines. This will improve our efficiency over time.”

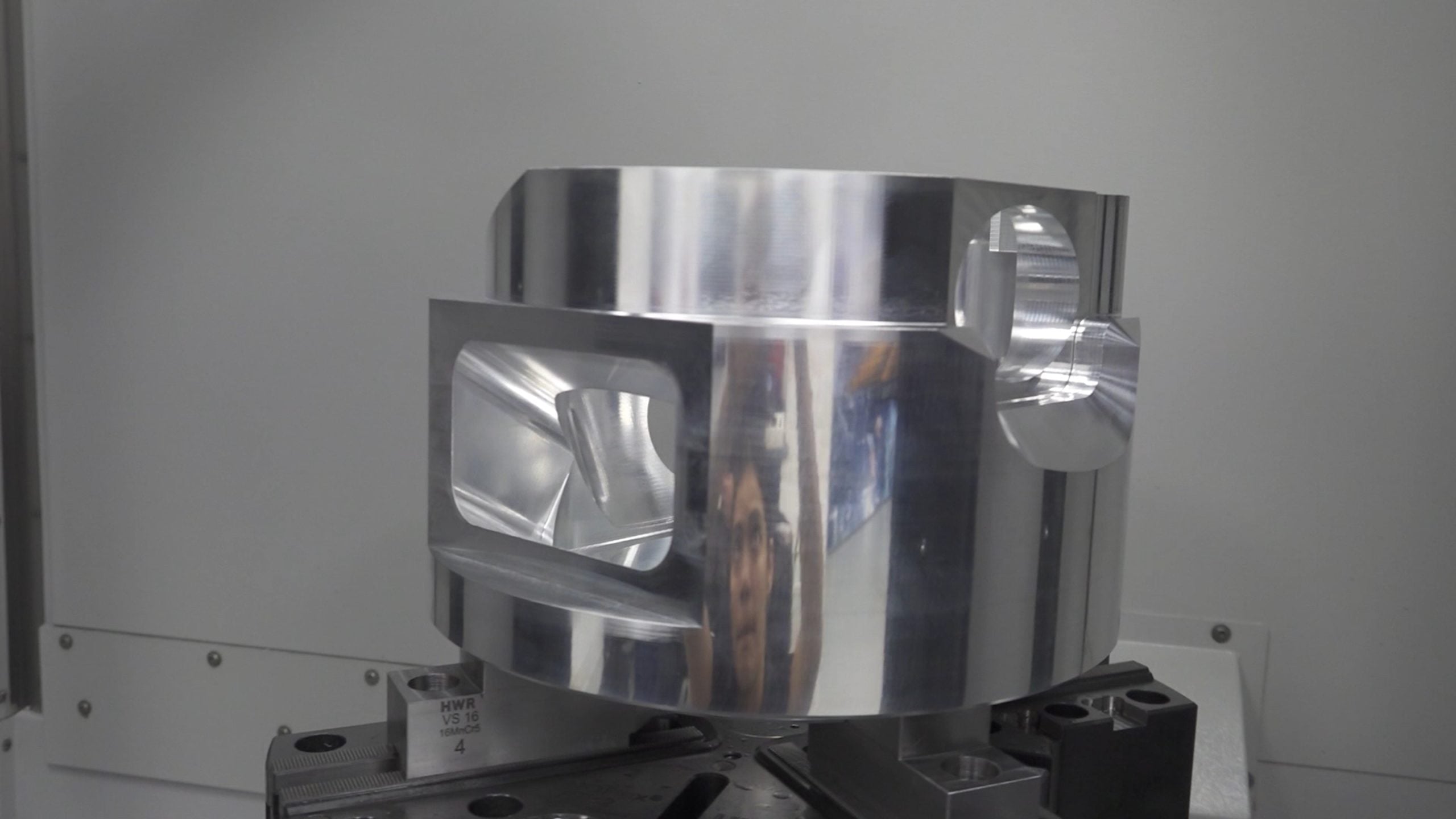

The FactoryWiz system has also identified areas of inefficiency throughout the company that are related to workholding. As Simon continues: “Up till recently we had been using some old-fashioned vices and now we have moved to 5-axis vices, even on our 3-axis machines. This is because they are quick-change systems, and the efficiency is starting to go up.” This is a result of the FactoryWiz system.

The FactoryWiz has been particularly easy to install and apply and it can generate reports on-demand as well as e-mail them automatically at user-defined intervals using predefined settings and filters. Simon continues: “The data from each machine is stored on an internal server that every machine is connected to. We have two sites, so we have got the data coming from the other site as well. The data is instantly live and there is no lag with that. I would certainly recommend it to any machine shop. It has shown us our weaknesses and the inefficiencies in our machines; and we have already increased our efficiencies, which has brought our lead times down. It is making us stronger as a company, so we think it is a great system.”