🎧Drill sharpener pays for itself in five months

Archway Engineering has invested in a drill sharpener from 1st Machine Tool Accessories, and the savings have been incredible. Danielle Toner, Production Manager at Archway, a site drilling equipment manufacturer, is overjoyed with the benefits the company has enjoyed from the new Darex XT-3000.

A US-made Darex XT-3000 for repeatedly regrinding carbide and HSS drill bits to ‘as-new’ condition was delivered by sole UK sales agent 1st MTA to Archway Engineering’s Elland factory in July 2023. By November 2023, it had already paid for itself, as Mrs Toner had not purchased a single new carbide drill in all that time to replace broken or damaged bits. According to the work going through the factory, the saving was between £700 and £1,500 per month.

Mrs Toner said: “We did not previously send drills out for resharpening, so worn bits were discarded. The cost was significant, especially for solid carbide drills. One component we regularly machine involves using a 160mm long, single-flute carbide drill, and we previously needed four of them to complete the part. If we ran out of bits, we couldn’t finish the job until the next drill delivery, which delayed assembly of our products.”

“Now we simply resharpen a bit four times, and we are certain that the component will be finished on time. New carbide drills cost around £165 each, so the saving is considerable and contributes to lowering the cost of production.”

This example is by no means exceptional. Another job requires three new carbide drills to make two parts. In a different process, an HSS taper-shank twist drill is put through 30mm thick EN19 high-tensile steel. A TC shoe made from an S355 hot-finish stainless steel tube is drilled in up to 16 places using a split-point, single-flute carbide drill that has to be repeatedly resharpened before the component comes off completely machined.

Mrs Toner explained that some bits could be resharpened a dozen times or more, depending on their length, while maintaining top quality. It takes about one minute to sharpen the point, or a little longer if necessary to grind past a chip on a cutting edge. It happens quite often due to the toughness of the materials being machined and also because of a frequent need to drill cross holes at various angles into the wall of tubular components. This tends to damage the cutting edges of a drill as it breaks through.

HSS jobber drills from the assembly department are also regularly sharpened, which Mrs Toner describes as ‘a massive saving’. It requires the 220-grit diamond wheel used for sharpening carbide drills to be exchanged for a 180-grit CBN grinding wheel. The process takes about five minutes, so batches of around 20 HSS bits are set aside and resharpened simultaneously.

1st MTA demonstrated the XT-3000 in the Elland factory before Archway Engineering purchased it with an attachment to process bits up to 30mm in diameter. Left and right-hand drills can be processed, and attachments are available for sharpening step drills, countersink and spot drills, and others with a 90-degree point. Standard sizes of carbide drills used regularly by the site drilling manufacturer are 8, 10, 12 and 14mm in diameter and up to 6XD in length. However, bits from 3 to 21mm in diameter can be accommodated in normal use.

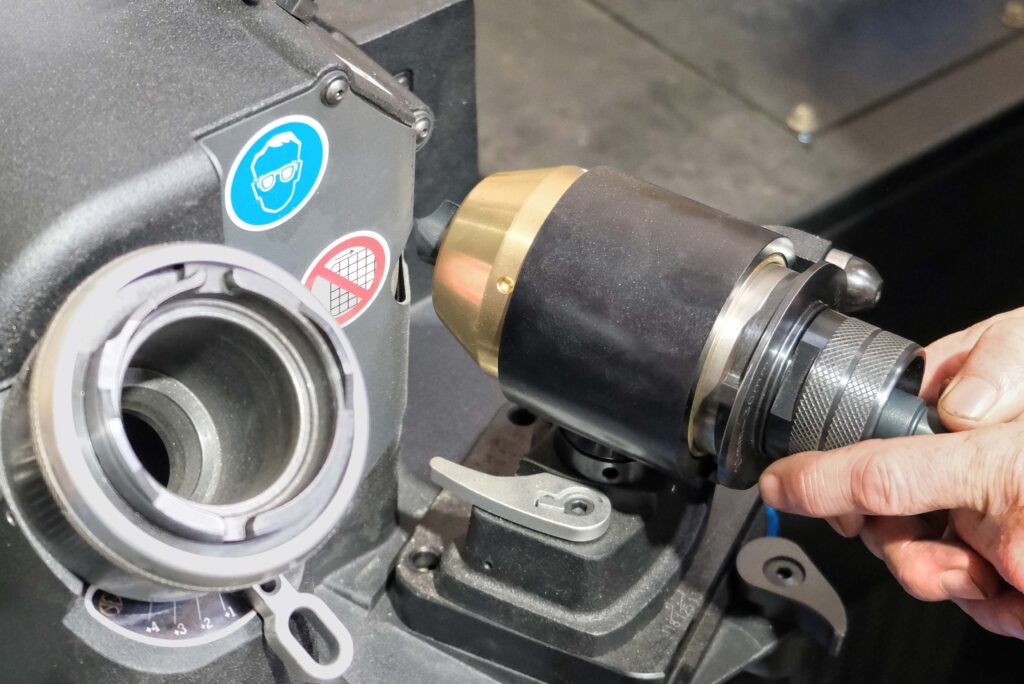

It resharpens bits in a three-step process. A drill is placed in a finger chuck, and the protrusion length is set at an alignment station. Carbide fingers enter the flute to fix the rotational orientation, and the drill is tightened in that position by rotating the chuck clockwise. The grinding motor is then started, and at a second station, the drill is sharpened on both sides while clamped in the same chuck. In an optional last operation, the chuck holding the sharpened drill is presented to a third station for point splitting to shorten the chisel line and lessen the force required for drilling components.

In conclusion, Mrs Toner observed: “The savings that the Darex XT-3000 brings make it an obvious investment once you realise the benefits. We wish we had done it much earlier. The sharpener paid for itself in less than six months, after which the ongoing monthly savings continue to add to the profit margin on all jobs that require drilling operations, which is most of them.”

“The sales arguments that 1st MTA make are difficult to ignore. We also purchase Chick workholding products from them, which have doubled productivity on one of our machining centres, and the supplier has also provided us with a new chuck for one of our lathes.”