Ceratizit delivers for CNF

When Aylesbury-based CNF Precision Engineering won a significant order to machine exhaust collector manifolds for a high-performance motorsport customer, the company called upon Ceratizit for additional support.

With over 50 years’ of machining components for the aerospace, defence, medical, electronic, and motor industries; utilising everything from two-axis lathes through to multi-pallet 5-axis machining centres, the issue faced by CNF was the complexity of the components. The parts came in six variants, along with the material from which they were made, 304 stainless steel.

“When we were faced with stainless steel that required extra long tool overhangs, we knew we would need additional technical input,” says Mark, CNF Precision Engineering’s Production Manager. With Ceratizit being a major supplier of workholding and tooling to CNF Precision, it was an easy decision to call in Nev Frisby their local technical sales engineer.

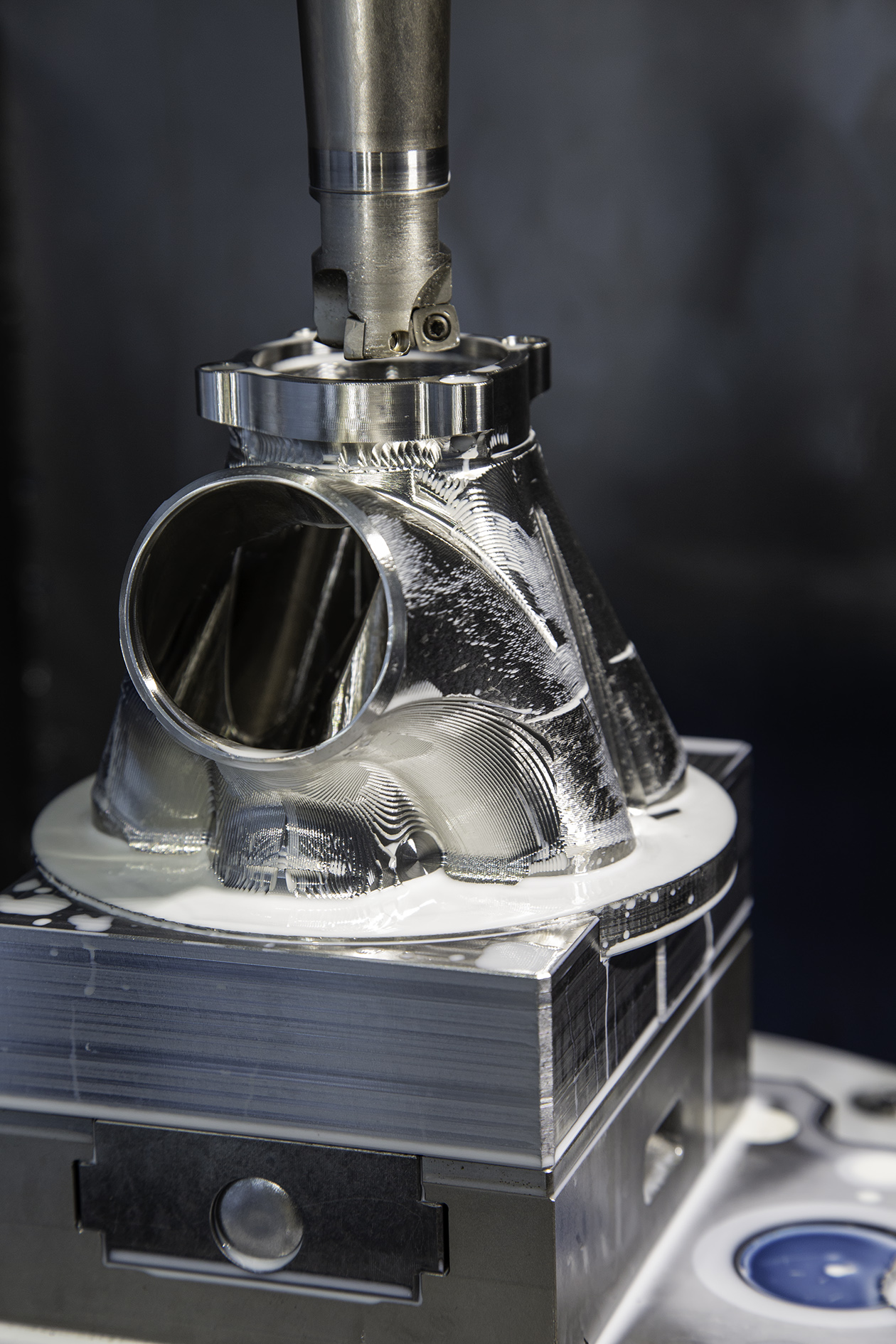

The manifolds had to be machined from stock billet material, so the first port of call was workholding, where Ceratizit’s MNG 3 location plates and ZSG 4 vices with bespoke jaws were used on CNF Precision’s 5-axis machining centre. Tooling posed a greater challenge due in part to the extensions that were needed and the intermittent cutting, the latter causing tool life issues. To reassure CNF Precision Engineering, Ceratizit provided a range of tooling on trial, with no commitment until the process had been completed. Key to that success was the 35mm diameter KUB Pentron indexable insert drills for the main internal port machining with 4XD flute length, along with a selection of high-feed indexable insert milling cutters using button and square inserts. The finishing was completed using Ceratizit’s Silverline solid carbide mills and Torus cutters.

The collaboration between CNF and Nev Frisby resulted in cycle time savings along with greatly improved tool life. For example, the indexable milling inserts are providing a 300% increase in tool life after testing a variety of carbide grades. The final grade of choice was Ceratizit’s CTCS245 grade for heat-resistant materials. A tool life gain up to 30% was seen when switching to Silverline cutters for finish milling from the previous competitor tool. In terms of cycle time, the work undertaken with the Ceratizit Torus cutters proved to be productive, with a decrease in cycle time upward of 50%. This was generated from the switch from a conventional ball nose cutter to a Ceratizit Torus Monstermill cutter.

With the project now running smoothly for CNF Precision Engineering, all of the tools used across the exhaust manifold variants have been loaded to the TOM840 tool vending unit. This ensures tools are available 24 hours a day if required. “The collaboration between Ceratizit and CNF highlights the support that we can provide on machining applications. This project threw up a variety of challenges, but the extensive range of tooling in our Ceratizit portfolio ensured that parts are being machined within the quoted cycle times with tooling costs minimised due to extended tool life,” concludes Nev Frisby.

With the project now running smoothly for CNF Precision Engineering, all of the tools used across the exhaust manifold variants have been loaded to the TOM840 tool vending unit. This ensures tools are available 24 hours a day if required. “The collaboration between Ceratizit and CNF highlights the support that we can provide on machining applications. This project threw up a variety of challenges, but the extensive range of tooling in our Ceratizit portfolio ensured that parts are being machined within the quoted cycle times with tooling costs minimised due to extended tool life,” concludes Nev Frisby.