🎧Ceramics optimise aerospace machining

As nickel-based alloy parts become increasingly prevalent in the aero sector, the demand for optimised cutting tools grows. Nickel-based materials exhibit poor machinability, adhere to cutting tools, and consist of abrasive particles within the alloy. These issues result in poor productivity when using carbide tools. Henri Sevonen, Senior Industry Segment Manager – Aerospace for metal cutting specialist Sandvik Coromant, explains how new ceramic end mill technology has emerged to meet these requirements.

Most aerospace parts are made from heat-resistant super alloys (HRSAs) and nickel-based alloys, which impose specific demands on engineers tasked with machining spools, turbine disks, combustion casings, and blisks. While many utilise solid-carbide end mills, these tools have limitations in performance.

In the global arena, aerospace machine shops are looking for next-level technologies to deliver a step-change in productivity and/or tool life. Ceramic end mills can provide that very leap, offering up to 20-30 times more machining speed than solid-carbide tools. Such gains can be achieved because ceramic cutters retain their hardness at the high temperatures which arise when machining nickel alloys.

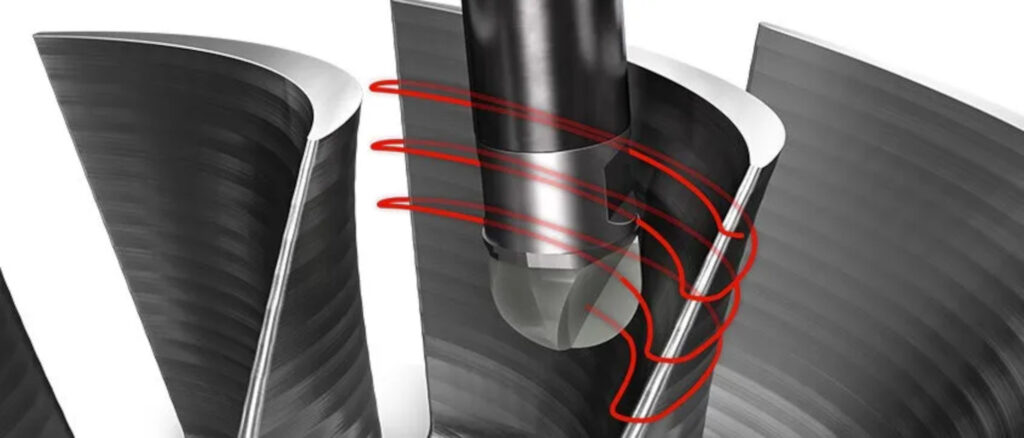

The brazed ceramic CoroMill® 316 exchangeable-head end mill for roughing serves as a productive solution for aero engine applications involving ISO S materials. Firstly, the exchangeable head concept provides inherent process flexibility. Additionally, a six-flute version with a straight corner radius is available, delivering productive side milling, alongside a four-flute version for face milling.

The ceramic substrate allows for a different cutting process in comparison with traditional solid-carbide tools. Importantly, the unique S1KU SiAlON grade is purpose-designed for the superior machining of nickel alloys, and is supported by negative geometry that provides a tough cutting edge. The latter also features a T-land for stable operations.

SiAlON carries a chemical composition of aluminium oxide and silicon nitride (Al203+Si3N4), a combination that promotes high wear resistance, even at elevated temperatures.

A stable set-up is recommended in all cases, and always without coolant application; machine shops should use pressurised air instead, as coolant would simply burn at the high temperatures involved. Furthermore, the use of coolant promotes thermal shocks and negatively affects tool life. Importantly, high spindle speeds of at least 13,000rpm are required. Additional recommendations include the use of down milling, as well as a programmed tool path that maintains the tool in constant contact with the material.

It is clear that nickel-based alloys will play a vital role in the future of aerospace manufacturing. However, there are many challenges facing those tasked with producing aerospace engine components. It’s only through continued tooling innovations, such as ceramic end mill technology, that aerospace machine shops will be able to optimise the machining process.